ASTM B148 C95800 Butterfly Valves, API 609, 32 IN, CL150

Product Name: ASTM B148 C95800 Triple Eccentric Butterfly Valve

Design Standard: API 609

Body Material: Bronze ASTM B148 C95800

Shaft Material: MONEL K500

Size: 32 Inch, DN800

Pressure: Class 150 LB, PN20

End Connection: Lug

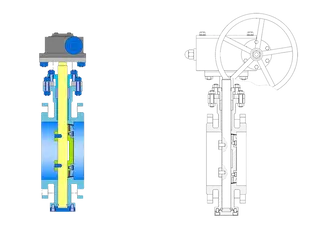

Operation: Wormgear

We offer a wide range of Triple Eccentric Butterfly Valves, available in various pressure classes, body styles, and materials to meet critical process requirements across industries such as hydrocarbons, power, chemicals, and fertilizers. The product range includes valves in ASME classes up to 600 LB, with sizes up to 64 Inch (DN1600 mm), available in carbon steel, stainless steel, and alloy steels, suitable for temperatures up to 538°C (1000°F). Custom valves for higher pressure classes, larger sizes, and other materials are available upon request, with options for cryogenic services. These metal-seated valves adhere to API 609 standards. KOSEN's Triple-Offset Butterfly Valves are bi-directional and provide high-integrity sealing. All machining is performed on 5-axis machining centers, and specialized welding machines are used for manufacturing these valves.

Product Range

Size Range: 2-40 Inch (DN50-DN1000) (Larger sizes available upon request)

Pressure Ratings: Class 150 LB, PN10, PN16

Body Material: Bronze ASTM N148 C95800

Shaft Material: MONEL K500

Seat Material: PTFE

Operation: Handle, Worm Gear, Pneumatic, Electric

Temperature Range (Metal Seat): -29°C to 150°C

Medium: seawater, etc

End Connections: Wafer, Lugged, Double Flanged, Butt Weld, or Grooved

Actuations: Manual, Pneumatic, Electric, Hydraulic, Counterweight, Electro-Hydraulic

Product Features

» Lockable lever for secure operation

» Easy site maintenance for convenience

» Simplified automation for efficient control

» Positive tight shut-off for reliable sealing

» Optional top flanges conforming to ISO 5211 for easy actuator mounting

» Suitable for both gaseous and liquid services

» Broad range of body and trim materials available for various medium services

» Compliant with ISO 5752, BS 5155, API 609, MSS-SP-68, ASME B16.10, ASME B16.5, and DIN 3202 standards

Triple Offset Butterfly Valve

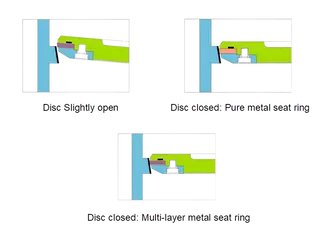

Triple offset metal sealing butterfly valve uses the three eccentric structure with multi-layer metal seal or pure metal sealing ring, different sealing materials are being used according to the different temperature request from end user.The structure of valve sealing ring that was formed after machining for triple eccentric butterfly valve is oblique cone type, the purpose of which is to let the disc open in a subtle angle and seat sealing surface can be completely separated from the sealing surface of disc, thus to reduce the friction of sealing surface during the open and close.

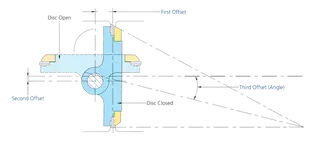

Triple Offset Frictionless Design

- Offset 1: Offset for seat seal and the rotation center of stem.

- Offset 2: Center of pipe and disc.

- Offset 3: Seat sealing angle center line and flow passage center.

- The triple offset of butterfly valve ensures the valve disc is completely separated from seat sealing surface while open in a slightly angle which could reduce the friction of sealing surface during open and close and opening torque as well as prolong the service life of the sealing surface.

- Our metal sealing butterfly valve adopts multi-layer sealing ring to achieve the valve seal, the multi-layer seal ring is generally made of stainless steel and graphite combination The pure metal sealing can be used for special medium or high temperature.

Seat Structure

- Low Operating Torque: Our butterfly valves combine three offsets. Standard sealing is graphite + metal. Optional PTFE + metal combinations are available for different temperatures and media, using flexible laminated metal and graphite to ensure a tight, uniform seal and reduce operating torque.

- Zero Leakage: Laminated seal rings are self-aligning, allowing the valve to meet zero leakage per API 598.

- Fire-Safe Design: Standard valves are not soft-seated and meet API 607 fire-safe requirements.

- Anti-Blowout Shaft: Double anti-blowout design meets API 609 and ASME B31.1.

- Top Retention: Packing gland follower retains the stem.

- Bottom Retention: T-shaped collar prevents stem blowout.

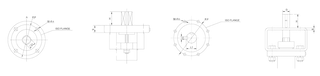

ISO 5211 Top Mounting

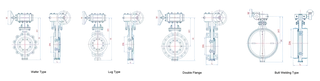

Different End Connections Available:

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

ASTM B148 C95800 ball valves

- Apr 08, 2021

ASTM Carbon B Weather Resistant Steel Sheet/Plate

- Nov 30, 2016

ASTM A53

- Oct 21, 2016

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/astm-b148-c95800-butterfly-valves-api-609-32-in-cl150.html