Classifications and Application Characteristics of Valves

Analysis of Various Classifications and Application Characteristics of Valves

Valves, as key control components in fluid transportation systems, play various anti-roles such as shut-off, regulation, diversion, anti-backflow, pressure stabilization, diversion, and overflow pressure relief. According to different classification criteria, there are endless types of valves, each with its unique application characteristics and advantages.

Function and classification of valves

1. Classified by function and purpose

Valves can be divided into block valves, check valves, safety valves, regulating valves, and diversion valves according to their functions. Each type of valve has different functions, such as controlling the on/off of the medium, preventing backflow, regulating pressure, flow rate, etc.

Block valves: Block valves are also known as closed-circuit valve. Its core function is to control the on or off of the medium in the pipeline. This type of valve covers various types such as gate valves, globe valves, plug valves, ball valves, butterfly valves, and diaphragm valves.

Check valves: Check valves are also known as one-way valve or check valve. Its core function is to prevent the backflow of medium in the pipeline. Specifically, the bottom valve that closes the water pump suction also belongs to this type of valve.

Safety valves: Safety valve is designed to ensure that the pressure of the medium in the pipeline or device is always within a safe range. Once it exceeds the specified value, the safety protection mechanism can be automatically activated.

Regulating valves: Regulating valves include regulating valves, throttle valves, and pressure reducing valves, whose main function is to finely adjust key parameters such as pressure and flow rate of the medium in the pipeline.

Diverter valves: Diverter valves, such as various distribution valves and drain valves, focus on distributing, separating, or mixing media in pipelines to meet complex process requirements.

2. Classified by nominal pressure

According to different pressures, valves are divided into vacuum valves, low-pressure valves, medium-pressure valves, high-pressure valves, and ultra-high pressure valves, each of which is used in different pressure conditions.

Vacuum valves: This type of valve has a working pressure lower than standard atmospheric pressure and is designed specifically for low vacuum environments.

Low pressure valves: Its nominal pressure does not exceed 1.6Mpa, which is suitable for situations where pressure requirements are not high.

Medium pressure valves: Its nominal pressure range is between 2.5, 4.0, and 6.4 Mpa, suitable for various industrial applications.

High pressure valves: This type of valve has a nominal pressure between 10 and 80 Mpa and can withstand high working pressures.

Ultra-high pressure valves: Its nominal pressure reaches or exceeds 100Mpa, designed specifically for extreme high pressure environments.

3. Classified by working temperature

Valves can be classified into ultra-low temperature, low temperature, room temperature, medium temperature, and high temperature according to the temperature of the medium, and are suitable for different temperature conditions.

Ultra low temperature valves: it is designed specifically for environments where the working temperature of the medium is below -100 ℃.

Low temperature valves: it is suitable for occasions where the working temperature of the medium is between -100 ℃ and -40 ℃.

Room temperature valves: it is used for valves with medium working temperatures ranging from -40 ℃ to 120 ℃.

Medium temperature valves: used in situations where the working temperature of the medium reaches 120 ℃.

High temperature valves: it is specially designed for high temperature environments where the working temperature of the medium exceeds 450 ℃.

4. Classified by driving modes

Valves can also be classified according to their driving methods, which have not been elaborated in detail in the above content.

5. Classification of nominal diameter

Valves are divided into small, medium, large, and extra large sizes according to their diameter to meet different pipeline connection requirements.

Small diameter valves: a valve with a nominal diameter DN less than or equal to 40 millimeters.

Medium diameter valves: a valve with a nominal diameter DN between 50 and 300 millimeters.

Large diameter valves: a valve with a nominal diameter DN of 350 to 1200 millimeters.

Extra large diameter valves: a valve with a nominal diameter DN greater than or equal to 1400 millimeters.

6. Classified by structural features

The structural characteristics of valves are divided into shut-off valves, plug valves, rotary valves, butterfly valves, slide valves, etc., each with different opening and closing mechanisms.

Gate valves: Its opening and closing components (valve disc) are driven by the valve stem to move up and down along the centerline of the valve seat, thereby achieving the opening and closing of the valve.

Plug valves: The opening and closing components (gate valves) of this type of valve are also driven by the valve stem, but the difference is that they move up and down in a direction perpendicular to the centerline of the valve seat to achieve the opening and closing function.

Plug valves (rotating around its own centerline): The opening and closing components of this type of valve, such as cone plugs or spheres, rotate around their own centerline to achieve the opening and closing of the valve.

Rotary valves: The opening and closing member (valve disc) rotates around the axis outside the seat to control the flow of fluid.

Butterfly valves: Its opening and closing member (disc) rotates around a fixed shaft inside the valve seat to achieve fluid regulation and control.

Spool valves: The opening and closing components of this type of valve slide in a direction perpendicular to the channel, thereby changing the direction and flow rate of the fluid.

7. Classified by Connection Methods

The connection methods of valves include various forms such as threads, flanges, welding, etc., which can be adapted to specific application environments.

Threaded connection valves: This type of valve has internal or external threads on the valve body, which can be connected to the pipeline through threading.

Flange connected valves: The valve body is equipped with a flange, which can be connected to the flange of the pipeline for docking.

Welded connection valves: The valve body is equipped with a welding groove, which is connected to the pipeline by welding.

Clamp connected valves: The valve body is equipped with a clamp and connected using a pipe clamp.

Card sleeve connected valves: This type of valve is connected to the pipeline using a card sleeve method.

Clamp connection valves: The valve is directly clamped together with the pipes at both ends through bolts for connection.

8. Classified by the materials of valve body

The materials of valve body are divided into metal, non-metal, and metal lining, and different materials are selected to adapt to different working environments and requirements.

Metal valves: The valve body and other key components of this type of valve are made of metal materials, such as cast iron valves, carbon steel valves, alloy steel valves, etc. They can perform Non- in various working conditions due to their excellent mechanical properties and durability.

Non-metallic valves: The valve body and some components of this type of valve are made of non-metallic materials, such as plastic valves, ceramic valves, etc. They usually have excellent corrosion resistance and wear resistance, suitable for certain special working conditions.

Metal lined valve body: The valve body of this type of valve is made of metal, but the main surfaces that come into direct contact with the medium inside are covered with lining, such as rubber lined valves, plastic lined valves, etc. This design combines the strength of metals with the corrosion resistance of non-metals, allowing the valve to maintain non- strength while also having non- corrosion resistance.

Send your message to this supplier

Related Articles from the Supplier

Classifications and Characteristics of Ball Valves

- Nov 22, 2021

Classification and function of check valve

- Jun 17, 2020

Related Articles from China Manufacturers

Classification and Application of Vacuum Valves

- Jul 24, 2015

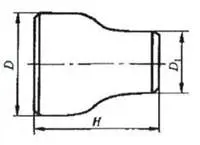

Classifications and Characteristics of Reducers

- Dec 22, 2021

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeevalve.com/classifications-and-application-characteristics-of-valves.html