Y Type Check Valve: A Comprehensive Guide

Introduction

In modern industrial piping systems, valves are essential components for controlling fluid flow, ensuring safety, and maintaining efficiency. Among the various valve types available, the Y type check valve has earned recognition for its unique design, reliable performance, and ease of maintenance.

A Y type check valve is a non-return valve that permits fluid to flow in one direction while preventing reverse flow. Its Y-shaped body and internal spring-assisted mechanism make it particularly effective in reducing water hammer, a common issue in pipelines caused by sudden flow reversal. The angled design of the bonnet allows for easier maintenance, which is crucial in large-scale industrial operations where downtime can be extremely costly.

This article explores the structure, operation, materials, applications, maintenance, selection criteria, troubleshooting, and latest industry trends for Y type check valves. By understanding these aspects, engineers and plant operators can make informed decisions for fluid handling systems, ensuring reliability, efficiency, and safety.

What is a Y Type Check Valve?

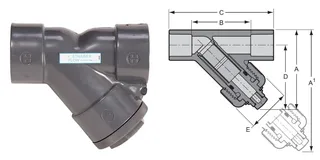

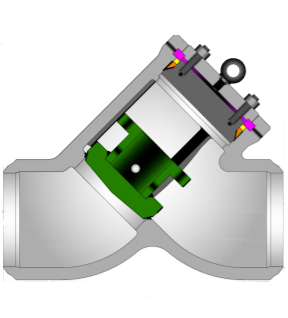

A Y type check valve is a type of non-return valve designed to allow flow in one direction only. Its distinctive Y-shaped body houses a spring-loaded disc, piston, or ball, which responds to differential pressure within the pipeline.

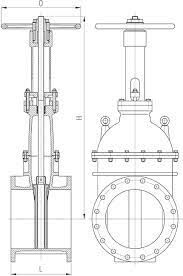

Structural Characteristics

Y-Shaped Body: The valve body forms a Y configuration, with the bonnet angled for accessibility.

Internal Mechanism: The disc or piston is either spring-assisted or gravity-assisted to ensure closure when flow decreases or reverses.

Sealing Surface: Typically made from materials such as stainless steel, carbon steel, or bronze, providing corrosion resistance and durability.

End Connections: Can be flanged, socket weld, threaded, or butt-welded to suit various piping systems.

Functionality

Forward Flow: Fluid pressure lifts the disc, compressing the spring if present, allowing flow through the valve.

Reverse Flow: When upstream pressure drops or flow reverses, the spring or gravity pushes the disc onto the seat, preventing backflow.

Silent Operation: The spring-assisted closure minimizes impact, reducing noise and vibration in the system.

The combination of Y-shaped design and spring assistance makes this valve a preferred choice in applications where system integrity and low noise are critical.

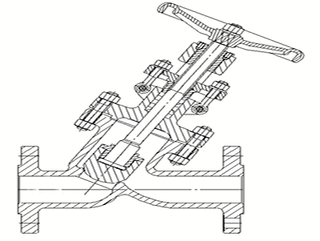

How Does a Y Type Check Valve Work?

The working principle of Y type check valves relies on pressure differences:

Opening: When the upstream (inlet) pressure exceeds downstream (outlet) pressure, the pressure difference overcomes the spring tension, lifting the disc and allowing fluid to pass.

Steady Flow: The disc remains open as long as inlet pressure is higher than outlet pressure, ensuring smooth flow.

Closing: When pressure drops or flow reverses, the spring pushes the disc back onto the seat, or gravity-assisted closure occurs in springless models.

Installation Guidelines

Horizontal Installation: Suitable for both spring-assisted and springless valves.

Vertical Installation: Springless valves must be installed with upward flow to ensure gravity assists closure.

Flow Direction: Always follow the flow arrow on the valve body to prevent malfunction.

Advantages of Spring-Assisted Designs

Faster closure, reducing water hammer.

Silent operation for sensitive systems.

Can be installed in multiple orientations without performance loss.

Key Features of Y Type Check Valves

Compact Y-Shaped Body: Reduces turbulence and energy loss while simplifying maintenance.

Spring-Assisted or Gravity-Assisted Closure: Ensures quick response to flow changes.

Silent Operation: Minimizes noise in industrial and commercial systems.

Low Pressure Drop: Optimized flow path ensures energy efficiency.

Robust Material Options: Stainless steel, carbon steel, bronze, and exotic alloys provide resistance to wear, corrosion, and high temperatures.

Maintenance-Friendly: The angled bonnet allows quick inspection, cleaning, or replacement without removing the valve from the pipeline.

Advantages Over Other Check Valves

Y Type vs. Swing Check Valves

Faster Closing: Spring-assisted discs reduce reverse flow quickly.

Compact & Accessible: Easier maintenance through bonnet access, unlike swing check valves requiring full removal.

Reduced Noise: Silent operation protects sensitive systems from vibration or sound issues.

Y Type vs. Lift Check Valves

Lower Pressure Drop: Smooth internal design reduces energy loss.

Simpler Maintenance: Inline inspection and part replacement is easier compared to lift check valves.

Y Type vs. Ball Check Valves

Reduced Wear: Even distribution of force prevents seat erosion.

Wider Applications: Performs better in high-pressure and high-temperature environments.

Applications of Y Type Check Valves

Y type check valves are versatile and widely adopted across multiple industries.

Water and Wastewater Systems

Prevent reverse flow in clean and contaminated water pipelines.

Reduce water hammer in pumps and treatment systems.

Oil and Gas Pipelines

Ensure safe transport of crude oil, natural gas, and refined products.

Withstand high pressures and fluctuating flow rates.

Chemical Processing

Resistant to corrosive chemicals when made with stainless steel or alloy materials.

Suitable for aggressive acids, bases, and solvents.

HVAC Systems

Regulate chilled water, hot water, and steam lines.

Silent operation prevents noise disruption in commercial buildings.

Power Plants

Protect turbines, condensers, and boilers from reverse flow damage.

Reduce maintenance costs by providing reliable non-return operation.

Marine and Seawater Applications

Used in cooling circuits, ballast systems, and bilge pumps.

Bronze or stainless steel construction provides excellent resistance to seawater corrosion.

Material Selection

Choosing the right material ensures durability, reliability, and compatibility with the fluid medium.

Stainless Steel (304/316): Corrosion resistance for aggressive environments.

Carbon Steel: High-pressure, high-temperature pipelines.

Bronze/Brass: Marine and HVAC applications.

Exotic Alloys (Duplex, Monel, Hastelloy): Highly corrosive or chemical industries.

Material selection must also consider fluid temperature, pressure, pH level, and particulate content to ensure long-term valve performance.

Maintenance and Inspection

Maintenance is a significant advantage of Y type check valves:

Routine Inspection: The bonnet can be opened for visual inspection without pipeline disassembly.

Cleaning: Remove scale, dirt, or sediment to maintain optimal flow.

Replacement: Springs, discs, and seats can be replaced quickly.

Lubrication: Minimal to none is required, but certain designs may benefit in extreme environments.

Regular inspection prevents unexpected downtime and extends valve life.

Installation Best Practices

Proper installation ensures the valve functions optimally and reduces maintenance needs:

Verify flow direction with the arrow on the valve body.

Use proper gaskets and torque specifications for flange connections.

Avoid excessive pipeline vibration or stress, which may affect valve sealing.

Support heavy pipelines to prevent valve body distortion.

Consider upstream straight pipe lengths to stabilize flow and minimize turbulence.

Troubleshooting Common Issues in Y Type Check Valves

Despite their reliable design and widespread use, Y type check valves can occasionally experience operational issues that affect performance and system efficiency. Understanding these common problems and their solutions is essential for maintaining smooth pipeline operations.

Valve Fails to Close: One of the most frequent issues occurs when the valve does not fully seal, allowing reverse flow. This can be caused by debris or sediment trapped in the valve seat, a damaged or weakened spring, or improper installation. Regular inspection and cleaning of the internal components can prevent this problem.

Excessive Noise: Unusual noise, often described as banging or rattling, may indicate incorrect spring tension, misalignment during installation, or sudden flow surges. Ensuring the valve is installed according to manufacturer guidelines and verifying spring integrity can minimize noise issues.

Leakage: Leakage around the valve seat or disc can occur due to wear, erosion, or corrosion over time. Routine inspection and timely replacement of worn components are critical to maintain a tight seal and prevent fluid loss.

High Pressure Drop: A pressure drop higher than expected can result from incorrect valve sizing, excessive flow velocity, or internal obstructions. Confirming the valve is properly sized for the pipeline and fluid characteristics is essential.

Implementing a structured maintenance program—including periodic inspection, cleaning, and part replacement—can significantly reduce these issues, ensuring reliable and efficient valve operation over the long term.

Industry Trends

Y type check valves are evolving with industrial needs:

Smart Valves: Integration with sensors for flow monitoring and predictive maintenance.

Advanced Alloys: Duplex and high-nickel alloys enhance corrosion resistance.

Energy Efficiency: Optimized internal design for minimal pressure loss.

Compact Designs: Lighter, smaller valves for modular and skid-mounted systems.

These trends align with the global push for automation, sustainability, and efficiency in industrial systems.

Case Studies

Case Study 1: Water Treatment Plant

A municipal water treatment facility replaced swing check valves with Y type check valves in high-pressure pumping stations. Result:

Reduced water hammer by 80%.

Maintenance downtime decreased by 50%.

Energy savings due to lower pressure drop across valves.

Case Study 2: Chemical Processing Plant

A chemical plant handling corrosive acids installed Y type check valves with stainless steel internals:

Achieved extended valve lifespan in aggressive chemical conditions.

Easy in-line maintenance reduced shutdown periods.

Silent operation improved working conditions in the plant.

Selection Criteria

When choosing Y type check valves, consider:

Pipe Size & Pressure Rating: Match system requirements.

End Connection Type: Flanged, threaded, or welded based on application.

Flow Characteristics: Ensure low pressure drop and adequate flow capacity.

Material Compatibility: Consider fluid type and temperature.

Standards Compliance: Look for API, ASME, ISO, or EN-certified valves.

Installation Orientation: Select spring-assisted or springless designs accordingly.

Proper selection ensures reliability, efficiency, and longevity.

Conclusion

The Y type check valve is a versatile, durable, and highly reliable solution for controlling fluid flow in pipelines. Its Y-shaped body, spring-assisted closure, and easy maintenance provide significant advantages over swing, lift, and ball check valves.

From water treatment and chemical plants to HVAC systems and power generation, Y type check valves prevent reverse flow, reduce water hammer, and minimize maintenance downtime.

With innovations in materials, smart monitoring, and compact design, Y type check valves are evolving to meet the demands of modern industrial systems. Their ability to combine safety, efficiency, and accessibility makes them indispensable in critical fluid handling operations worldwide.

Send your message to this supplier

Related Articles from the Supplier

Y Type Check Valve: A Comprehensive Guide

- Sep 24, 2025

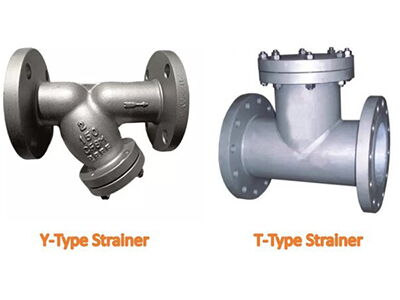

An Introduce to a Y-strainer

- Apr 26, 2021

Related Articles from China Manufacturers

For Stock: Y-Type Piston Check Valve

- Jul 25, 2025

An introduction to Y-type and T-type Strainers

- Jun 18, 2020

Y-Type vs. T-Type Strainers

- Jul 11, 2025

Selection Principles of Y-Type Filters

- Apr 11, 2024

Related Products Mentioned in the Article

Supplier Website

Source: https://www.mfrsvalve.com/news/y-type-check-valve-a-comprehensive-guide.html