High-Pressure, High-Flow Ball Valve Sealing Simulation Study

Abstract

This paper investigates the sealing performance of high-pressure, high-flow ball valves. Traditional sealing design methods often prove inadequate for meeting the demands of complex operating conditions. Therefore, simulation technology is employed to analyze sealing behavior. The operating principles and structural features of ball valves are presented, followed by an examination of the sealing mechanism and the influence of materials, structure, and operating conditions on sealing performance. A simulation model is developed using finite element analysis, contact mechanics theory, and multi-physics coupling analysis. After simplifying the model, defining material parameters, and applying boundary conditions, the simulation results are analyzed. The results include the contact stress distribution on the sealing surface, deformation of the sealing structure, and leakage behavior. Based on these findings, the sealing structure is optimized by adjusting the geometry of the sealing surface, material properties, and structural parameters. An experimental setup was constructed to collect validation data, and comparison of the simulation and experimental results confirmed the model’s accuracy. The study demonstrates that the optimization measures substantially enhance sealing performance and that the simulation model is reliable. Future research on sealing simulation will focus on refinement, multi-physics coupling, and intelligent approaches, aiming to provide effective solutions for improving the sealing performance of high-pressure, high-flow ball valves and addressing the needs of industrial development.

Introduction

In modern industrial systems, high-pressure, high-flow ball valves serve as core fluid control equipment and play an indispensable role in the oil, gas, and chemical industries. Their sealing performance directly impacts system safety, energy efficiency, and overall production reliability. As industrial scale continues to expand and process flows become increasingly complex, the sealing requirements for high-pressure, high-flow ball valves have grown more stringent. Traditional seal design and analysis methods for ball valves are increasingly inadequate under complex operating conditions and cannot fully satisfy the requirements of today’s high-performance applications. The rapid development of computer-based simulation technology has opened new opportunities for sealing research. Seal simulations provide deeper insights into the underlying mechanisms of ball valve sealing, supporting the optimization of sealing structures and parameters, and thereby improving sealing reliability. This is of considerable practical importance for ensuring safe, efficient, and uninterrupted industrial production.

I. Overview of High-Pressure, High-Flow Ball Valves

High-pressure, high-flow ball valves primarily consist of key components, including the valve body, ball, seat, and stem. Their operating principle involves opening and closing the valve by rotating the ball via the stem. When closed, the ball fits snugly against the valve seat, forming an effective seal that prevents leakage. When open, the ball rotates to align with the flow channel, allowing the medium to pass freely. Under high-pressure, high-flow conditions, these valves must not only withstand significant pressure loads but also ensure smooth medium flow, posing considerable challenges to both structural strength and sealing performance. Compared with conventional ball valves, high-pressure, high-flow ball valves exhibit three distinctive features:

(1) larger diameters to accommodate high-volume media transport;

(2) higher pressure ratings, allowing them to withstand more demanding operating conditions; and

(3) extremely stringent sealing requirements, since even minor leakage can lead to serious safety incidents and significant economic losses. However, these characteristics also pose challenges in seal design and manufacturing, including wear and deformation of the sealing surfaces and the difficulty of preventing leakage under high-pressure conditions.

II. Ball Valve Sealing Principle and Influencing Factors

1. Sealing Principle

The sealing function of a ball valve is primarily achieved through close contact between the ball and the valve seat. When the valve is closed, the seat forms a seal with the ball surface under the combined action of preload and medium pressure. To prevent leakage, sufficient contact stress must be maintained at the sealing interface to fill microscopic gaps between the surfaces. The elastic deformation capacity of the sealing material is also crucial, as it enables the sealing surface to conform more effectively to the ball, thereby significantly enhancing sealing performance.

Figure 1. Schematic diagram of ball valve structure

2. Factors Affecting Sealing Performance

The properties of the sealing material—including hardness, elastic modulus, and coefficient of friction—play a decisive role in sealing performance. A material with suitable hardness offers wear resistance while permitting moderate elastic deformation under pressure, ensuring effective sealing. The elastic modulus determines how much a material deforms under load; an appropriate modulus ensures consistent surface contact across varying operating conditions. The coefficient of friction affects the interaction between sealing surfaces; excessive friction accelerates wear and compromises sealing performance. Besides material properties, structural parameters—such as ball diameter, seat width, and sealing surface taper angle—are critical. The ball diameter influences both flow capacity and stress distribution on the sealing surface. A seat width that is too narrow can lead to insufficient sealing area and higher leakage risk, whereas an excessively wide seat increases material costs and overall valve size. The taper angle of the sealing surface directly affects stress distribution and sealing performance; an inappropriate angle can create localized stress concentrations, resulting in leakage. Operating conditions also play a crucial role. High pressure increases the load on the sealing surface, potentially causing deformation, wear, or even failure. Elevated temperatures can degrade sealing materials, diminishing elasticity and sealing effectiveness, while excessive flow rates may erode the sealing surface, accelerating wear. Corrosive media can chemically attack sealing materials, damage surface integrity, and significantly reduce sealing performance.

III. Fundamentals of Seal Simulation Technology

1. Finite Element Analysis (FEA)

Finite element analysis is a widely used numerical method in seal simulation studies. It discretizes the ball valve sealing structure into a finite number of elements and, by solving the governing mechanical equations for these elements, determines the stress and strain distribution throughout the entire structure. In ball valve seal simulations, FEA can replicate the contact conditions of sealing surfaces, the distribution of contact stress, and the deformation of the sealing structure under various operating conditions. By constructing a well-defined finite element model, the effects of various factors on sealing performance can be accurately assessed, providing a solid theoretical basis for optimized seal design.

2. Contact Mechanics Theory

Contact mechanics theory examines the mechanical behavior between two interacting surfaces. In ball valve seal simulations, it is used to analyze the interaction between the ball and the valve seat. This approach enables the calculation of key parameters, including contact pressure, friction, and deformation at the sealing interface. These parameters are crucial for evaluating sealing performance, providing researchers with deeper insight into sealing surface behavior and allowing precise identification of potential leakage points.

2. Multi-Physics Coupling Analysis

In real operating conditions, ball valve sealing performance is affected by the combined influence of multiple physical fields, including pressure, temperature, and flow. Multi-physics coupling analysis accounts for the interactions among these fields, enabling more realistic simulations of valve behavior. For example, under high-temperature and high-pressure conditions, the pressure field can deform the sealing structure, which in turn affects the temperature distribution. Temperature variations subsequently influence the properties and performance of the sealing material. By capturing these complex interactions, multi-physics coupling analysis offers a more comprehensive understanding of sealing mechanisms and aids in developing more effective solutions to enhance sealing performance.

IV. Establishing a Simulation Model for a High-Pressure, High-Flow Ball Valve Seal

1. Model Simplifications and Assumptions

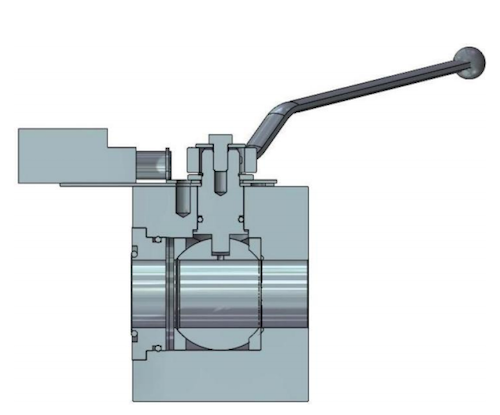

To facilitate simulation analysis, appropriate simplifications and assumptions were applied to the actual structure of the high-pressure, high-flow ball valve. Minor features, such as small holes and chamfers on the valve body, were omitted, as they do not significantly impact the accuracy of the sealing performance analysis. The sealing surface was assumed to be smooth, and the material was considered uniform and continuous; microscopic manufacturing defects were not included in the model. These assumptions enhance computational efficiency while maintaining acceptable accuracy. ANSYS Workbench was employed to simulate the pressure distribution between the ball and the valve seat during contact. To improve computational speed, the model was simplified in Design Modeler by removing local features with negligible impact, retaining only the ball and gasket components. The resulting model is shown in Figure 2. Due to its irregular geometry, automated meshing was applied, with a cell size of 1.5 mm, a total of 57,000 elements, and a minimum element size of 0.12 mm. The mesh quality was within acceptable limits. Contact was defined as frictional, with a coefficient of friction of 0.15.

Figure 2. Ball Valve Assembly Model

3. Material Parameter Settings

Material parameters were specified based on the sealing and structural materials used in the ball valve. For the sealing material, properties including elastic modulus, Poisson’s ratio, hardness, and friction coefficient were specified. For structural components, such as the valve body and ball, parameters including elastic modulus, Poisson’s ratio, and density were defined. Since the reliability of the simulation results depends directly on the accuracy of these parameters, the data were obtained from experimental testing or authoritative reference sources.

3. Application of Boundary Conditions

Boundary conditions were applied to replicate the actual operating environment of the ball valve. In seal simulations, the primary boundary conditions include medium pressure, preload, and mechanical constraints. Medium pressure, reflecting operating conditions, was applied to the contact surface between the ball and the seat. Preload was simulated by applying a specified displacement to the valve seat to ensure adequate initial contact pressure at the sealing interface. Constraint conditions were applied to components such as the valve body and stem, consistent with the installation method and operating conditions, to restrict unwanted displacement and rotation.

V. Analysis of Seal Simulation Results

1. Contact Stress Distribution on the Sealing Surface

Seal simulation allows the evaluation of contact stress distribution on the sealing surface under different operating conditions. The uniformity of this distribution directly affects sealing effectiveness. Uneven contact stress can lead to localized wear and leakage at the interface. Detailed analysis of the stress distribution helps accurately identify weak areas on the sealing surface, providing a solid basis for structural optimization. For example, if excessive stress is concentrated in a specific region, sealing performance can be improved by adjusting the sealing surface geometry or increasing the material strength in that area.

2. Deformation Analysis of the Sealing Structure

Under high pressure and other demanding conditions, the sealing structure of a ball valve deforms, which can significantly affect the contact state and overall sealing performance. Simulating structural deformation clarifies how these changes impact sealing integrity. Excessive deformation can cause partial separation of the sealing surfaces, leading to leakage. Based on deformation analysis, targeted improvements—such as optimizing the structural design or selecting more appropriate materials—can be implemented to minimize deformation and ensure reliable sealing performance.

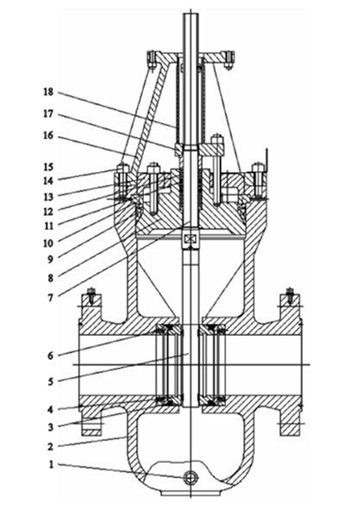

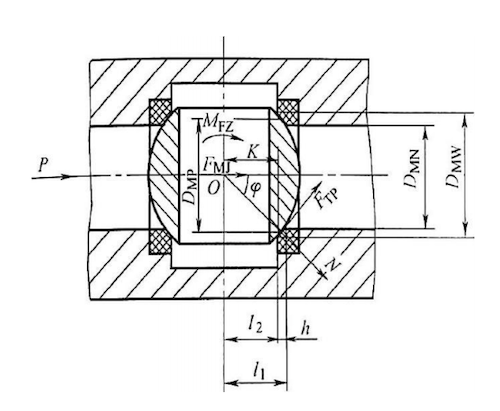

Figure 3. Force diagram of the seat seal ring at the outlet of a floating ball valve

3. Leakage Calculation and Evaluation

Leakage is a key indicator of ball valve sealing performance. Simulation enables the calculation of leakage under various operating conditions, with results assessed against relevant standards and project-specific requirements. If leakage exceeds allowable limits, further optimization of the sealing structure or adjustment of sealing parameters is necessary to reduce leakage and ensure compliance with performance standards.

VI. Seal Structure Optimization Based on Simulation Results

1. Optimization of Sealing Surface Shape

Based on seal simulation results, the geometry of the sealing surface can be optimized. For example, adjusting parameters such as the taper angle and curvature radius can produce a more uniform contact stress distribution, thereby improving sealing performance. Numerical optimization algorithms, combined with the simulation model, can automatically identify optimal sealing surface parameters. The resulting optimized geometry effectively reduces leakage and significantly enhances the sealing reliability of the ball valve.

2. Improvement of Sealing Materials

Based on the performance limitations of sealing materials under various operating conditions identified through simulation analysis, more suitable materials can be selected, or existing materials can be enhanced. For example, for ball valves operating under high-temperature conditions, materials with superior heat resistance can be selected. For corrosive environments, corrosion-resistant sealing materials are preferred. Additionally, material modification techniques can be used to enhance hardness, elasticity, and wear resistance, further optimizing sealing performance.

VII. Conclusion

In summary, this study on the sealing simulation of a high-pressure, high-flow ball valve provides a comprehensive analysis of the sealing principles and the key factors influencing sealing performance. A detailed simulation model was developed for in-depth analysis and optimization. The results indicate that contact stress distribution on the sealing surface, deformation of the sealing structure, and leakage are closely related to overall sealing performance. By optimizing the sealing surface geometry, enhancing sealing materials, and adjusting structural parameters, the sealing performance of the ball valve can be effectively improved. Experimental validation confirms the high accuracy and reliability of the simulation model, providing robust technical support for the design and optimization of ball valve sealing systems.

Send your message to this supplier

Related Articles from the Supplier

High-pressure Angle Globe Valves in ASTM A182 F22

- Dec 17, 2021

High-pressure Aluminum Bronze Valves for Sea Water

- Feb 13, 2023

Extra High Pressure Y-type Globe Valves

- Nov 16, 2021

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.baltic-valve.com/high-pressure-high-flow-ball-valve-sealing-simulation-study.html