Common Issues and Solutions for Aeration Butterfly Valves

On this page

Aeration butterfly valves play a crucial role in industrial and building ventilation systems. However, in practical applications, these valves may encounter various issues that can affect their normal operation. Understanding the causes of these faults and mastering the corresponding solutions can effectively improve the working efficiency and service life of aeration butterfly valves.

3. Fluctuation in Medium Flow Rate

Significant changes in the medium flow rate cause unstable flow control.

Aeration Butterfly Valve

Sealing Failure

Causes

1. Seal Face Wear

Prolonged use can lead to wear on the seal face, affecting sealing performance.2. Contaminants Ingress

Contaminants entering the seal face from the pipeline can compromise the sealing integrity.3. Seal Material Aging

Aging of seal materials can reduce elasticity, leading to seal failure.Solutions

1. Replace Seals

Regularly inspect the condition of seals and replace them if necessary.2. Remove Contaminants

Ensure that the pipeline and valve interior are clean to prevent contaminants from entering the seal face.3. Use Durable Materials

Choose wear-resistant and corrosion-resistant sealing materials based on the working environment to extend the lifespan of the seals.Lack of Operational Flexibility

Causes

1. Insufficient Lubrication

Lack of lubrication on the valve stem and bearings can lead to difficulty in operation.2. Valve Body Deformation

Uneven force or improper installation can cause deformation of the valve body, affecting operation.3. Foreign Object Obstruction

Foreign objects entering the valve body can jam the valve plate or stem.Solutions

1. Regular Lubrication

Periodically check the lubrication of the valve stem and bearings, and add lubricant as needed.2. Installation Check

Ensure the valve is installed correctly and properly aligned to avoid deformation due to uneven stress.3. Foreign Object Removal

Regularly clean the interior of the valve body to prevent foreign objects from causing jams.Corrosion of Valve Body

Causes

1. Medium Corrosion

Chemical reactions between the valve body material and the medium cause corrosion.2. Environmental Factors

External environmental conditions, such as humidity or corrosive gases, lead to external corrosion of the valve body.Solutions

1. Select Corrosion-Resistant Materials

Choose appropriate valve body materials based on the characteristics of the medium, such as stainless steel or special alloys.2. Corrosion Protection Treatment

Apply anti-corrosion coatings to the valve body surface to extend its service life.3. Improve Environment

Optimize the installation environment to avoid prolonged exposure of the valve to corrosive gases or humid conditions.Leakage Issue

Causes

1. Damage to the Sealing Surface

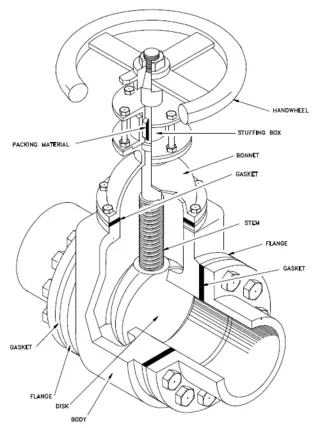

Damage to the sealing surface can lead to leaks.2. Loose Flange Connections

Loose flange bolts can result in leaks.3. Cracks in the Valve Body

Material defects or excessive stress can cause cracks in the valve body, leading to leaks.Solutions

1. Repair the Sealing Surface

Polish and repair the sealing surface or replace damaged components.2. Tighten Flange Bolts

Regularly inspect flange connections to ensure bolts are tightened and replace gaskets if necessary.3. Replace the Valve Body

Replace the valve body promptly if cracks are found to prevent safety incidents.Unstable Flow Control

Causes

1. Valve Adjustment Failure

The valve adjustment mechanism fails, leading to unstable flow control.2. Actuator Malfunction

The actuator (such as electric or pneumatic actuators) malfunctions, preventing the valve from adjusting accurately.3. Fluctuation in Medium Flow Rate

Significant changes in the medium flow rate cause unstable flow control.

Solutions

1. Inspect the Adjustment Mechanism

Regularly check the valve adjustment mechanism to ensure it operates smoothly and reliably; perform repairs or replacements as needed.2. Maintain the Actuator

Regularly maintain the actuator to ensure its proper operation; replace any faulty components as necessary.3. Stabilize Flow Rate

Optimize the system to maintain a stable medium flow rate, ensuring precise flow control.Send your message to this supplier

Related Articles from the Supplier

Common Sense of Valve Body Strength Test

- Aug 11, 2015

Common Valve Problems 1

- Aug 17, 2015

Common Valve Problems 2

- Aug 26, 2015

Common Faults and Solutions of Marine Valves

- Oct 24, 2015

Common Faults and Preventive Measures of Gate valves

- Jul 26, 2016

Related Articles from China Manufacturers

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kellyvalve.com/news/common-issues-and-solutions-for-aeration-butterfly-valves.html