Alloy Steel Forging: Process, Quality & Uses

In today's industrial manufacturing field, alloy steel forged products play an indispensable role. They are widely used across numerous key areas, including power generation, energy, metallurgy, pressure vessels, military industry, marine engineering, construction machinery, industrial manufacturing, railway transportation, and automotive manufacturing, due to their many advantages such as high production efficiency, excellent mechanical properties, material savings, and lightweight characteristics. These products achieve the desired shapes, dimensions, and performance through plastic deformation of metal billets under pressure, becoming core materials for various key parts or blanks.

Principles of Alloy Steel Forging

The process of alloy steel forging can be simply understood as heating the metal to a specific temperature, making its crystal lattice structure more malleable and providing excellent plasticity. During forging, the application of external force causes the metal to undergo plastic deformation; its shape changes without fracturing. This occurs because metal grains are compressed and stretched during forging, refined, and rearranged, significantly improving the material's mechanical properties, such as strength, toughness, and hardness. At the same time, the pressure during forging can expel internal gas holes and impurities from the metal, making the material denser and enhancing its load-bearing capacity and durability. Through different forging processes and die designs, the shape and dimensions of metal parts can be precisely adjusted to meet the manufacturing requirements of various complex components.

Classification of Alloy Steel

There are many types of alloy steel, generally including alloy structural steel, alloy tool steel, high-speed steel, high-chromium die steel, stainless steel, and high-temperature alloys. Due to differences in chemical composition, the forging methods for these steels also vary. For example, high-speed steel and high-chromium die steel are mostly used for mold manufacturing. To break the internal carbides, the billets need repeated forging to meet standard requirements, thereby satisfying usage requirements. For alloy structural steel, alloy tool steel, stainless steel, and high-temperature alloys, which have wider applications for medium and small mechanical parts, die forging is generally used to produce blanks when production is in larger batches.

Selection of Alloy Steel Forging Methods

When selecting a forging method, factors such as chemical composition, intended use, and production volume must be comprehensively considered. For high-speed steel and high-chromium die steel, which are mainly used to make molds and require carbide breaking, open-die forging or specialized forming methods such as multi-roll rolling and hot extrusion are mostly adopted. For alloy structural steel, alloy tool steel, stainless steel, and high-temperature alloys, which have wide applications and larger production volumes, die forging is the preferred method. Die forging ensures dimensional accuracy and the complexity of forged shapes, improves production efficiency, and reduces production costs.

Advantages of Alloy Steel Forging

Alloy steel forged products are highly favored mainly due to their remarkable advantages. First, in terms of production efficiency, the forging process allows high-efficiency production, meeting the needs of large-scale industrial manufacturing. Second, in terms of material performance, forged alloy steel has excellent mechanical properties, able to withstand high-intensity impact and heavy loads, maintaining stable and reliable performance in harsh working environments. Additionally, the forging process ensures efficient use of raw materials, saving materials and reducing production costs. At the same time, optimized design and process allow lightweighting of products, which is extremely important for applications with strict weight requirements, such as aerospace and automotive manufacturing.

Key Processes in Alloy Steel Forging

Next, we delve into the key process points of alloy steel forging. These points are critical to ensuring smooth forging operations and producing high-quality forgings. Only by mastering these process points can the performance advantages of alloy steel be fully realized to meet the stringent requirements of various industrial applications.

1. Hot Die Forging Methods to Improve Plasticity

Due to the complex chemical composition and relatively poor forgeability of alloy steel, hot die forging methods that improve plasticity must be used whenever possible during forging. These methods include restricted flash die forging, flashless die forging, extrusion die forging, flat-die forging, and enclosed-die forging. Sometimes hot forging methods may also be considered. The goal is to place the billet under triaxial compressive stress in the die cavity to improve its plasticity, thereby enhancing the formability of the alloy steel and ultimately obtaining the desired forged part.

2. Raw Materials and Blanking Methods

Alloy steel die forging commonly uses rolled or extruded bars of various cross-sections as raw materials. Blanking methods generally include shearing or turning. Choosing the appropriate raw materials and blanking methods is crucial to ensure forging quality and production efficiency. The quality of raw materials directly affects the performance of forgings, while a reasonable blanking method can reduce material waste and lower production costs.

3. Forging Classification and Design

Alloy steel forgings come in a wide variety of types depending on their application. To facilitate process formulation and selection of the appropriate forging method, a standard design procedure is generally adopted. Forgings are classified into long-shaft, short-shaft, and blade types based on their external structure. The first two types are the same as general carbon steel forgings, while blade forgings mainly refer to components such as compressor and turbine blades in engines, steam turbine blades, and thin forgings whose thickness is far smaller than length and width. When designing forgings, the usage requirements, stress conditions, and feasibility of the forging process must be fully considered to ensure the forging meets performance requirements while being manufacturable.

Quality Control in Alloy Steel Forging

However, mastering process points alone is not enough; strict quality control is equally essential. Quality control in alloy steel forging runs throughout the entire production process, from precise control of chemical composition, fine-tuning of heating processes, to reasonable setting of forging parameters, with each step directly affecting the final product quality.

1. Chemical Composition Control

Alloy element content in alloy steel forging standards must be strictly controlled within specified ranges. For example, chromium (Cr) content is generally 0.5%–2.5%, nickel (Ni) 0.3%–4.5%, and molybdenum (Mo) 0.15%–0.6% to ensure specific performance. Impurity elements in raw materials, such as sulfur (S) ≤0.03% and phosphorus (P) ≤0.035%, prevent hot and cold brittleness. Strict chemical control is the foundation for stable alloy steel performance.

2. Heating Process Control

The furnace temperature uniformity should be controlled within ±15°C to ensure uniform billet heating. Depending on billet size and alloy content, heating rates are generally 50–150°C/h, with larger or high-alloy billets using lower rates. For some high-alloy steels, preheating temperatures are generally 600–800°C to reduce thermal stress. The starting forging temperature varies by alloy type, generally 1050–1250°C, and finishing forging temperature is usually 800–950°C, ensuring plastic deformation without work hardening or cracking. Proper heating ensures good plasticity and reduces forging defects, improving forging quality.

3. Forging Parameter Control

The forging ratio is generally 3–5, and for important forgings, it may reach 5–8 to improve microstructure and performance. Deformation speed should be adjusted according to alloy type and equipment, generally 0.1–10 s⁻¹. Cooling methods include air cooling, pit cooling, or furnace cooling; high-alloy steel forgings generally use furnace cooling at 20–50°C/h. Proper forging parameters ensure good microstructure and performance while preventing defects or cracks.

4. Heat Treatment Process

Post-forging heat treatment includes annealing, normalizing, quenching, and tempering. Annealing temperature is generally 700–850°C, normalizing 850–950°C, quenching 800–1050°C, and tempering 150–650°C depending on performance requirements. Heat treatment further improves microstructure and mechanical properties such as hardness, strength, and toughness, meeting diverse usage requirements.

5. Quality Inspection

Forgings must be free from cracks, folds, and scabs, with surface roughness Ra ≤12.5 μm. Dimensional tolerances must meet relevant standards, generally length ±1.5 mm, diameter ±1.0 mm. Internal quality inspection uses ultrasonic testing or magnetic particle inspection, with sensitivity meeting standards (ultrasonic detection sensitivity not less than Φ2 flat-bottom hole equivalent). Mechanical properties such as tensile strength, yield strength, elongation, and impact toughness must meet relevant standards—for example, low-alloy structural steel forgings require tensile strength ≥450 MPa and yield strength ≥275 MPa. Strict quality inspection ensures forging quality meets standards, providing reliable support for subsequent processing and use.

Applications of Alloy Steel Forgings

Alloy steel forged products have extensive applications across industrial fields. In power and energy, they are used to manufacture critical components such as generator rotors and turbine blades, ensuring equipment stability and reliability under high loads and prolonged operation. In metallurgy, rolls and molds rely on alloy steel forging. In pressure vessel manufacturing, alloy steel forgings withstand high pressure and temperature, ensuring safe operation. In military industries, from tank armor plates to aircraft engine components, alloy steel forgings play a vital role. In marine engineering, key components such as ship propellers and rudders require alloy steel forgings to ensure strength and corrosion resistance. In construction machinery, railway transportation, and automotive manufacturing, alloy steel forgings are ubiquitous, providing solid support for the normal operation of machinery.

Conclusion

In conclusion, alloy steel forging, with its excellent mechanical properties, superior durability, and flexible and diverse process methods, has become an indispensable cornerstone of modern industrial manufacturing. From raw material selection, heating and forging processes, to strict quality control and heat treatment, every step ensures the high performance and reliability of forgings. Whether in energy, power, metallurgy, military, marine, automotive, or machinery manufacturing, alloy steel forged products support the production and application of key components with their solid, durable, precise, and reliable characteristics, highlighting their core value and irreplaceable position in industrial manufacturing.

Send your message to this supplier

Related Articles from the Supplier

Alloy Steel Forging: Process, Quality & Uses

- Nov 27, 2025

Analysis of Defects in Zinc Alloy Die Casting

- Oct 28, 2024

What Influence Aluminum Alloy Casting Quality

- Nov 06, 2024

Related Articles from China Manufacturers

Alloy Steel Drop Forgings,Hot forging

- Mar 20, 2024

High-Temperature Alloy Steel Forging Processes

- Nov 28, 2024

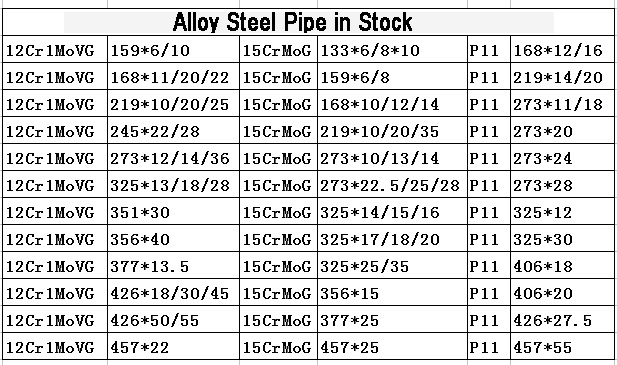

Alloy Steel Pipe in Stock

- Mar 01, 2017

Alloy Steel Pipe Fittings

- Mar 29, 2023

Process Flow of 16Mn Alloy Steel Pipes

- Jun 19, 2020

Related Products Mentioned in the Article

Supplier Website

Source: http://www.forging-casting-stamping.com/alloy-steel-forging-process-quality-uses.html

.png)