Research on Shut-off Valve Selection for the LNG Industry

Abstract: Driven by the “dual carbon” goals, the demand for natural gas and the LNG import market are expanding, making the stable and efficient operation of LNG receiving terminal equipment increasingly critical. As a key component at the end of the pipeline, the proper selection of shut-off valves is essential to ensuring the safety and reliability of the receiving terminal. Based on the SH/T 3005 Specification for the Selection and Design of Petrochemical Automation Instruments, this article systematically outlines the key considerations for shut-off valve selection in LNG receiving stations, covering four aspects—valve type, valve body, actuator, and accessories—while incorporating process flow requirements to support scientific design and selection. The global transition to clean energy is accelerating, with liquefied natural gas (LNG) emerging as a key energy source. In alignment with China’s “carbon peak” and “carbon neutrality” strategies, demand for natural gas and LNG imports continues to grow. As a critical link between maritime transport and onshore pipeline networks, the stable and efficient operation of LNG receiving terminal equipment is essential. As terminal-actuated devices in process pipelines, shut-off valves must be carefully selected to ensure the safety and reliability of the receiving terminal. If valve performance does not meet operating requirements, leakage may occur, and the flammable, explosive, and cryogenic properties of LNG can pose severe risks to both facilities and personnel. Therefore, valve design and selection must prioritize suitability for specific process requirements and pipeline materials, taking into account valve type, materials, accessories, actuators, and switching times. Strict adherence to selection procedures is essential for achieving accurate and well-founded valve selection.

1. Valve Types

Shut-off valves primarily include ball valves, butterfly valves, gate valves, and globe valves. Selecting the appropriate shut-off valve type requires consideration of media characteristics, operating environment, pipeline dimensions, and valve switching time. Media characteristics primarily include pressure, temperature, viscosity, corrosiveness, flow rate, solids content, bidirectional flow, and the presence of impurities.

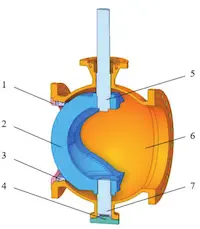

1.1 Ball Valves

Shut-off ball valves operate by using an actuator to rotate the valve stem, which in turn rotates the valve core to open or close the valve. A full-bore ball valve has a valve core with a circular channel that matches the pipe diameter. Its simple structure provides advantages such as easy maintenance and high operational reliability. Shut-off ball valves utilize linear sealing. When closed, the valve core’s circular channel is misaligned with the valve seat, ensuring complete blockage of the medium and high-pressure sealing, thereby guaranteeing the safe and stable operation of the receiving terminal system. When fully open, a full-bore ball valve preserves the flow direction of the medium, resulting in low flow resistance and a resistance coefficient effectively equal to that of a pipe of the same length. Furthermore, in both fully open and fully closed positions, the sealing surfaces do not come into direct contact with the medium, thereby reducing corrosion and damage and extending the valve’s service life. Therefore, full-bore ball valves are the preferred choice for applications demanding high sealing and pressure ratings, and they are the most widely used shut-off valves in LNG receiving terminals.

1.2 Butterfly Valves

Shut-off butterfly valves use an actuator to rotate the valve stem, which then rotates the butterfly disc to open or close the valve. During operation, the medium applies nearly balanced and opposing torques on both sides of the disc, resulting in a required opening and closing torque that is significantly lower than that of ball valves. This makes butterfly valves particularly well-suited for large-diameter, high-flow applications. Compared to ball valves, butterfly valves require less pipeline space, facilitating installation in confined areas. When fully open, the butterfly disc presents minimal flow resistance, delivering excellent flow capacity and making it well-suited for rapid on/off operation and high-volume flow control. According to the SH/T 3005 Specification for the Selection and Design of Petrochemical Automation Instruments, gate valves, triple-eccentric butterfly valves, or double-eccentric high-performance butterfly valves are recommended for pipelines with nominal diameters exceeding 200 mm. In LNG receiving terminal projects, large-diameter butterfly valves are commonly employed in export pipelines, high-pressure pump inlet lines, tank feed lines, and dock unloading lines. Triple-eccentric butterfly valves, characterized by three eccentric parameters—eccentric angle, eccentric position, and eccentric distance—achieve zero friction during opening and zero contact during closing. This design effectively prevents damage to the sealing surface, extends service life, and ensures reliable bidirectional pressure sealing. As a result, triple-eccentric butterfly valves are widely used in large-diameter pipelines.

1.3 Gate Valves

The gate valve’s opening and closing function is achieved by the actuator moving the disc axially up and down. When closed, the valve relies on medium pressure to press the disc’s sealing surface firmly against the seat, creating a tight seal. Therefore, gate valves are especially well-suited for large-diameter pipelines, high flow rates, and applications involving significant pressure differentials.

1.4 Globe Valves

According to the SH/T 3005 Specification for the Selection and Design of Automatic Instruments for Petrochemicals, globe valves are generally not recommended for use as shut-off valves. This is due to their inherent structural characteristics and mode of operation. These valves rely on the stem to press the disc against the seat sealing surface to block the flow of the medium. However, this closing mechanism can cause impurities or solid particles in the flow to become trapped between the sealing surfaces during shutoff. This not only leads to poor sealing and leakage but also accelerates wear on the sealing surfaces due to the repeated compression of foreign matter, thereby shortening the valve’s service life. For these reasons, globe valves are generally not used as shut-off valves in LNG receiving terminals.

2. Valve Bodies

When selecting a shut-off valve, key valve body parameters include pressure rating, material, connection type, and structural design. These should be selected based on the requirements of upstream disciplines such as process engineering, utilities, and piping materials. Relevant factors include operating flow, pressure, temperature, full-stroke actuation time, fire protection requirements, valve position during power failures, pipeline material, and pressure rating. This article focuses on cryogenic shut-off valves used in LNG terminals where the process medium is LNG, but the selection principles can also serve as a reference for other operating conditions.

2.1 Valve Pressure Rating

As energy facilities with complex structures and high operational risks, ensuring that the shut-off valve’s pressure rating matches the pipeline’s pressure rating is critical not only for the safe operation of the terminal but also for its economic efficiency. This is reflected in two key aspects:

- If the shut-off valve’s pressure rating is lower than that of the pipeline, components such as the valve body and seat may not withstand the medium’s high pressure, leading to deformation or damage and ultimately valve failure.

- Such failure can lead to LNG leakage, causing significant economic losses and posing serious safety hazards.

Due to LNG’s cryogenic properties, it absorbs substantial heat and vaporizes rapidly, forming a flammable and explosive vapor cloud that could trigger severe explosions, resulting in even greater economic losses and potential casualties. Conversely, if the valve’s pressure rating is excessively high, the valve cost will increase significantly, resulting in higher capital investment during project construction. Additionally, valves with higher pressure ratings are typically heavier, which complicates installation and raises maintenance costs, thereby increasing the overall operating expenses of the receiving terminal. Therefore, during design and selection, it is essential to ensure that the shut-off valve’s pressure rating matches the pipeline’s pressure rating. The specification requires the valve body pressure rating to be at least PN50 (CI300). In addition to the valve body, supporting components such as flanges and seals must have pressure ratings consistent with the pipeline to prevent any single part from becoming a weak link in the pressure system and causing unnecessary losses.

2.2 Valve Materials

Valve material is generally determined by the pipe material specifications provided by the pipe manufacturer and the requirements outlined in the valve data sheet. Typically, carbon steel or low-temperature carbon steel is used. For shut-off valves in receiving stations, due to the cryogenic nature of LNG, the valve body material is usually selected from low-temperature austenitic castings, such as CF8M (corresponding to UNS S31603, commonly known as AISI 316 stainless steel) under the ASTM A351 standard. This material contains molybdenum, which offers excellent corrosion resistance and low-temperature toughness, ensuring the valve operates reliably under cryogenic conditions and preventing valve body cracking or seal failure caused by prolonged exposure to low temperatures—issues that could otherwise result in economic losses and safety hazards. Based on previous project experience, the valve core and seat materials of low-temperature shut-off ball valves and low-temperature shut-off butterfly valves differ slightly. Low-temperature shut-off ball valves typically use A182-F316 as the valve core material. This grade is similar to CF8M but has a slightly lower carbon content, which further enhances its resistance to intergranular and stress corrosion, making it suitable for the rotating core component of ball valves in cryogenic environments. The valve seat is made of polytetrafluoroethylene (PTFE), which resists LNG’s low-temperature corrosion and offers excellent sealing performance along with low operating torque. Low-temperature shut-off butterfly valves often use CF8M for the valve disc, combined with sealing rings. The excellent low-temperature performance and corrosion resistance of CF8M stainless steel ensure stable operation of the butterfly disc under cryogenic conditions, while the sealing rings provide a reliable seal between the disc and valve seat. The valve seat is also made of CF8M with a hardened surface. Surface hardening typically involves carbide cladding, nitriding, or chrome plating to enhance wear and erosion resistance, ensuring a reliable seal even under frequent switching or when handling particulate-laden media.

2.3 Valve Structure

First, a shut-off valve with bidirectional sealing trim should be selected for the inlet and outlet manifolds of the receiving station. Second, the valve core should be manufactured from a single piece of metal and fitted with a blowout prevention device. The bonnet type should be selected appropriately based on the operating temperature to ensure high sealing performance, safety, and durability under various conditions. Common bonnet types include conventional, long-neck, and extended finned designs. Due to the cryogenic nature of LNG media, the pipeline’s outer layer will have varying insulation thicknesses. Therefore, it is essential to inform the manufacturer of the insulation thickness at the valve installation site. This enables the manufacturer to select a bonnet structure that accommodates the insulation thickness, preventing the insulation from exceeding the valve stem length and obstructing actuator installation. LNG is liquefied methane at extremely low temperatures, with an expansion ratio exceeding 600. When a ball valve is closed, the LNG remaining inside the valve core gradually expands as the temperature rises, generating excessive pressure within the valve. If not relieved, this pressure can damage the valve seal. To prevent this, the ball valve must have a bleed hole that allows the residual LNG to be promptly discharged after the valve closes. The bleed direction is generally chosen as either upstream or downstream, depending on the process conditions.

2.4 Valve Connection Types

For shut-off valves handling LNG as the process medium, the upstream and downstream pipeline connections are typically made by butt welding or flange connection. All parameters for butt-welded connections must comply with the relevant requirements of ASME B16.25. It is also necessary to specify that the valve manufacturer supplies welded stub pipes on both sides of the valve, with materials and wall thicknesses matching those of the adjacent pipeline. Welds must undergo X-ray inspection and be accompanied by a corresponding inspection report. The length of the welded stub pipes must comply with applicable pipe material regulations. When the shut-off valve is connected via flanges, the flange body must comply with ASME B16.5 requirements, while the gaskets, bolts, and nuts must meet the respective standards of ASME B46, ASTM A193, and ASTM A320.

3. Valve Actuators and Accessories

3.1 Actuators

According to the SH/T 3005 Specification for the Selection and Design of Petrochemical Automation Instruments, pneumatic actuators are preferred for shut-off valves when the plant has a reliable instrument air system. Electric actuators, due to their complex internal structure, tend to have higher failure rates and often encounter issues such as insufficient positioning accuracy, excessive switch travel, motor burnout, and gearbox wear, all of which increase maintenance costs. Additionally, frequent adjustments can cause motor overheating and premature wear of the reduction gears. Therefore, pneumatic actuators should be the preferred choice during valve selection. In areas where a reliable instrument air supply is unavailable and electric actuators are required, the power supply system should meet a Class 1 load rating. Shut-off valve actuators typically have three primary fault position states: fail-open (FO), fail-close (FC), and fail-hold (FI). Based on experience from previous LNG terminal projects, single-acting spring-cylinder actuators are typically used for fail-closed (FC) and fail-open (FO) valves, with the valve manufacturer responsible for applying corrosion-resistant treatment to the spring surfaces. Double-acting cylinder actuators with air storage tanks are used for fail-in-place (FI) valves, and the air storage capacity must be sufficient to maintain the valve position for at least 48 hours. The spring range of a shut-off valve is a technical parameter that must comply with process and safety requirements. Generally, the minimum full stroke time (in seconds) for a standard shut-off valve equals the valve body size (in inches), while the maximum full stroke time is three times the valve body size. For emergency shut-off valves, the full stroke time should not exceed 10 seconds regardless of size. Specific requirements are detailed in the conditions table provided by the process specialist. For particularly large emergency shut-off valves where a 10-second full stroke time is not feasible, upstream disciplines—including process, pipeline, and valve manufacturers—must collaboratively determine the final stroke time based on actual operating conditions, valve performance, and project requirements.

3.2 Solenoid Valves

The solenoid valve serves as the control element for the shut-off valve actuator. In previous LNG receiving terminal projects, 2-position, 3-way solenoid valves were generally selected for fail-close (FC) and fail-open (FO) single-acting actuators, while 2-position, 4-way or 2-position, 5-way solenoid valves were commonly used for fail-hold (FI) double-acting actuators. These solenoid valves are typically supplied by manufacturers with a 24 V DC power supply, power consumption of 4 W or less, and a minimum protection rating of IP65. For shut-off valves connected to Emergency Shutdown (ESD) systems, in addition to these requirements, both the valve body and actuator must comply with SIL 2 certification as recognized by the China National Certification and Accreditation Administration. Some projects additionally require the solenoid valve to meet SIL 3 certification.

3.3 Limit Switches

Previous LNG projects often used NUMAR limit switches for shut-off valves. These switches require a minimum protection rating of IP65, and their explosion-proof ratings must comply with the plant-wide hazardous area classifications established by the electrical engineering department.

4. Conclusion

With the ongoing expansion of the LNG industry, shut-off valves are playing an increasingly vital role in LNG receiving terminals. Scientific and rational selection and design based on the valves’ pipeline operating conditions are fundamental to ensuring the safe and reliable operation of receiving terminals. The selection process must incorporate process conditions provided by upstream professionals and verify component parameters according to applicable specifications to ensure the valve’s performance is fully matched to operating conditions. This article focuses on shut-off valves operating under low-temperature conditions in LNG receiving terminals, analyzing key selection considerations for valve type, valve body, actuator, and accessories. Combined with process conditions, this overview aims to serve as a valuable reference for industry professionals.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.baltic-valve.com/research-on-shut-off-valve-selection-for-the-lng-industry.html