Bolted Bonnet Knife Gate Valves, ASTM A216 WCB, DN200, PN16

Product Name: Bolted Bonnet Knife Gate Valves

Type: Unidirectional Knife Gate Valve

Body Material: ASTM A216 WCB

Size: DN200, 8 Inch

Pressure: PN16, Class 150 LB

End Connection: Wafer/Lug

Operation: Pneumatic Actuator

Temperature Range: -29°C to 538°C

Medium: Used for pulp, coal ash, sewage, food, etc

The BU series knife gate valve is a unidirectional knife gate valve with a bonnet. The completely enclosed body-bonnet structure ensures zero leakage from the knife gate to the surroundings. This valve is highly suitable for contaminated or hazardous media, ensuring the safety of the surrounding environment.

Technical Specification

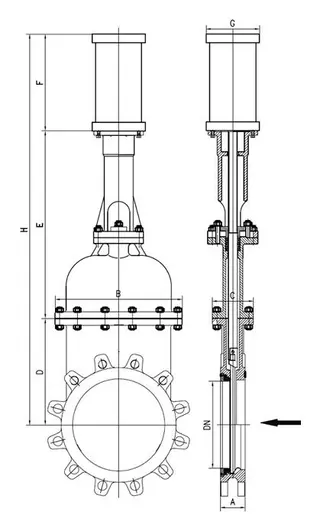

» Structure: Unidirectional wafer knife wedge gate valve

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: PN10, PN16, Class 150 LB

» Temperature Range: -29°C to 538°C

» Max Working Pressure:

DN50-DN250: 10 bar

DN300-DN450: 7 bar

DN500-DN600: 4 bar

» Body Material: Carbon Steel, Stainless Steel, Special Alloy, etc.

» Disc Material: Stainless Steel Chrome Plated, Special Alloy, etc.

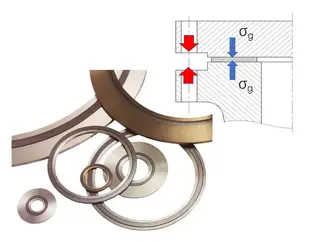

» Seat Material: Stainless Steel + STL, EPDM (120°C), Viton (200°C), PTFE (200°C), NBR (80°C)

» Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN 1092-1

» Face to Face: MSS SP-81

» Applications: Pulp & Paper, Water Treatment, Beverage & Food, Fine Chemicals, Power Plants, Steel Industry, etc.

Structural Diagram

Product Features

» Cast-in guide claws at the port bottom, instead of a groove, eliminate potential valve shutoff clogging while providing a tight seal. These guide claws push the gate towards the seat for a secure seal in the closed position.

» Integral body design ensures easy assembly and zero shell leakage.

» Full-port design minimizes pressure drop and maximizes flow capacity.

» Completely enclosed structure ensures zero leakage from the valve to the surroundings, making it ideal for contaminated or hazardous media to ensure environmental safety.

» Super-thin body design and compact construction allow easy installation.

» Beveled knife edge provides strong cutting force and tight sealing.

» Gate thickness can be increased to meet higher pressure requirements.

» Side-entry seat is replaceable, reducing maintenance costs.

» L-shaped seat retainer locks the seat into the valve body and covers the seat side to prevent direct flow flushing.

» Stem cover is available to extend stem service life.

» Two thrust bearings minimize operating torque.

» Grease nipple is available for easy bearing lubrication.

Send your message to this supplier

Related Articles from the Supplier

Features of Bolted Bonnet Gate Valves

- Dec 14, 2024

Related Articles from China Manufacturers

Bolted Bonnets vs. Pressure Seals for Valves

- Dec 05, 2023

Bolted Flanges

- Dec 22, 2021

The Research Method of Tightness of Bolted Flanges

- May 10, 2021

Current Status of Research on Bolted Flanges

- Jan 06, 2022

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/bolted-bonnet-knife-gate-valves-astm-a216-wcb-dn200-pn16.html