Rolling Methods for Seamless Steel Tubes: Processes, Equipment, and Characteristics

1.3 Rolling Methods for Seamless Steel Tubes

1.3.1 Automatic Tube Mill

In an automatic tube mill line, the automatic mill functions as the primary rolling unit, supported by an elongator as an auxiliary mill, and a three-roll sizing mill to enhance the wall thickness accuracy and roundness of the hollow shell.

The basic process route of an automatic tube mill is as follows: billet surface inspection and cleaning → billet cutting and centering → billet heating → two-roll cross rolling and piercing → hollow shell rolling.

Automatic tube mills are classified by product size into small (140 mm), medium (250 mm), and large (400 mm) units. The rolling process begins with preparing a tube billet of a fixed length, followed by centering to ensure stable bite-in and prevent uneven wall thickness. The heated billet is then pierced, and the hollow shell is rolled, elongated, and sized. The rolling process typically requires two to three passes, with the billet usually rotated 90° between the first and second passes to ensure roundness. Automatic tube mills are widely employed in manufacturing seamless tube because of their versatility and high efficiency. Billet heating must achieve the appropriate rolling temperature. Suitable furnaces include inclined-bottom continuous furnaces, walking-beam furnaces, sectional rapid-heating furnaces, and ring furnaces, all of which enhance heating efficiency.

1.3.2 Continuous Tube Mill

The world’s first continuous tube mill for rolling cast billets was introduced in 1843. Initially, its use was limited by short tube lengths, low product quality, and a narrow range of available sizes. After subsequent improvements, continuous tube mills became the dominant technology for producing small-diameter seamless tubes. Their advantages include high product quality, efficient production of small-diameter tubes, and a wide range of available sizes. Limitations include the complexity of producing long mandrels and the high cost of equipment. In continuous rolling, a mandrel is inserted into a preheated hollow shell, which is then rolled under lubricated conditions.

The general process sequence is: billet heating → piercing → continuous rolling → shell reheating → sizing or reduction in a sizing mill → cooling on a cooling bed → straightening, end cutting, and finishing.

Since 1976, research and development in China has laid the foundation for the large-scale domestic deployment of continuous mills. Continuous mills are distinguished by high rolling speeds and the production of long hollow shells. Key steps include billet heating, hot centering, piercing, elongation rolling, reduction, mandrel extraction, cooling, and finishing. Continuous tube mills are categorized by mandrel movement into fully floating mandrel mills, semi-floating mandrel mills, and fixed (or limited) mandrel mills. Based on their layout, they are classified as straight cross-shift, zigzag, and trapezoidal reciprocating arrangements.

(1) Fully Floating Mandrel Mill

In first-generation continuous mills, the mandrel moves freely with the shell, forming a fully floating mandrel system. In this setup, the mandrel is inserted into the pierced shell, and both are rolled together as a single unit.

Because the mandrel is unconstrained, instability during biting-in and ejection can lead to variations in wall thickness. After rolling, the mandrel is removed using a mandrel extractor and recycled, typically in sets of 12. Process characteristics: Billets are heated in a ring furnace, pierced using a Diescher piercer, and then elongated in a six-stand, three-roll elongator to form a hollow shell. The shell is then placed on a floating mandrel and continuously rolled through a multi-stand mill—typically eight stands—with each roll pass rotated 90° relative to the previous one. Wall thickness is regulated by the mandrel diameter, while lubrication is applied to reduce friction, extend mandrel life, and enhance the quality of the inner surface.

(2) Semi-Floating Mandrel Mill

In this configuration, the mandrel is inserted into the pierced shell, with its tail secured to a restraining device, allowing it to advance at a controlled speed. During the initial passes, the mandrel moves faster than the shell; In later passes, the mandrel moves slower than the shell. Before extraction, the restraining device releases the mandrel, which is then withdrawn by the extractor for reuse. Semi-floating mandrels provide greater wall thickness accuracy than fully floating mandrels, though they are less precise than limited mandrel mills. The restraining system is more complex than that of fully floating mandrels but simpler than that of limited mandrels. Near the end of rolling, the mandrel accelerates to facilitate extraction.

(3) Limited Mandrel Mill

In a limited mandrel mill, the mandrel is fixed at the tail end and advances at a controlled speed, which can be adjusted according to the product size. After rolling, the mandrel is retracted by the restraint system, eliminating the need for a separate extraction step. This method provides the highest wall thickness accuracy and dimensional precision, making it the dominant process in seamless tube production today. Compared with floating and semi-floating mandrels, it offers greater stability and eliminates the need for mandrel extraction during rolling; however, it incurs higher costs, and mandrel wear during retraction can reduce service life.

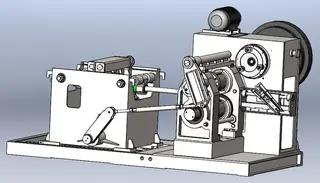

1.3.3 Pilger Mill

Developed in the 1950s, the pilger mill (shown in Fig. 1.1) can produce tubes with outside diameters ranging from 20 to 760 mm and wall thicknesses of 4 to 100 mm, using either forged round billets or continuously cast billets. In this process, a two-roll mill rotates counter to the tube’s movement. Pilger mills are capable of producing both round and shaped cross-sections. The roll pass profile continuously changes, affecting both rolling efficiency and product quality. The rolling process proceeds as follows: biting in from section A–B, finishing in section B–C, and gradual release in section C–D. Full-length rolling is employed to minimize material losses at the tube ends, reduce production costs, and enhance overall efficiency.

1.3.4 Assel Mill

The first Assel mill was introduced in 1935, designed to produce thick-walled tubes with high precision and excellent surface quality, primarily for use in bearings and mechanical components. The Assel mill is a mandrel-based skew-rolling system comprising a rotating frame and a fixed frame. As the rotating frame turns relative to the fixed frame, the roll axes are inclined to the rolling centerline, causing the tube shell to advance in a helical motion. The rolling process begins with a small feed angle at the roll bite and proceeds through a compression zone, where both the wall thickness and the outer diameter of the tube are gradually reduced. Downstream, the sizing zone refines the inner and outer surfaces while slightly expanding the tube, which aids in the smooth extraction of the mandrel. Assel mills can produce tubes up to 240 mm in diameter with a diameter-to-thickness ratio below 12, achieving ±0.5% outer diameter tolerance and 5–7.5% wall thickness tolerance, along with an excellent surface finish. However, thin-walled tubes may develop “triangular ends.” To address this, the improved Transval mill was developed, extending the diameter-to-thickness ratio up to 35, allowing for thin-walled tube production with increased capacity.

1.3.5 Diescher Mill

The Diescher mill, developed from the automatic mill, is a mandrel-based skew-rolling elongator. It employs upper and lower guide discs along with two horizontally arranged rolls. Rolling is carried out by passing the hollow billet, fitted with a mandrel, through the rolls and guide disc system. Diescher mills produce tubes with excellent surface quality and a broad range of wall thicknesses; however, their relatively low efficiency has limited broader adoption. Derived from the Diescher piercer, these mills utilize long mandrels. Small mills typically employ floating mandrels to shorten production cycles, whereas medium-sized mills use limited mandrels to reduce mandrel length and lower costs.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Rolling Shutter Lock-Let Security Accompany You

- Mar 07, 2017

The Rolling Process of the Valve Stem

- Oct 26, 2022

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeepipe.com/rolling-methods-for-seamless-steel-tubes-processes-equipment-and-characteristics.html