Structural Analysis of Pneumatic V-shaped Ball Valves

The structural design of the pneumatic V-shaped ball valve revolves around the core functions of "precise adjustment+ reliable sealing+ pneumatic drive", and can be disassembled into four modules: drive unit, execution unit, control unit, and auxiliary unit. Each part works together to achieve fluid cutoff and flow regulation.

(1). The core structure composition and functions

1. Drive unit: Power source (pneumatic actuators)

The pneumatic actuator is the power core of valve action, which drives the piston or diaphragm to move through compressed air, drives the valve stem to rotate, and realizes the opening and closing or adjustment of the ball valve.

Common types

Double acting actuators: it requires separate control of valve opening or closing by positive and negative compressed air and fast action speed. It is suitable for large caliber or high pressure working conditions.

Single acting actuators: it is equipped with a built-in reset spring, and only one compressed air is needed to drive the valve action (such as opening). After the gas is cut off, it will be automatically reset by the spring (such as closing). It is suitable for scenarios that require "fault safety" such as flammable, explosive, toxic media, etc.

Key components: cylinder, piston or diaphragm, reset spring (single acting), air source interface, stroke adjustment bolt.

2. Execution Unit: Fluid Control Core (Valve Body Components)

The valve body component is the part that directly contacts and controls the fluid, and the core lies in the design of the "V-shaped sphere+ special valve seat", which determines the adjustment accuracy and sealing performance of the valve.

V-shaped spheres

There is a V-shaped incision on the sphere (commonly at angles of 15 degrees or 30 degrees or 45 degrees or 60 degrees or 90 degrees) with sphere+ special incision accuracy.

During rotation, the "involute" contact between the V-shaped notch and the valve seat are used to achieve precise adjustment of flow rate (especially with high sensitivity when the opening is small)

Valve seats

We often use elastic materials such as PTFE and polytetrafluoroethylene PCTFE, metal hard seal. It is classified as soft seal types or hard seal ones.

Tightly adhere to the V-shaped sphere to achieve sealing (prevent medium leakage). Soft seals are suitable for low-pressure, room temperature, and clean media, while hard seals (metal to metal) are suitable for high-temperature, high-pressure, and particulate media.

Valve stems

It is made of stainless steel material, with anti-corrosion treatment on the surface (such as chrome plating). It is connected to the sphere and actuator through keys or pins to transmit torque.

Connect the driving unit and the executing unit, transmit the rotational force of the executing mechanism to the sphere, and control the rotation angle of the sphere.

3. Control unit: precise action control

Positioner: a core control component that receives external 4-20mA current signals (or 0-10V voltage signals), converts the signals into air pressure signals, accurately controls the action stroke of the actuator, ensures that the rotation angle of the sphere corresponds linearly with the input signal, and achieves precise adjustment of flow rate.

Electromagnetic valves: it is used to control the on or off direction of compressed air and achieve remote switch control of the valve. When combined with a single acting actuator, the "gas cut-off reset" function can be achieved.

Limit switch: it is installed on the actuator. Feedback the position signal of the valve "fully open" and "fully closed" through mechanical contacts or proximity sensors. And it is used for remote monitoring of the valve status.

4. Auxiliary unit: Ensure stable operation

Packing box and packing: it is located at the gap between the valve stem and valve body, filled with flexible packing (such as graphite packing, PTFE packing) to prevent medium leakage from the valve stem gap and ensure flexible rotation of the valve stem.

Handwheel mechanism (optional): Some valves are equipped with manual mechanisms. When the pneumatic system fails, the valve can be manually operated through the handwheel to ensure fluid control under emergency conditions.

(2). Advantages of core structure design

High adjustment accuracy: The notch design of the V-shaped sphere results in an approximately linear relationship between the flow rate and the rotation angle of the sphere. Especially at small openings (0 to 30 degrees), the sensitivity of flow adjustment is much higher than that of ordinary ball valves, making it suitable for scenarios that require precise flow control, such as petrochemical and water treatment process adjustments.

Strong anti-blocking performance: The V-shaped incision generates a "shear force" when rotating, which can chop up fibers, particles and impurities in the medium, avoiding impurities from getting stuck between the ball and the valve seat, reducing valve jamming faults, and suitable for suspended solids or viscous media (such as sewage and pulp).

Reliable sealing: The soft seal valve seat is made of elastic material, with good adhesion and low leakage rate (up to ANSI Class VI). The hard sealed valve seat ensures fit through precision machining, can withstand high temperature, high pressure, and wear, and has a long service life.

Fast response speed: Pneumatic actuators have a simple driving method and a much faster action speed (usually 0.5 to 5 seconds) than electric actuators, making them suitable for working conditions that require quick cutting or adjustment.

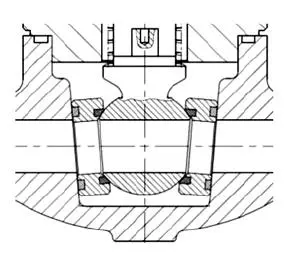

(3). Typical structural schematic diagram (simplified)

To sum up, the structural design of our pneumatic V-ball valve not only retains the characteristics of "compact structure and simple operation" of ordinary ball valves, but also strengthens the adjustment accuracy and anti-blocking ability through the combination of "V-adjustment+ cutoff control", making it the core equipment for "adjustment+ cutoff" in industrial fluid control.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeevalve.com/structural-analysis-of-pneumatic-v-shaped-ball-valves.html

.jpg)