Corrosion Effects and Protection Strategies for Offshore Oil and Gas Pipelines

Abstract: Corrosion in offshore oil and gas pipelines is directly influenced by the marine environment and the effectiveness of corrosion protection measures. Key factors contributing to offshore pipeline corrosion include seawater salinity, ocean currents, oil and gas composition, and internal chemical reactions. Corrosion can lead to critical failures such as pipeline leaks, resulting in significant economic losses and environmental harm. This study examines corrosion-induced stress failures in a specific offshore oil and gas pipes, evaluates corrosion progression using early-warning systems, and proposes timely anti-corrosion measures to mitigate further deterioration. These strategies reduce oil and gas corrosiveness while preserving the structural integrity and operational reliability of offshore oil and gas pipeline systems.

Introduction

Offshore oil and gas transportation systems primarily depend on subsea pipelines, which play a vital role in ensuring stable, efficient, and continuous energy delivery. These pipelines offer several advantages, including high transport capacity, cost-effectiveness, operational flexibility, and enhanced safety. However, the high salinity and dynamic flow conditions of seawater significantly accelerate pipeline corrosion, increasing the risk of structural degradation over time. Subsea pipelines operating in harsh marine environments are especially susceptible to corrosion-related failures. To address this issue, continuous monitoring, proactive maintenance, and the integration of advanced corrosion protection technologies are essential. These measures help ensure the long-term integrity, safety, and operational reliability of offshore oil and gas infrastructure, while minimizing environmental impact and economic losses.

1. Factors Contributing to Corrosion of Offshore Oil and Gas Pipelines

1.1 Seawater Characteristics

The high salinity and electrical conductivity of seawater significantly accelerate corrosion in offshore oil and gas pipelines. Dissolved salts and ions act as electrolytes, creating a highly conductive marine environment that promotes electrochemical reactions and accelerates metal degradation. Regions with elevated salinity and aggressive seawater chemistry exhibit significantly higher corrosion rates. Variations in seawater composition across different marine environments directly impact the severity of pipeline corrosion. Therefore, conducting regional water quality assessments is critical during offshore pipeline design and material selection to ensure long-term durability and structural integrity.

1.2 Seawater Flow

The dynamic movement of seawater significantly accelerates corrosion in subsea pipelines. Constant water flow increases the scouring and erosion of pipeline surfaces, gradually stripping away protective coatings and promoting the rapid dissolution of passive film layers—leading to faster material degradation and increased maintenance needs. High seawater flow velocities amplify corrosion currents, accelerating material degradation and reducing pipeline lifespan. To mitigate these effects, it is essential to incorporate seawater hydrodynamics into the early design and planning phases of offshore pipeline projects. Implementing targeted solutions—such as abrasion-resistant coatings and optimized pipeline routing—can significantly mitigate the effects of seawater flow, reduce mechanical wear, and extend offshore pipeline service life.

1.3 Oil and Gas Composition

Offshore oil and gas often contain corrosive components such as carbon dioxide (CO₂), hydrogen sulfide (H₂S), chloride ions (Cl⁻), and water (H₂O), all of which contribute significantly to internal pipeline corrosion. When combined with high temperatures, high pressure, and multiphase flow conditions, these corrosive compounds significantly accelerate internal pipeline corrosion and increase the risk of structural failure. Among these, CO₂-induced corrosion poses one of the greatest threats to subsea pipeline integrity. When carbon dioxide reacts with water, it forms carbonic acid, which aggressively attacks the internal surface of the pipeline—especially in the presence of other corrosive agents such as H₂S or chloride ions. This type of corrosion appears in multiple forms, including uniform corrosion, localized corrosion, pitting, and honeycomb-like degradation. Subsea pipelines are especially vulnerable to localized corrosion, which is difficult to predict and can result in sudden, catastrophic failure.

1.4 Internal Corrosion Mechanisms

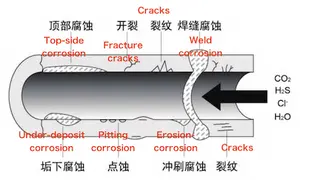

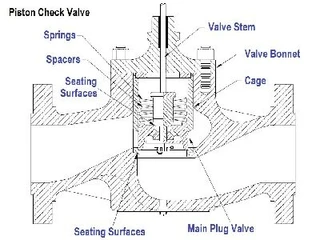

Corrosion-related failures are responsible for approximately 37% of all offshore pipeline incidents, underscoring the critical need to understand internal corrosion mechanisms and implement effective mitigation strategies. Key contributors to internal corrosion include wall thinning, weld seam corrosion, erosion-corrosion, crack propagation, and stress corrosion cracking (SCC), as illustrated in Figure 1: Pipeline Corrosion Mechanism. These failure modes are strongly influenced by material composition, welding procedures, weld defects, residual stresses, and the structural integrity of the pipeline. Effective corrosion risk management involves thoroughly evaluating these internal mechanisms to inform material selection, welding standards, and inspection protocols, as illustrated in Figure 1: Pipeline Corrosion Mechanism.

Figure 1 Pipeline corrosion mechanism

2. Analysis of the Impact of Corrosion on Pipelines

2.1 Corrosion Impact Evaluation Methods for Pipelines

2.1.1 Residual Strength Assessment Techniques

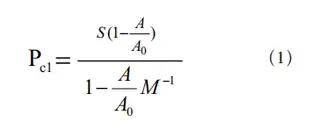

Residual strength assessment plays a crucial role in determining the failure pressure of corroded pipeline sections, especially in offshore oil and gas operations. This assessment provides valuable insight into the extent of corrosion damage and aids in evaluating the structural integrity of the pipeline. The failure pressure P0P_0P0 of a pipeline affected by corrosion can be estimated using the following equation:

where:

P0 = failure pressure of the corroded pipeline section

S = allowable stress of the pipeline material

A0 = cross-sectional area lost due to corrosion

A = original cross-sectional area of the pipeline

where d is the corrosion depth (mm).

By calculating the changes in hoop stress caused by wall thickness loss, this method estimates the failure pressure after corrosion damage. This provides critical guidance for making maintenance or replacement decisions.

2.1.2 Failure Probability Analysis

Failure probability analysis assesses the likelihood of pipeline rupture or leakage by considering factors such as corrosion defect depth and operating pressure. According to national standards, when the corrosion depth exceeds 80% of the pipeline wall thickness, the risk of failure increases significantly. This method applies reliability theory to assess corrosion risk. When the operating pressure p approaches the critical failure pressure P0, the pipeline is considered to be in a high-risk zone. Using Monte Carlo simulations, key random variables—such as outer diameter, wall thickness, and defect depth—are sampled to estimate the failure probability Pf.

In the simulation process:

Let F be the total number of simulation cycles.

Let n be the number of times the failure condition Z<0 occurs.

Then, the failure probability Pf is calculated as:

According to reliability theory, the relationship between failure probability and reliability R is:

where:

Pf is the probability of failure.

R is the reliability of the pipeline performance.

As reliability decreases, the operational risk of the pipeline correspondingly increases. Therefore, timely operation and maintenance (O&M) measures must be implemented once the failure probability exceeds acceptable thresholds. Based on API 579 guidelines, pipelines are classified into different risk levels according to their failure probability and condition. An example of this classification is shown below:

Table 1. Pipeline Reliability Risk Levels and Early Warning Indicators

|

Design Target |

Failure Probability |

Risk Level |

Warning Level |

Warning Color |

|

0.98 |

0.02 |

Low |

None |

Purple |

|

0.96 |

0.04 |

Lower |

Low |

Green |

|

0.94 |

0.06 |

Medium |

Medium |

Yellow |

|

0.92 |

0.08 |

Medium-High |

Severe |

Red |

|

0.90 |

0.10 |

High |

Critical |

Black-Blue |

2.2 Pipeline Corrosion Failure Analysis

To evaluate the performance of offshore oil and gas pipelines under corrosion-induced failure conditions, it is essential to identify key geometric and damage parameters. The pipeline has an average inner diameter (D) of 200 mm, an average wall thickness (B) of 14 mm, an average corrosion defect side length (L) of 25 mm, and an average corrosion depth (d) of 3.15 mm. These values serve as the foundation for evaluating the structural integrity and failure risk of the corroded pipeline section.

2.2.1 Corrosion Failure Pressure Analysis

Residual strength evaluation techniques are used to calculate the failure pressure (PPP) of corroded pipelines. The corrosion failure stress values for the four pipeline samples range from 32.12 MPa to 32.56 MPa, as summarized in Table 2. These results offer crucial insights into the pressure-bearing capacity of the pipeline after corrosion damage and serve as an important reference for maintenance and replacement decisions.

Table 2. Pipeline Reliability Risk Classification and Warning Levels

|

Target Reliability |

Failure Probability |

Risk Level |

Warning Level |

Warning Color |

|

0.98 |

0.02 |

Low |

No Warning |

Purple |

|

0.96 |

0.04 |

Slightly Low |

Low Warning |

Green |

|

0.94 |

0.06 |

Moderate |

Medium Warning |

Yellow |

|

0.92 |

0.08 |

Moderately High |

Severe Warning |

Red |

|

0.90 |

0.10 |

High |

Critical (Extreme Risk) |

Black and Blue |

2.2.2 Failure Probability Analysis

Using the pipeline corrosion risk grading method detailed in Table 1, an online simulation tool was employed to assess the failure probability. The simulation parameters included an initial design life of 20 years and an actual service period of 55 years, with simulations performed in 10-year intervals. The software utilized a residual strength evaluation model to predict the pipeline failure probability over time. The analysis results are summarized in Table 3.

Years 8.1–10.3:

Minor corrosion occurs in localized areas of the pipe wall, causing a gradual reduction in wall thickness. At this stage, the pipeline’s performance risk remains low, with no expected leakage. Preventive anti-corrosion measures should be strengthened to control further deterioration.

Years 10.3–11.6:

Corrosion accelerates across multiple pipeline sections, potentially causing unpredictable defects. The risk level is classified as “low,” requiring more frequent inspections and increased anti-corrosion treatment cycles.

Years 11.6–13.2:

Corrosion depth increases significantly, leading to further reduction in wall thickness. At this stage, the risk of leakage arises, necessitating close monitoring by the pipeline management team and implementation of targeted mitigation measures.

Years 13.2–14.4:

Corrosion-induced leakage points start to develop. Real-time monitoring becomes essential, and decompression measures should be implemented to reduce operating stress on the affected pipeline sections.

Beyond 14.4 years:

Beyond 14.4 years, the corrosion depth surpasses critical thresholds, severely compromising the pipeline’s structural integrity. At this stage, the pipeline no longer meets operational standards and must be replaced immediately to prevent catastrophic failure.

3. Effective Methods for Preventing and Controlling Corrosion in Offshore Oil and Gas Pipelines

3.1 Pipeline Surface Corrosion Protection

3.1.1 PE Anti-Corrosion Coating

Table 3: Pipeline Failure Analysis (Unit: Years)

|

Target Safety Level |

0.02 |

0.04 |

0.06 |

0.08 |

0.10 |

|

Pipeline Service Life |

8.1–10.3 |

10.3–11.6 |

11.6–13.2 |

13.2–14.4 |

≥14.4 |

|

Risk Level |

Low |

Low |

Intermediate |

Medium-High |

Advanced |

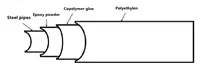

Polyethylene (PE) anti-corrosion coatings provide superior corrosion protection for offshore oil and gas pipelines. With low water absorption, high mechanical strength, and exceptional resistance to aggressive marine environments, PE coatings are widely used to enhance pipeline durability and service life. By minimizing steel degradation caused by saltwater and harsh marine conditions, the anti-corrosion layer plays a crucial role in preserving the long-term integrity and performance of offshore oil and gas pipelines. Different projects may require different coating thicknesses depending on environmental corrosion factors. Therefore, the coating specifications must be tailored to the pipeline's specific corrosion risk.

Surface Preparation – Step 1: Sandblasting

Before applying the coating, the external surface of the pipeline must undergo sandblasting to remove any contaminants. The pipe surface must be free from oil, salt, rust, or other pollutants, as these can reduce coating adhesion and compromise corrosion protection. If salt deposits are detected on the pipeline surface, it should be thoroughly rinsed with freshwater and then heated to a temperature between 40°C and 70°C. This process ensures a clean, dry substrate, which is essential for proper coating adhesion and long-term corrosion protection.

After sandblasting, the surface cleanliness and profile should be inspected according to SSPC-SP10 (Near-White Metal Blast Cleaning) standards to ensure proper surface preparation and coating performance.

Coating Process – Step 2: PE Coating Application

Before initiating the polyethylene (PE) anti-corrosion coating process, the coating contractor is required to submit a detailed application procedure for review and approval by the project owner. This ensures that all coating activities comply with project specifications and industry standards. The polyethylene (PE) coating should be applied using a dedicated, automated production line designed for continuous operation. This ensures uniform coating thickness, consistent quality, and long-term performance across all pipeline sections.

The polyethylene (PE) anti-corrosion coating system typically consists of three primary layers:

Epoxy primer – Provides strong adhesion to the steel substrate and serves as the corrosion-resistant base layer.

Adhesive layer – Bonds the epoxy primer to the outer polyethylene layer, ensuring structural integrity.

Polyethylene (PE) topcoat – Offers excellent mechanical strength and chemical resistance, protecting the pipeline from external damage and environmental degradation.

The coating application process must strictly adhere to the manufacturer’s specifications. Additionally, a 100 mm uncoated section should be reserved at both ends of each pipe to ensure optimal welding quality and seamless pipeline installation.

3.1.2 Advanced Powder Coating Technology

Next-generation powder anti-corrosion coatings are widely applied in subsea pipeline insulation because of their superior corrosion resistance, environmental sustainability, and straightforward application process. These coatings provide excellent resistance to external mechanical impacts while ensuring zero environmental pollution during the application process. For optimal performance, the recommended coating thickness ranges from 0.4 mm to 0.5 mm. Applying this technology requires a specialized production line designed to handle powder coating materials according to the manufacturer’s specifications. This setup ensures proper material selection and consistent, high-quality coatings. During the anti-corrosion process, a 100 mm uncoated section must be maintained at both ends of the steel pipe to facilitate field welding operations and ensure proper joint integrity.

3.1.3 External Anti-Corrosion Protection for Risers

Risers demand stringent anti-corrosion measures due to their constant exposure to harsh marine environments. The coating applied must deliver excellent impact resistance, abrasion resistance, and durable corrosion protection to ensure long-term operational reliability.

Risers are typically exposed to three distinct environmental zones:

Fully Submerged Zone – Continuously underwater, experiencing constant hydrostatic pressure and corrosion challenges.

Splash Zone – Subject to intermittent wetting and drying due to waves and tides, resulting in fluctuating corrosion risks.

Atmospheric Zone – Exposed to air, rain, and wind, facing weathering and atmospheric corrosion.

For risers located in the fully submerged and atmospheric zones, polyethylene (PE) anti-corrosion coatings are commonly applied because of their excellent durability and proven effectiveness in harsh marine environments. In the splash zone, characterized by frequent wave impact and fluctuating moisture levels, enhanced protective coatings are necessary. In non-icy marine environments, chloroprene rubber coatings are ideal due to their excellent flexibility and superior resistance to water impact. In icy or freezing conditions, a combination of protective materials—such as heat-shrinkable tapes and chloroprene rubber coatings—is recommended to improve coating performance and extend the service life of risers.

3.1.4 External Anti-Corrosion Treatment for Pipeline Joints and Contact Points

Proper external anti-corrosion treatment of pipeline joints and contact points is crucial for maintaining the long-term integrity of offshore oil and gas pipelines. Before applying patching or repair coatings, these areas must undergo thorough surface preparation and cleaning to ensure effective adhesion and corrosion protection. This process involves removing rust, eliminating surface contaminants, and thoroughly cleaning all connection points. Any residual debris or impurities can significantly reduce the effectiveness and durability of the anti-corrosion coating. Once cleaned, the contact surfaces should be inspected following SSPC-SP10 (Near-White Metal Blast Cleaning) standards to verify surface cleanliness and preparation quality.

Key Processes for Joint Coating:

Process 1 – Pre-treatment Inspection:

Before applying heat shrink tape, carefully inspect its external surface for cracks, bubbles, or any irregularities. Pay close attention to the base adhesive layer to ensure it is free from foreign inclusions or contaminants. Early detection and remediation of such defects help prevent coating failure and significantly extend the pipeline’s service life.

Process 2 – Post-treatment Inspection:

After applying the heat shrink tape, conduct a thorough visual inspection to identify pinholes, voids, or areas with weak adhesion. Pay particular attention to the tape edges to ensure complete bonding with the pipe surface, which is critical for long-term corrosion protection. The overlap at each tape edge should not exceed 10 mm of displacement, and the overlap between the heat shrink tape and the original coating must be at least 50 mm, according to standard requirements. Additionally, ensure the patch is firmly adhered, and carefully inspect for any small pinholes that could cause long-term coating degradation.

3.2 Internal Anti-Corrosion Methods for Pipelines

Method 1: Use of Carbon Steel with Corrosion Inhibitors

A widely adopted approach for internal corrosion protection combines carbon steel with corrosion inhibitors. Carbon steel is preferred for its low cost, excellent ductility, and cost-effectiveness, making it an economical choice for pipeline construction. Corrosion inhibitors create a protective molecular film on the internal surface of the pipe, effectively isolating the transported medium from the steel and significantly reducing corrosion rates. This method is particularly effective when combined with real-time corrosion monitoring technologies, enabling operators to detect early-stage corrosion and implement timely maintenance or repair interventions.

Method 2: Removal of Corrosive Components

In oil and gas fields with high carbon dioxide (CO₂) concentrations, internal pipeline corrosion accelerates due to CO₂ reacting with water to form corrosive agents. Deploying dehumidifiers effectively separates moisture and CO₂, thereby reducing corrosion activity and extending pipeline service life. Additionally, selecting high-alloy materials for pipeline manufacturing can significantly extend service life by providing enhanced corrosion resistance. These materials help slow corrosion rates, thereby improving the durability and operational reliability of the entire pipeline system.

4. Conclusion

In offshore oilfield corrosion prevention and control, advanced methods such as residual strength analysis and Monte Carlo simulation are widely used to comprehensively evaluate pipeline corrosion damage and failure risk. These methods enable engineers to accurately assess pipeline performance risks and implement timely, targeted anti-corrosion measures. Due to the highly corrosive marine environment, the service life of offshore oil and gas pipelines is often limited, making effective corrosion protection a critical priority for ensuring pipeline reliability. As the pipeline’s service life nears the predefined safety limit, the risk of problems such as leaks and failures increases significantly. To address this, offshore oil and gas operations and maintenance teams should establish safety-critical time thresholds to serve as early warning indicators. This approach enables proactive pipeline monitoring, improved corrosion management, and extended pipeline service life, ultimately enhancing the reliability and safety of offshore oil and gas transportation systems.

Send your message to this supplier

Related Articles from the Supplier

The Scouring of Oil and Gas Pipelines

- Apr 26, 2023

Corrosion Protection Methods of Gas Pipelines

- Jul 12, 2021

Installation guide of oil and gas pipeline

- Nov 19, 2018

Types and Characteristics of Outdoor Gas Pipelines

- Mar 23, 2021

Kashagan Oil, Gas Pipelines Need Replacement

- Apr 29, 2014

Cleaning Offshore Pipelines

- Feb 05, 2024

China Oil and Gas Pipeline Expo, July 29-31, 2014

- Jul 10, 2014

Related Articles from China Manufacturers

Related Products Mentioned in the Article

XIAMEN LANDEE INDUSTRIES CO., LTD.

- https://www.landee.cn/

- Address: NO. 321 JIAHE ROAD, XIAMEN, P.R.CHINA 361012

- Phone: 86-592-5204188

- Business Type: Trading, Manufacturer,

Supplier Website

Source: https://www.landeepipe.com/corrosion-effects-and-protection-strategies-for-offshore-oil-and-gas-pipelines.html

.jpg)