Installation and Maintenance of Fully Welded Ball Valves

In industrial and construction fields, valves are indispensable components of piping systems. They are responsible for controlling fluid flow and ensuring the normal operation of the system. Fully welded ball valves, as an efficient and reliable valve type, are widely used in various applications due to their unique design and outstanding performance. However, correct installation and proper maintenance are the keys to ensuring the long-term, stable operation of fully welded ball valves. This article provides a detailed introduction to the installation requirements, maintenance methods, and common precautions for fully welded ball valves, helping you better understand and operate the fully welded ball valve.

Overview of Fully Welded Ball Valves

A fully welded ball valve is a type of ball valve in which the valve body and bonnet are connected by welding. This design not only enhances the strength and sealing performance of the valve but also significantly reduces the risk of external leakage. Compared with traditional threaded or flanged valves, fully welded ball valves offer higher reliability and a longer service life.

In addition, the ball and stem of fully welded ball valves are typically made of stainless steel, while the valve seat is made of reinforced PTFE. The use of these materials allows the valve to operate stably over a wide temperature range (–60°C to 200°C) and provides excellent corrosion resistance.

1. Advantages of Fully Welded Ball Valves

- High Strength and Tight Sealing: The welded structure ensures a stronger connection between the valve body and bonnet, greatly reducing the possibility of leakage.

- Excellent Corrosion Resistance: The use of stainless steel and PTFE materials enables long-term operation in harsh environments.

- Lightweight Design: The welded steel-pipe valve body structure reduces overall weight, making installation and maintenance easier.

- Long Service Life: The ball seat is made of reinforced PTFE with excellent sealing performance. Both the ball and stem are made of stainless steel, and the stem features a blowout-proof design with double O-ring anti-ejection construction, ensuring tight sealing and long-term durability.

- Maintenance-Free Design: Direct-buried fully welded ball valves adopt a special structure that allows maintenance-free operation. Before burial, a special anti-corrosion coating is applied to the valve exterior. Three extended lines, for emergency grease injection to the seat and stem, cavity venting, and stem extension, are lengthened according to burial depth, allowing all operations to be performed at ground level.

2. Application of Fully Welded Ball Valves

Fully welded ball valves are widely used in construction, fire protection, oil and gas, chemical, and other industries. In particular, direct-buried fully welded ball valves are an ideal solution in construction and fire protection systems due to their maintenance-free design and high-pressure capability. These valves can operate stably under high pressure but require strict installation techniques and careful handling during use.

Installation Requirements for Fully Welded Ball Valves

Only with correct installation can the full performance of fully welded ball valves be realized, ensuring the stable operation of the piping system. The following installation requirements are not only the foundation for proper valve operation but also an important prerequisite for the safe and efficient operation of the entire pipeline system.

1. Installation Direction

In principle, fully welded ball valves are non-directional. However, in practical applications, to prevent excessive leakage at the joint between the valve body and bonnet, the valve body is usually installed facing the direction of incoming media. This installation method effectively reduces fluid impact on the body–bonnet joint and improves sealing performance.

2. Pre-Installation Inspection

Before installing a fully welded ball valve, a series of inspections must be carried out to ensure valve quality and suitability:

- Size and Type Matching: Ensure that the valve size and type match the piping system and confirm the installation position of both the valve and pipeline.

- Visual Inspection: Check the valve body and bonnet for damage and ensure there are no foreign objects inside the valve. Special attention should be paid to sealing components such as O-rings and packing, as their integrity is critical to preventing media leakage.

- Functional Inspection: Check the operating flexibility of the valve to ensure smooth opening and closing without jamming or air leakage. Inspect the actuator for smooth operation, verify that bolts and nuts are secure, and ensure the packing is properly compressed.

3. Pressure Testing

Fully welded ball valves must undergo pressure testing before installation to verify their tightness. This step is critical, as only valves that pass pressure testing can ensure reliability in actual service. Pressure testing typically includes strength testing and sealing testing to confirm valve performance under high-pressure conditions.

4. Lifting Method

Proper lifting is an important part of the installation process. To protect the valve stem, lifting chains must not be attached to the handwheel, gearbox, or actuator. Correct lifting methods prevent damage to valve components and ensure safety during handling. Soft slings should be used to avoid impact or collision, and protective measures should be applied to valve edges.

5. Welding Specifications

For direct-buried fully welded ball valves, welding is usually used to connect the valve to the main pipeline. Weld quality must meet relevant standards, as it directly affects valve sealing and strength.

Specific requirements include:

- Surface Cleaning: Before welding, clean the pipeline and valve weld ends to remove dust, oil, and other contaminants.

- Valve Position: The valve must be in the fully open position during welding to prevent welding slag from entering the valve.

- Protective Measures: Before welding, cover the valve sealing area with protective tape to prevent spatter from entering.

- Welding Procedure: Follow the appropriate welding procedure specifications, selecting suitable welding methods and parameters. For large-diameter valves, segmented welding in a specified sequence is required to ensure weld quality and strength.

- Cooling and Inspection: After welding, allow the valve to cool completely before operating it.

Detailed Procedure of Fully Welded Ball Valve Installation

Next, we will take an in-depth look at the detailed installation procedures for fully welded ball valves. Through clear workflows and key operational points, this section will help you gain a solid understanding of how to install fully welded ball valves correctly, ensuring high efficiency and reliability in actual applications.

1. Preparation

Ensure the pipeline interior is clean and free of debris or rust to prevent foreign matter from entering the valve.

Check pipeline dimensions and geometric tolerances to ensure compatibility with the valve connections.

Prepare installation tools such as welding equipment and lifting devices.

2. Lifting the Valve

Attach lifting slings to the lifting lugs (rings) or flanges on the valve body, not to the handwheel, stem, or actuator.

Use soft slings to avoid impact or collision, and protect valve edges as necessary.

3. Valve Inspection

Confirm the valve position, which should generally be fully open.

Check that the valve cavity and sealing surfaces are clean; remove any contaminants with a soft cloth.

Inspect the actuator for smooth operation and ensure all bolts, nuts, and packing are properly secured.

4. Welding Connection

Clean the welding surfaces of both the pipeline and valve.

Keep the valve fully open during welding to prevent slag intrusion.

Cover sealing areas with protective tape before welding.

Perform welding according to the specified welding procedures and parameters.

After welding, allow the valve to cool completely before operation.

5. Post-Installation Inspection

Inspect weld seams for defects such as incomplete fusion, cracks, or porosity.

Perform sealing tests to ensure there is no leakage.

Conduct operational tests to confirm smooth and unobstructed valve operation.

Maintenance and Care of Fully Welded Ball Valves

Although fully welded ball valves are known for their durability and reliability, long-term operation and complex working conditions may still affect their performance. Proper maintenance and care can extend service life while ensuring safe and stable operation.

1. Routine Inspection

- Operational Flexibility: Regularly check valve operation to ensure smooth opening and closing without jamming or leakage.

- Sealing Component Inspection: Inspect sealing components such as O-rings and packing. Aging or damage may cause leakage and should be addressed promptly.

- Valve Body Inspection: Check the valve body and bonnet for damage, especially weld areas for cracks or corrosion.

2. Cleaning and Lubrication

- Surface Cleaning: Regularly remove dirt from the valve surface to reduce corrosion.

- Ball Movement: Periodically operate the valve to prevent malfunction caused by prolonged inactivity.

- Seat Cleaning: Clean valve seats regularly to prevent dirt accumulation and loss of flexibility.

- Grease Injection: Valves on auxiliary gas mains are often rarely operated. They should be opened and closed at least once a year and injected with an appropriate amount of grease to prevent bonding between the ball and seat and reduce wear.

3. Maintenance of Special Structures

Direct-buried fully welded ball valves feature a special maintenance-free design:

- Anti-Corrosion Coating: Before burial, apply a special anti-corrosion coating to protect the valve from soil moisture and chemicals.

- Extended Components: Extend the grease injection lines for the valve seat and stem, the cavity vent line, and the stem itself according to burial depth, allowing all operations to be carried out at ground level.

- Valve Pit Construction: After direct burial, only a small valve access pit is required. Conventional non–fully welded ball valves cannot be buried directly and require large valve chambers, increasing construction difficulty and creating potentially hazardous confined spaces.

Conclusion

Fully welded ball valves are widely used in industrial and construction applications due to their high efficiency and reliability. Correct installation and proper maintenance are essential to ensuring their long-term stable operation. During installation, attention must be paid to installation direction, pre-installation inspection, pressure testing, lifting methods, and welding specifications. During operation, routine inspection, cleaning and lubrication, and maintenance of special structural features are critical to maintaining performance. Through this article, it is hoped that you now have a deeper understanding of the installation and maintenance of fully welded ball valves. Proper installation and maintenance not only improve system safety but also extend valve service life, reduce maintenance costs, and ensure efficient system operation.

Send your message to this supplier

Related Articles from the Supplier

Installation and Maintenance of Electric Ball Valves

- Dec 14, 2024

Features and Installation of V-type ball valve

- Dec 14, 2024

Installation of welded ball valve

- Dec 14, 2024

Installation Considerations for Safety Valves

- Feb 08, 2025

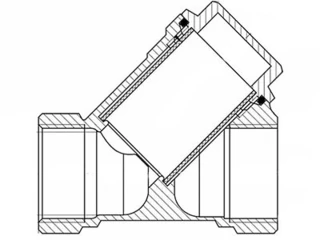

Complete Installation Guide for Y-Type Strainers

- Nov 06, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Address: Dongou Industrial Zone, Oubei, Wenzhou, Zhejiang, China

- Phone: 86 577 5798 7171

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/installation-and-maintenance-of-fully-welded-ball-valves.html