Comparisons of Pneumatic Ball Valves and Electric Ball Valves

Pneumatic ball valves

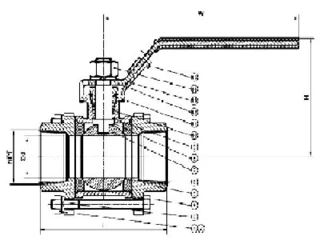

The pneumatic ball valve consists of the ball valve and the pneumatic actuator. It generally needs to be used in conjunction with accessories including the magnetic valve, air treatment FRL, limit switch, and positioner so as to be controlled remotely and locally as well as to be opened and closed in the control room. It improves safety, largely saves the cost of human resources and time, and makes manual control on site, above the ground and in dangerous palces not needed any more.

Classifications of pneumatic ball valves

The pneumatic ball valve consists of the ball valve and the pneumatic actuator. It generally needs to be used in conjunction with accessories including the magnetic valve, air treatment FRL, limit switch, and positioner so as to be controlled remotely and locally as well as to be opened and closed in the control room. It improves safety, largely saves the cost of human resources and time, and makes manual control on site, above the ground and in dangerous palces not needed any more.

Classifications of pneumatic ball valves

According to the material, pneumatic ball valves can be divided into stainless steel pneumatic ball valves, plastic pneumatic ball valves, sanitary pneumatic ball valves, carbon steel pneumatic ball valves, cast iron pneumatic ball valves, etc.

According to the connection mode, pneumatic ball valves can be divided into pneumatic flanged ball valves, screw thread pneumatic ball valves, welded pneumatic valves, etc.

According to pressure, pneumatic ball valves can be divided into low-pressure pneumatic ball valves, middle-pressure pneumatic ball valves and high-pressure pneumatic ball valves.

According to the channel position, pneumatic ball valves can be divided into throughway pneumatic ball valves, three-way pneumatic ball valves and right-angle pneumatic ball valves.

According to characteristics of the ball, pneumatic ball valves can be divided into floating ball valves and trunnion ball valves.

Floating ball

The ball of the floating ball valve is floating. Under the effects of medium pressure, the ball will shift and be tightly pressed on the sealing surface of the outlet end to ensure the sealing performance of the outlet end.

Fixed ball

The ball of the trunnion ball valve is fixed, and it will not shift after being pressed. All the trunnion ball valves are with the floating valve seat. Under the effects of medium pressure, the valve starts moving to make the sealing ring pressed on the ball so as to guarantee the sealing performance.

Electric ball valves

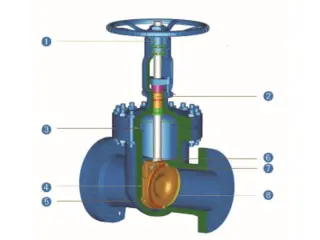

The electric ball valve is composed of the actuator and the ball valve. It is a kind of device which is used for the pipelines in the industrial automation and process control. To be specific, it is generally utilized for the remote on-off control of the pipelines' media.

According to the definition of the electric ball valve in the "Glossary of terms for valves", the electric ball valve is a kind of valve whose discs (balls) are driven by the valve stem, and then rotate around the axis of the valve. Electric ball valves are mainly used in cutting off and getting through media, or utilized for regualting and controlling media in the pipelines. As for the hard sealed V-shaped ball valve, there is a strong shear force between the V-shaped ball and the metal valve seat made of overlaying cemented carbide.

Comparisons between pneumatic ball valves and electric ball valves

Cost

The pneumatic ball valve has heavy load, but is cheaper than the electric ball valve. Thus, using pneumatic ball valves can reduce engineering cost.

Operational safety

Users who utilize the pneumatic ball valve can switch on or off the valve. When the electric ball valve has no power, it can only stay in its place, which presents that the pneumatic ball valve has great advantages on safety. Because when the electric ball valve is out of power, it will close so as to avoid the filter's backset and spillover. The pneumatic ball valve does not need electricity, whereas the electric ball valve uses 220V or three phase of 460V. So to say, the electric ball valve is more dangerous in a damp environment, whereas the pneumatic ball valve is not affected by the damp environment. About maintenance, it is easy to maintain the pneumatic ball valve because there is only one moving part. The electric actuator of the electric ball valve needs to be maintained by professionals due to more parts of the electric actuator.

Performance

The pneumatic ball valve can adapt to frequent full load. The electric ball valve is limited by the load capacity of motors and maximal start-up times per hour.

Life cycles

The pneumatic ball valve has the long life cycle with about 2 million actions. The repeatable usage rate of the pneumatic ball valve can be controlled accurately, which can almost reach 0.25%.

Corrosion resistance

The pneumatic ball valve with epoxy coating inside and outside the pneumatic actuator has great adaptability to the work environment. It can adapt to bad work environment such as flammable, explosive, dusty, ferromagnetic, radioactive, vibratory environment, etc.

Others aspects

When the pneumatic ball valve is not working properly, it can be repaired or replaced without power or air sources. About maintenance, the pneumatic ball valve does not need oil, whereas the electric ball valve needs a large amount of oil. About manual operation, the pneumatic ball valve can be operated without power. About speed, the pneumatic ball valve works and responses quickly so as to adjust accordingly. The speed of the electric ball valve is constant and can not be changed.

Send your message to this supplier

Related Articles from the Supplier

Advantage and Categories of Pneumatic Ball Valves

- Jun 24, 2014

Introduction of ball valves

- Aug 24, 2018

The Selection of Ball Valves

- Feb 26, 2021

Introduction to Electric PVC Ball Valves

- Dec 10, 2020

Related Articles from China Manufacturers

The Differences Between Ball Valves and Globe Valves

- May 10, 2019

Application of Small Electric Ball Valves

- Jul 31, 2022

Trim Numbers of Valves

- Feb 28, 2023

Related Products Mentioned in the Article

- Address: Xinhai Industry Zone, Sanqiao, Oubei, Wenzhou, Zhejiang, P. R. China.

- Phone: +86 577 6699 3222

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.valvemanufacturer.net/comparisons-of-pneumatic-ball-valves-and-electric-ball-valves.html