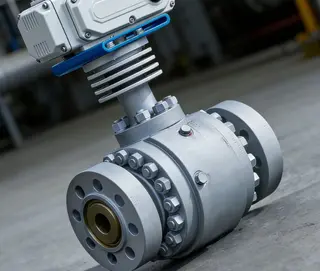

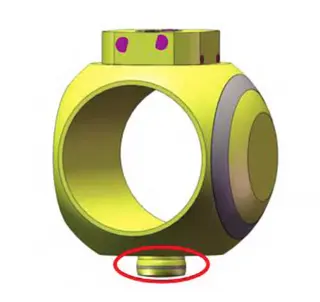

High-Pressure Ball Valve Seat, Graphite/Inconel, 369*357 mm

Product Name: High-Pressure Hard-Seal Ball Valve Seat, Graphite Seat

Model: MAX900S

Specification: 369 mm * 357 mm

Material Properties:

Graphite Purity: ≥99%

Metal Wire Content: 20% (Inconel 600)

Sulfur Content: ≤50 PPM

Chlorine Content: ≤20 PPM

Technical Requirements

Degreasing & Oil Removal: Yes

Testing Medium: Nitrogen

Test Pressure: 4 MPa

Sealing Performance: Zero leakage under nitrogen pressure test

Key Advantages

Zero Gas Leakage: Meets stringent nitrogen sealing requirements.

Durability: Prevents expansion-induced cracking common in traditional designs.

Custom Solutions: Available for high-pressure gas sealing challenges.

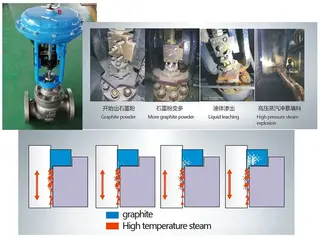

Challenges & Solutions

High-Difficulty Sealing: Achieving gas-tight sealing without prior hydrostatic testing is extremely challenging for hard-seal ball valves. Traditional graphite rings often expand after water testing, leading to failure in subsequent gas tests.

Innovative Process: Our advanced manufacturing process ensures graphite rings pass nitrogen sealing tests directly after degreasing, without hydrostatic testing.

50 Units Delivered: All 50 high-pressure ball valves passed pressure testing on the first attempt.

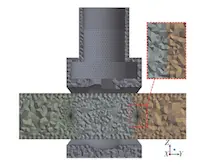

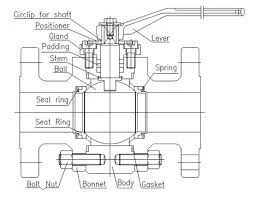

Design Optimizations

Density & Weaving Analysis: Customized graphite density and tape weaving based on valve drawings to maximize radial expansion under compression.

Uniform Metal Wire Distribution: 20% Inconel 600 wire is evenly distributed to prevent localized high-density zones, ensuring consistent sealing performance.

Contact Us: If you face high-pressure gas sealing difficulties, our team can provide tailored solutions.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/high-pressure-ball-valve-seat-graphite-inconel-369-357-mm.html