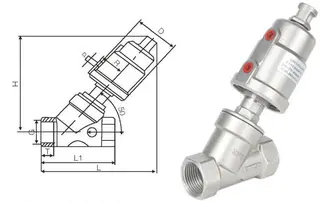

Pneumatic Angle Seat Valve, A351 CF8/CF8M, DN8-DN100, PN16/25

Product Name: Pneumatic Angle Seat Valve

Body Material: ASTM A351 CF8/CF8M

Nominal Diameter: DN8-DN100, 1/4-4 Inch

Nominal Pressure: PN16, PN25, Class 150-300 LB, 1.6/2.5Mpa

Connection Method: Threaded

Valve Core Seal: PTFE/PPL/PEEK/Metal Seal

Piston Seal: FKM/NBR

Valve Stem Seal: PTFE/PPL/FKM/Graphite

Medium Temperature: -10°C to 450°C (For high temperature and high pressure, please provide detailed working conditions for selection)

Control Pressure: 0.3-0.8Mpa

Applicable Medium: Water/Alcohol/Steam/Neutral Gases or Liquid Acid-Alkali Solutions, etc.

Installation Direction: Forward/Reverse (Install according to needs, try to make the actuator face up)

Applications of Pneumatic Angle Seat Valves

They are widely used in food and chemical processes, sterilizers, high-pressure disinfection washers, and dry washers in beer production lines. Compared to traditional angle seat valves, they have the following new features:

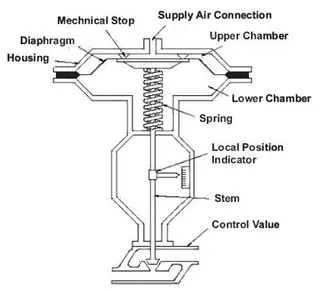

Visual position indicator for limit switch or emergency manual operation.

Easy installation: The pneumatic actuator can rotate 360°, and even the limit switch can rotate 360°. It is convenient to install one or two limit switches.

Advanced pneumatic actuator: With a thick engineering plastic shell, it is safe and reliable. The low-wear piston structure has a large capacity and low air consumption. The internal components are self-lubricating and maintenance-free.

Various control methods: Normally open, normally closed, and double acting.

Requires a smaller pneumatic actuator: When the fluid flows from the upper side of the valve stem, a smaller control head can be selected.

Easy connection: MAMUR standard connection, embedded metal joint.

Long life guide rod: The valve stem is sealed with PTEE to prevent dirt from entering. It is self-lubricating and maintenance-free. The valve stem is specially treated to ensure precise positioning and can automatically return to the correct position.

No water hammer effect: When the fluid flows from the lower side of the valve stem, the water hammer (water impact force) is absorbed.

Advanced valve body structure: The flow capacity is one-third larger than that of ordinary angle seat valves, with a smaller volume and better fluid dynamics.

Pneumatic Angle Seat Valve Dimension Table

|

Specification |

Actuator |

L1 |

L |

H |

D |

P |

Maximum Working Pressure (MPa) |

Air Source Pressure (MPa) |

|

DN15 |

50 |

68 |

140 |

135 |

62 |

G1/8 |

PN25 |

4-10P |

|

DN20 |

50 |

75 |

145 |

140 |

62 |

G1/8 |

||

|

DN25 |

50 |

90 |

155 |

145 |

62 |

G1/8 |

||

|

DN25 |

63 |

90 |

175 |

160 |

76 |

G1/8 |

||

|

DN32 |

63 |

115 |

193 |

175 |

76 |

G1/8 |

||

|

DN40 |

63 |

115 |

195 |

185 |

76 |

G1/8 |

||

|

DN50 |

63 |

135 |

205 |

200 |

76 |

G1/8 |

||

|

DN50 |

80 |

135 |

230 |

235 |

100 |

G1/8 |

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Pneumatic Valves Used in Water Supply System

- Sep 23, 2016

Pneumatic Valves Used in Water Supply System

- Apr 08, 2015

How Does A Pneumatic Butterfly Valve Work

- Apr 06, 2017

Pneumatic butterfly valves installation guide

- Oct 12, 2018

What is a Pneumatic Actuator and how does it Work?

- Jun 17, 2020

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/pneumatic-angle-seat-valve-a351-cf8-cf8m-dn8-dn100-pn16-25.html