Comparison Between Slab Gate Valves and Knife Gate Valves

In the industrial field, valves are indispensable components of pipeline systems. They undertake the critical task of controlling fluid flow and ensuring the safe operation of systems. Among them, slab gate valves and knife gate valves, as two important types, play a vital role in many industrial scenarios with their unique advantages and wide applications. This article will take an in-depth look at the features, working principles, application scenarios, and differences between knife gate valves and slab gate valves, helping you better understand and select the right gate valve products.

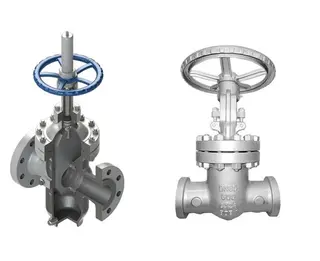

Slab Gate Valves: Efficient Sealing and Reliable Performance

Among many industrial valves, slab gate valves stand out with their excellent sealing performance and reliable operation, becoming the preferred choice for many industrial pipeline systems. The design concept of this valve aims to provide efficient, reliable sealing while ensuring simple and safe operation. Next, we will discuss in detail the structure, working principle, application scenarios, and unique advantages of slab gate valves.

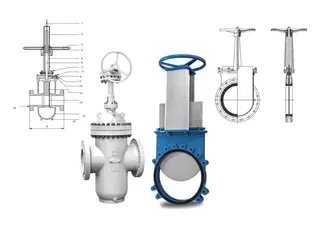

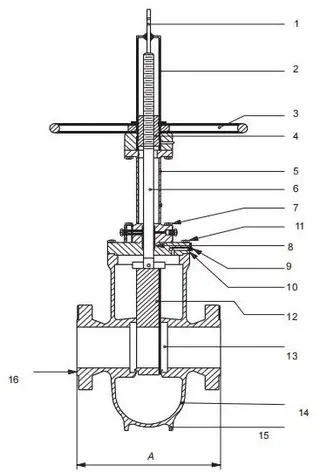

1. Structure and Working Principle of Slab Gate Valves

The slab gate valve is a sliding valve in which the closure member is a parallel gate. The closure member can be a single gate or a double gate equipped with a spreading mechanism. The sealing force of the gate against the valve seat is controlled by the medium pressure acting on the floating gate or floating seat. In the case of a double-gate slab valve, the spreading mechanism between the two gates supplements this sealing force. This unique structural design allows the slab gate valve to achieve bidirectional sealing when closed, ensuring sealing performance at both the inlet and outlet.

The valve seat adopts a floating seat structure with O-ring sealing and preload. This design not only improves sealing performance but also reduces the operating torque to only half that of ordinary valves, greatly lowering operating difficulty and enabling easy opening and closing. In the fully open position, the passage of the slab gate valve is a straight line with a very low flow resistance coefficient, resulting in almost no pressure loss. This makes it convenient for pipeline pigging to keep the pipeline clean.

The slab gate valve also uses a self-sealing packing structure, which requires no frequent adjustment, allowing for very easy operation and reliable sealing. An auxiliary sealing grease injection structure is arranged at the packing gland to further enhance sealing performance, truly achieving zero leakage and effectively solving the common leakage problem at the packing of general valves. In addition, when the slab gate valve is closed, it can automatically release high pressure from the valve cavity to ensure safe use. With its fully enclosed structure and good protection performance, it can meet all-weather requirements.

2. Advantages and Limitations of Slab Gate Valves

The advantages of slab gate valves are obvious. Their sealing performance is excellent, achieving bidirectional sealing and ensuring inlet and outlet tightness. The operating torque is small, making operation easy and convenient, greatly reducing labor intensity. When fully open, the channel is smooth with minimal flow resistance and no pressure loss, facilitating pipeline pigging. The self-sealing packing structure and auxiliary grease injection enhance sealing performance, achieving zero leakage. In addition, when closed, the valve can automatically release internal high pressure, ensuring safety. The fully enclosed structure makes it suitable for all-weather requirements.

However, slab gate valves also have limitations. At low medium pressure, the sealing force of the metal sealing surface may not be sufficient to achieve a satisfactory seal. Conversely, at high medium pressure, if the sealing surface is not lubricated by the medium or an external agent, frequent opening and closing may cause excessive wear. The gate plate may also vibrate violently when cutting off high-speed and high-density fluid. Moreover, flow control sensitivity only occurs when the gate is around 50% closed, which limits its application in flow regulation.

3. Application Scenarios of Slab Gate Valves

Slab gate valves are suitable for a wide range of industrial fields, with a working pressure range of Class150-900 LB and a working temperature range of -29 to 121℃. They are widely used in petroleum and natural gas transmission pipelines, ensuring the safe transport of energy. Slab gate valves with diversion holes also facilitate pipeline pigging, further improving maintenance efficiency.

In refined oil pipelines and storage facilities, slab gate valves, with their low flow resistance and excellent sealing performance, ensure efficient transportation of oil products and storage safety. In oil and gas wellhead devices, namely, Christmas tree valves, slab gate valves also play an important role in ensuring smooth oil and gas extraction.

In addition, slab gate valves are also suitable for pipelines with suspended particles, such as city gas transmission pipelines and water supply projects. Their low flow resistance and full-bore design make their flow resistance comparable to that of short straight pipes. Slab gate valves with diversion holes installed in pipelines can also be directly cleaned with pigging tools, greatly improving pipeline maintenance efficiency.

Knife Gate Valves: Gate Valves Designed for Special Media

In industrial applications, different media place different demands on valve performance. For some media containing solid particles, fibers, or other complex components, ordinary slab gate valves may not meet the requirements. At this point, knife gate valves, with their unique design and excellent performance, become the ideal choice for handling such special media. Knife gate valves can not only effectively cut fibers and particles in the medium but also maintain reliable sealing under harsh working conditions. Next, we will explore the structure, working principle, application scenarios, and unique advantages of knife gate valves.

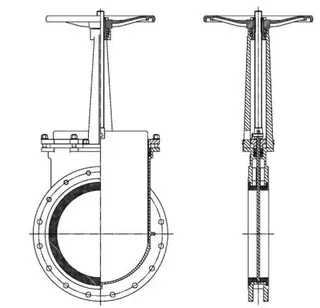

1. Structure and Working Principle of Knife Gate Valves

The knife gate valve is a special form of slab gate valve. It uses a wafer-type connection, with a shorter body length and thinner gate. The bottom of the gate has a knife-shaped bevel, which can cut through fibers in the medium, hence the name "knife gate valve". The opening and closing element is the gate, which moves perpendicular to the flow direction, using a knife-edged plate to cut the medium.

The gate of a knife gate valve has two sealing surfaces. The most common design is a wedge shape, with the wedge angle varying depending on valve parameters, usually about 5°. The wedge-type gate can be made as a rigid gate (one piece) or as an elastic gate capable of slight deformation, which improves manufacturability and compensates for deviations in sealing surface angles during processing. The valve body essentially has no cavity; the gate moves up and down in side guide grooves and is pressed tightly against the seat by a bottom lug. For higher sealing performance, O-ring sealed seats can be selected to achieve bidirectional sealing.

2. Advantages of Knife Gate Valves

Knife gate valves have many unique advantages. The lifting gate sealing surface can scrape off adhered substances, automatically cleaning debris and ensuring sealing performance. Stainless steel gates effectively prevent sealing leakage caused by corrosion, extending service life. Hard alloy sealing surfaces guarantee wear resistance and reliability, maintaining good sealing even under harsh working conditions.

The body sealing surface has no grooves, preventing material accumulation and ensuring flexible operation. Their short structural length not only saves raw materials but also enhances pipeline strength. The scientifically designed stuffing box ensures safe and durable upper sealing. The triangular bracket saves raw materials while maintaining required mechanical strength. The body guide block ensures correct gate movement, while four compression blocks ensure effective gate sealing. Reinforcing ribs on the body increase strength, stainless steel stems are durable, and double-headed bolts make opening and closing quicker.

Knife gate valves can use various actuators. For diameters above DN150, a fully enclosed structure is adopted, enabling more effective opening and preventing leakage. Fluororubber sealing surfaces provide good sealing and increase operating temperature. Rubber sealing surfaces are vulcanized directly onto the valve body, preventing detachment and further enhancing sealing performance.

3. Application Scenarios of Knife Gate Valves

Knife gate valves are widely used in pipeline systems conveying slurry, coal slurry, ore powder, fly ash, pulverized coal, pulp, mud, material-water mixtures, and material-gas mixtures, whether wet or dry media. Their working pressure generally does not exceed PN16. Because they can effectively cut fibers and particles, knife gate valves perform excellently when handling media containing solids and fibers, effectively preventing clogging and leakage.

4. Operation and Maintenance of Knife Gate Valves

The operation of knife gate valves is relatively simple, mainly by turning a handwheel to open or close the valve. When using a knife gate valve, rotating the handwheel actuates internal mechanisms, causing physical movement of internal components to achieve valve opening and closing, thereby controlling the on/off state of the pipeline.

Although the internal structure of knife gate valves is complex, their operation is very fast. Turning the handwheel drives internal levers and gears, which in turn move the blocking device rapidly. Depending on the direction of rotation, the valve opens or closes. This rapid operation saves time and improves efficiency.

Maintenance is also very convenient. The U-shaped sealing gasket provides good sealing, while the full-bore design ensures strong medium throughput. In conditions involving dirty media, knife gate valves are easy to install, disassemble, and repair. The sealing elements can be replaced without removing the valve, greatly simplifying maintenance.

5. Knife Gate Valves vs. Ordinary Gate Valves

Compared with ordinary gate valves, knife gate valves show many distinct differences and advantages. Their structure is simple, with the gate moving perpendicular to the flow. They are compact, flexible, and easy to install, especially suitable for media with higher viscosity or solid particles.

Knife gate valves mainly rely on the knife-edged gate to cut through media, with wedge-shaped sealing surfaces. The gate can be made rigid or elastic, improving sealing performance. Compared to ordinary gate valves, knife gate valves stand out with the following advantages:

U-shaped gasket ensures good sealing, while full-bore design provides strong throughput.

Easy installation, disassembly, and maintenance in dirty media conditions; seals can be replaced without removing the valve.

Knife-edged gate effectively cuts off all kinds of debris in the medium, preventing leakage after shutoff.

Ultra-short structural length results in small size, low flow resistance, light weight, material savings, and minimal space occupation.

Although knife gate valves are about 20% more expensive than ordinary gate valves, their excellent performance has been widely recognized in the market and they are extensively used in various industries.

Slab Gate Valve or Knife Gate Valve?

When choosing between slab gate valves and knife gate valves, decisions should be made based on specific working conditions and requirements. Slab gate valves are suitable for many industrial scenarios, especially petroleum and natural gas pipelines, refined oil pipelines and storage facilities, Christmas tree valves, and pipelines with suspended particles. Their excellent sealing performance, low flow resistance, and automatic pressure relief make them an ideal choice.

Knife gate valves are more suitable for handling media containing solid particles and fibers, such as slurry, coal slurry, ore powder, fly ash, pulverized coal, pulp, and mud. Their unique knife-shaped gate can effectively cut fibers and particles, preventing clogging and leakage. Compact structure, flexible operation, and convenient maintenance also make them especially suitable for use in limited spaces.

When selecting a valve, factors such as working pressure, temperature, medium type, and pipeline size must be considered. By comprehensively evaluating these factors, the most suitable valve can be chosen to ensure the safe and efficient operation of pipeline systems.

Conclusion

As important components of industrial pipeline systems, slab gate valves and knife gate valves each have unique structures, working principles, and application scenarios. Slab gate valves, with their excellent sealing, low flow resistance, and automatic pressure relief, play a crucial role in many industries. Knife gate valves, with their knife-edged gate, compact structure, and efficient cutting ability, are the ideal choice for handling media containing solid particles and fibers.

When choosing valves, specific conditions and requirements must be considered, including working pressure, temperature, medium type, and pipeline size. Proper selection and use of slab gate valves and knife gate valves can effectively ensure the safe and efficient operation of industrial pipeline systems, providing reliable protection for industrial production.

Whether for petroleum and natural gas transmission or slurry and coal slurry handling, slab gate valves and knife gate valves, with their outstanding performance and reliability, have become indispensable equipment in the industrial field. They are not only the guardians of pipeline systems but also strong guarantees for the smooth progress of industrial production.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Comparison between Hot Rolled and Cold Rolled Pipe

- Sep 01, 2014

Comparison between Electric and Pneumatic Actuators

- Jun 29, 2015

Comparison between ABS and PP

- Sep 20, 2017

Comparison Between Forged Aluminum vs Forged Brass

- Apr 14, 2024

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/comparison-between-slab-gate-valves-and-knife-gate-valves.html