The Difference Between Gate Valves and Globe Valves

What Is the Difference Between Gate Valves and Globe Valves? How to Choose Appropriate Valves?

What is the difference between gate valves and globe valves? How to choose the appropriate valve? Gate valves and globe valves each have their own advantages, disadvantages, and applicable scenarios. Gate valves are suitable for high flow, fully open or fully closed pipeline systems, while globe valves are suitable for precise flow regulation and situations requiring good sealing. It is recommended to make reasonable decisions when selecting valves based on specific working conditions, flow control requirements, and the working environment of the pipeline. Understanding the characteristics and applicable scenarios of gate valves and globe valves can help engineering and technical personnel ensure the stability and safety of the system in practical operations.

1. Basic definitions and working principles of gate valves and globe valves

Gate valves and globe valves are important equipment for controlling fluid flow, but their working methods and usage environments are different. Firstly, we need to understand the basic definitions and working principles of both.

(1) Gate valves: A gate valve is a type of opening and closing device used for fluid flow in pipelines. It mainly cuts off or opens fluid channels by moving the gate up and down. The opening and closing action of a gate valve is a linear motion, which controls the fluid by rotating the valve stem to drive the lifting and lowering of the valve plate. Gate valves are suitable for pipeline systems with infrequent fluid flow regulation and are typically used in fully open or fully closed conditions.

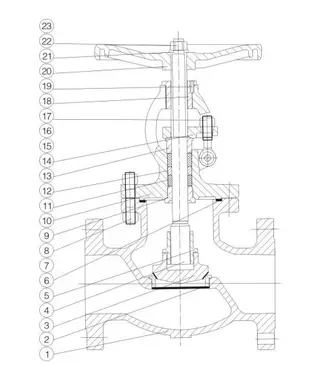

(2) Globe valves: A globe valve is a device that controls fluid flow by sealing the valve disc and seat, and its structural design allows for more precise flow regulation. Unlike gate valves, globe valves mainly rely on the up and down movement of the valve disc to achieve fluid opening and closing, and usually use rotational motion to operate the valve. Globe valves are suitable for applications that require precise flow control, especially in high-pressure and high-temperature environments where they perform well.

2. The main differences between gate valves and globe valves

Although both gate valves and globe valves can be used for fluid control, they have significant differences in structure, operation mode, and scope of application.

(1) Structural differences

Gate valves: The internal structure of a gate valve mainly includes components such as the gate plate, valve seat, and valve stem. The gate moves up and down along the valve seat during opening and closing, and the fluid flows through the gate valve without any obstacles. Gate valves have a simple structure, quick opening and closing, and generally use flange or threaded connections.

Globe valves: The structure of a globe valve is relatively complex, mainly including components such as valve disc, valve seat, and valve stem. The valve disc moves up and down inside the valve seat, regulating the flow of fluid through the contact between the valve stem and the valve seat. Compared to gate valves, globe valves have more internal components, which require greater torque during the opening and closing process.

(2) Differences in working methods

Gate valves: The opening and closing of a gate valve is achieved through the vertical lifting and lowering of the gate plate, which usually requires less operating force. It opens and closes quickly, but gate valves are mainly used to fully open or completely close fluid flow and are usually not used for precise flow regulation. When fluid passes through, the impact of the fluid on the gate is relatively small, therefore, gate valves are suitable for pipeline systems that require frequent opening and closing and stable flow.

Globe valves: The sealing contact is used by globe valves between the valve disc and the valve seat to regulate the flow rate of the fluid, and the opening and closing action is slow. Globe valves usually have high sealing performance and can effectively control flow, making them particularly suitable for situations that require precise flow regulation or work under high pressure conditions.

(3) Differences in scope of application

Gate valves: Gate valves are generally used in situations where complete fluid opening and closing is required, suitable for high flow, high pressure, and wide temperature range working conditions, such as oil, natural gas, and other transportation pipelines. Due to its relatively simple opening and closing operation, gate valves have a wide range of applications.

Globe valves: Globe valves are commonly used in precision flow control applications and are suitable for regulating pipeline systems with significant changes in flow, temperature, and pressure. Especially in pipelines that require high sealing, corrosion resistance, and high pressure resistance, globe valves have more advantages.

(4) Comparison of advantages and disadvantages

The advantages of gate valves include quick opening and closing, easy operation, and low fluid resistance, but the disadvantage is poor adjustment accuracy, especially in low flow rates where flow cannot be well controlled. The sealing performance of gate valves is relatively poor, which may cause wear on the sealing surface during frequent opening and closing.

The advantages of globe valves are good sealing and high flow regulation accuracy, especially suitable for extreme working conditions such as high temperature and high pressure. Its disadvantage is that the operation is relatively cumbersome and requires a relatively large torque to open and close.

3. How to choose appropriate valves?

When selecting gate valves and globe valves, it is necessary to determine which valve is more suitable based on specific operating conditions. Here are several considerations when choosing a valve.

(1) The requirement for flow control: If the pipeline needs to adjust the flow and the control accuracy is high, a globe valve should be selected. If only complete opening and closing of the pipeline is required and the flow rate is relatively stable, a gate valve is a more suitable choice.

(2) Working pressure and temperature: For high-pressure and high-temperature pipelines, choosing a globe valve may be more suitable because it can provide higher sealing and better flow control. Although gate valves can also be used under these operating conditions, their sealing and pressure resistance are slightly inferior.

(3) Operating frequency: If the valve needs to be opened and closed frequently, gate valves should be preferred because their opening and closing actions are rapid and suitable for high-flow, high-pressure working environments. If the opening and closing are rare and there is a high- demand for flow control, a globe valve can be selected.

Send your message to this supplier

Related Articles from the Supplier

The Difference Between Gate Valves and Globe Valves

- Sep 30, 2025

The Difference Between Ball Valves and Gate Valves

- Jan 08, 2025

Related Articles from China Manufacturers

The Difference between Globe Valves and Gate Valves

- Jun 26, 2022

The Difference between Globe Valves and Gate Valves

- Aug 02, 2023

The Difference Between Gate Valve and Globe Valve

- Aug 23, 2018

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeevalve.com/the-difference-between-gate-valves-and-globe-valves.html