Micro-Crack Aging Detection Technology for Globe Valve Stems in Nuclear Power Applications

Abstract: Microcracks in the stems of globe valves used in nuclear power plants are often caused by substandard stem materials, improper heat treatment, stress concentration, pitting, intergranular corrosion, and mechanical overload during valve operation. These microcracks can lead to valve stem fractures, posing serious risks to the safe operation of nuclear power units. Considering the high maintenance workload and the fact that globe valves cannot be reused after disassembly and inspection, this study presents a specialized aging detection technology designed to identify microcracks in globe valve stems. The proposed method enables accurate detection of hidden microcracks in critical, fracture-prone areas of valve stems, significantly reducing maintenance time while enhancing operational safety and reliability in nuclear power plants.

1. Research Background and Necessity

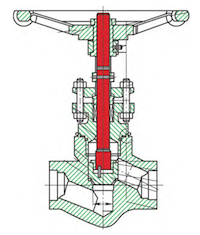

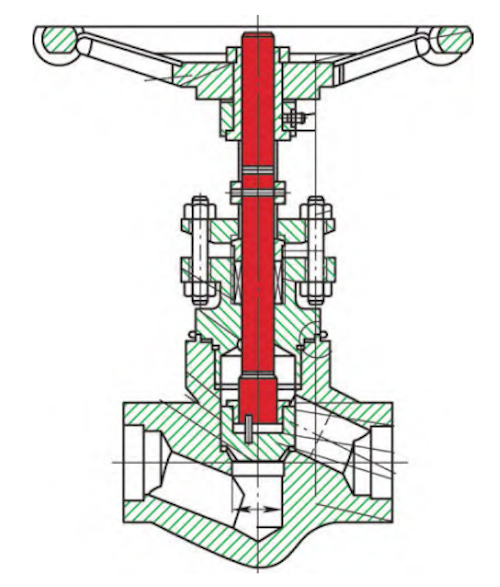

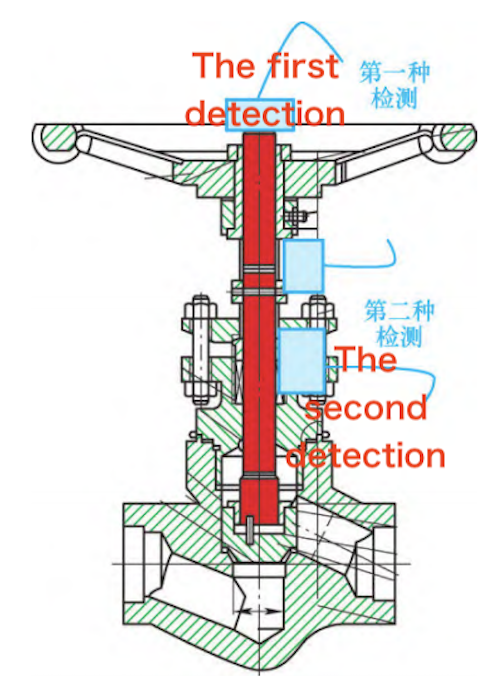

Globe valves are forced-sealing valves that use torque applied to the stem to press the valve disc tightly against the seat, effectively preventing fluid flow. This mechanism enables the valve to perform its key functions of flow control, shut-off, and regulation. The sealing performance of globe valves plays a critical role in ensuring the safety and reliability of nuclear power plant operations. However, fractures in the valve stem frequently occur due to factors such as improper stem materials, inadequate heat treatment, stress concentration, surface pitting, intergranular corrosion, and mechanical overload during valve operation. These fractures pose serious risks to the safe operation of nuclear power units. The valve stem—a critical component that connects the valve core to the operating mechanism—not only controls valve opening and closing but also provides sealing to protect against corrosion and fluid impact. Once cracks or defects develop, the risk of valve stem failure increases significantly, potentially compromising the operational safety of the entire nuclear power plant. To prevent future failures and ensure the safe, stable operation of nuclear power facilities, comprehensive inspections of similar globe valve types are essential. Early detection of defects and potential hazards is critical for safety. The valve stem analyzed in this study is commonly used in manual globe valves throughout nuclear power plants. Figure 1 illustrates the valve structure, with the stem—highlighted in red—manufactured from either carbon steel or precipitation-hardened martensitic stainless steel, the latter strengthened by secondary phase precipitation within the martensitic matrix. Valve stem diameters range from 10 to 30 mm, while handwheel diameters vary between 300 and 600 mm. The handwheel is threaded onto the valve stem, and an anti-rotation device ensures that the stem’s rotary motion is converted into vertical lifting or lowering, enabling precise valve actuation control.

Figure 1. Manual globe valve structure used in nuclear power plants

2. Analysis of Valve Stem Fracture Causes in Nuclear Power Plants

Through comprehensive analysis of valve stem fractures in operating nuclear power units, the primary causes of stem failure have been identified as follows:

Inadequate Mechanical Properties: Certain valve stem materials do not meet standard mechanical property requirements, showing susceptibility to hydrogen embrittlement and poor surface finish quality, which increases the risk of crack initiation under operational stress.

Improper Heat Treatment: Inadequate control of the heat treatment process causes grain boundary coarsening, resulting in decreased plasticity and corrosion resistance, thereby increasing susceptibility to intergranular corrosion.

High Stress Concentration at Machined Grooves: The sharp right-angle transition at the valve stem’s back-cut groove creates significant stress concentration, which greatly increases the risk of crack initiation and propagation.

Seawater-Induced Corrosion: Exposure to seawater causes pitting and intergranular corrosion on the valve stem, significantly accelerating material degradation and increasing the risk of failure.

These factors, individually or combined, contribute to the development of micro-cracks within the valve stem, which gradually propagate under external stresses and eventually cause complete fracture. Most fractures occur at the root of the valve stem, located inside the valve body and hidden from visual inspection; therefore, valve disassembly is required during each maintenance cycle to detect such fractures, as shown in Figure 2.

Figure 2. Fractured Valve Stem Embedded in the Valve Body

The main mechanical loads acting on the globe valve stem include impact forces from fluid flow during system startup and shutdown, shear forces during valve operation, and various external environmental stresses. The valve stem features an anti-rotation mechanism that restricts movement to linear (up-and-down) motion, with torque applied mainly to the upper stem near the rotary mechanism and axial forces concentrated in the threaded section. Notably, the second and third threads of the valve stem are common stress concentration areas, making them particularly vulnerable to fatigue failure. The axial force below the valve stem packing is mainly converted into frictional resistance by the packing seal, resulting in tensile stress on the stem that is well below the material’s allowable limit, ensuring normal valve operation does not cause stem breakage. Microcracks in valve stems are mainly caused by prolonged exposure to corrosive media during service; thus, developing online detection technology should focus on the valve’s actual loading conditions and failure mechanisms.

2. Test Method

The online detection of microcracks in globe valve stems is affected by various factors such as material properties, structural design, valve specifications, operational stress conditions, and the accessibility of inspection points on-site. In this study, non-destructive ultrasonic testing (UT) technology was employed to develop an effective online aging detection method for microcracks, focusing on the accessible sections of valve stems in nuclear power plants.

As shown in Figure 3, two specific areas of the valve stem are suitable for microcrack detection:

- Longitudinal wave fan scanning on the valve stem’s end face

- Transverse (shear) wave fan scanning on the cylindrical surface of the valve stem

The valve stem tested in this study measures 12 mm in diameter and 200 mm in length. Its complex structure, featuring a stop pin hole and a drilled threaded end face, causes significant attenuation of ultrasonic wave propagation due to the small diameter of the end face. Additionally, current probe manufacturing technologies do not achieve the precision required for effective end-face ultrasonic scanning. Therefore, end-face detection (Method 1) is unsuitable for this specific globe valve stem. Instead, aging detection is performed by scanning the cylindrical surface of the valve stem (Method 2), enabling inspection without fully disassembling the valve—only loosening the packing gland and pressure sleeve is required. Notably, the back seat region of the valve stem is the most failure-prone area, located deep inside the valve body and inaccessible to visual inspection; detecting defects here enables comprehensive microcrack monitoring throughout the entire valve stem.

Figure 3: Detectable Areas of the Valve Stem for Microcrack Inspection

The distance from the external surface of the valve stem to the back seat ranges between 50 mm and 100 mm. Due to the cylindrical shape of the valve stem, conventional straight-beam ultrasonic probes are ineffective for defect detection. Therefore, phased array ultrasonic testing (PAUT) with fan-shaped scanning is employed to achieve comprehensive defect detection. This advanced technique employs software-controlled phased array transducers to emit and receive ultrasonic waves, dynamically adjusting the phase delay of each array element to generate focused and angled sound beams for accurate internal flaw detection. A phased array probe comprises multiple small elements, each independently controlled, allowing the generation of multiple dynamic sound fields that provide broader detection coverage and improved accuracy compared to traditional single-element probes. During inspection, the probe stays stationary while software-controlled adjustments generate the necessary sound beam angles for comprehensive defect detection. Real-time imaging enables instant visualization of defects, making this method especially effective for detecting flaws in hard-to-reach areas such as the reverse sealing surface. In conclusion, this study identifies Method 2—transverse wave fan scanning on the valve stem’s cylindrical surface—as the most effective technique for online microcrack aging detection in globe valve stems.

2.1 Detection Device Design

Given the slender structure of the valve stem, ensuring effective ultrasonic penetration is a key factor in designing the detection device. Two key factors influencing ultrasonic penetration are the effective probe area and the chosen probe frequency; therefore, optimizing the phased array ultrasonic probe is essential for achieving accurate detection results. Considering the valve stem specifications, available on-site space, probe scanning position, required waveform characteristics, and angle range, a probe frequency of 7.5 MHz was selected for optimal detection performance. This frequency optimally balances penetration depth and high-resolution detection, enabling effective identification of small microcracks while maintaining a strong signal-to-noise ratio. A custom wedge was designed to ensure optimal coupling between the ultrasonic probe and the curved surface of the valve stem for accurate defect detection. The detection method utilizes shear wave fan scanning, with beam modeling and sound field simulation used to calibrate the probe setup, ensuring full coverage of the valve stem’s target detection area (Area B).

2.2 Test Specimen Design

To guarantee material consistency and structural accuracy, test specimens were fabricated using both new spare valve stems and disassembled in-service stems identical to those in actual operation, replicating the back seat (inverted seal) area where cracks most commonly develop. To simulate microcrack defects, electric discharge machining (EDM) created a narrow rectangular groove in the inverted seal area, measuring 1 mm deep and 0.2 mm wide, effectively mimicking early-stage valve stem cracks. Because ultrasonic waves reflect differently at various angles within the valve stem, multiple echo signals can appear for a single defect; therefore, only one artificial flaw was introduced per test specimen to prevent signal overlap and ensure accurate detection. Additionally, two valve stems with naturally occurring corrosion defects in the inverted seal area were tested to compare and verify the detection system’s capability to differentiate between corrosion damage and genuine microcrack defects, further confirming the method’s reliability.

2.3 Development of the Detection Method

To assess the ultrasonic phased array beam’s accessibility for detecting microcracks, phased array probes were tested on both new spare valve stems and recently disassembled valve stems. The testing process involved disassembling the valve, introducing simulated defects, and reassembling it, followed by assessing structural signals with the probe positioned 50 mm and 100 mm from the inverted seal (back seat). The feasibility of in-situ phased array ultrasonic testing was evaluated by analyzing the reflection amplitude and signal-to-noise ratio of the structural echo signals.

The results confirmed that high-resolution signals with clear structural characteristics were observed at 50 mm, 80 mm, and 100 mm from the inverted seal. At these distances, the structural signals were clearly distinguishable, with no interference impacting the accurate interpretation of defects. Based on these findings, the optimized detection zone was established at 100 mm from the overtravel groove, and a tailored detection procedure was developed accordingly. Based on theoretical calculations of the required beam coverage, the phased array probe was positioned 100 mm from the overtravel groove and linearly scanned along the valve stem’s circumference to identify the maximum signal response from reflectors. During scanning, the probe remains stationary along the axial direction, eliminating the need for forward or backward movement, while the instrument gain is adjusted to achieve a signal height of 80% full screen height (FSH). A reference test block is scanned under identical conditions, adjusting the strongest echo from the artificial defect to 80% full screen height (FSH), and the corresponding gain value is recorded for calibration. This step ensures consistent, repeatable sensitivity calibration, enabling accurate and reliable defect detection during actual inspections.

3. Results and Discussion

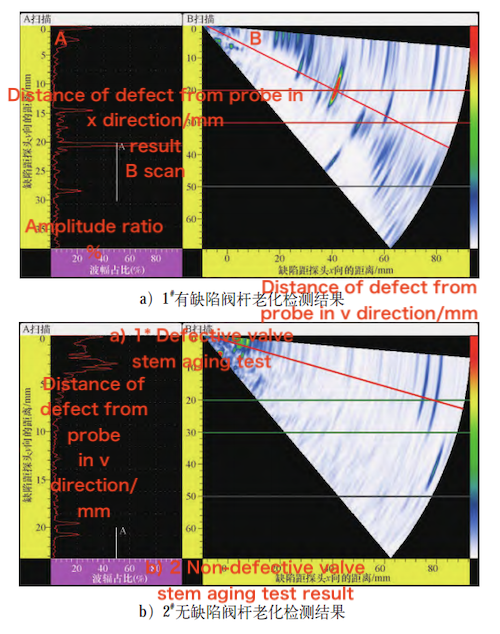

To validate the effectiveness of the proposed microcrack aging detection technology, this study tested seven different types of globe valve stems, as illustrated in Figure 4, with detailed specifications provided in Table 1. A specially designed phased array ultrasonic probe, optimized for electrical and acoustic performance, was selected for aging detection based on the unique structural characteristics of each valve stem. Paired with a portable phased array detection system, this setup provided comprehensive coverage of the entire valve stem surface. Samples 1' and 2' have identical materials and dimensions; Sample 1' was artificially modified to include simulated crack defects, whereas Sample 2' served as the defect-free control. Both samples underwent aging detection, with results clearly showing that the system successfully identified cracks in Sample 1', while Sample 2' exhibited no defects (see Figure 5).

Figure 4. Sample Numbers of Valve Stems

Table 1. Specifications of Tested Valve Stems

|

Sample |

Material |

Diameter (mm) |

Length (mm) |

Distance to Inverted Seal (mm) |

Additional Notes |

|

1' |

Stainless steel |

16 |

230 |

77.3 |

Artificial defects added |

|

2' |

Stainless steel |

16 |

230 |

77.3 |

No defects |

|

3' |

Stainless steel |

21 |

235 |

90 |

|

|

4' |

Stainless steel |

13 |

210 |

70 |

|

|

5' |

Stainless steel |

13 |

150 |

70 |

|

|

6' |

Carbon steel |

13 |

200 |

No visible defects |

No corrosion or holes |

|

7' |

Carbon steel |

13 |

200 |

150 |

Corrosion defects present |

Figure 5. Comparison of Aging Test Results

a) Aging Test Results of Defective Valve Stem (Sample 1') b) Aging Test Results of Defect-Free Valve Stem (Sample 2')

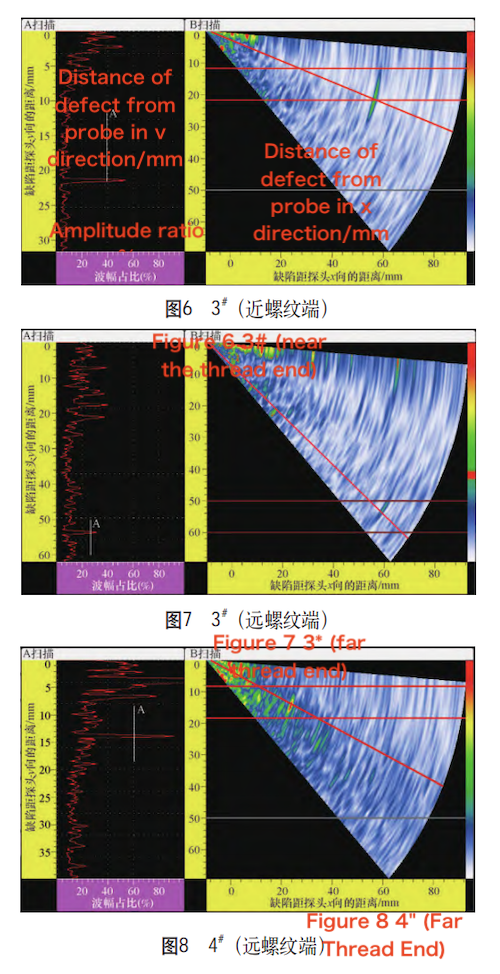

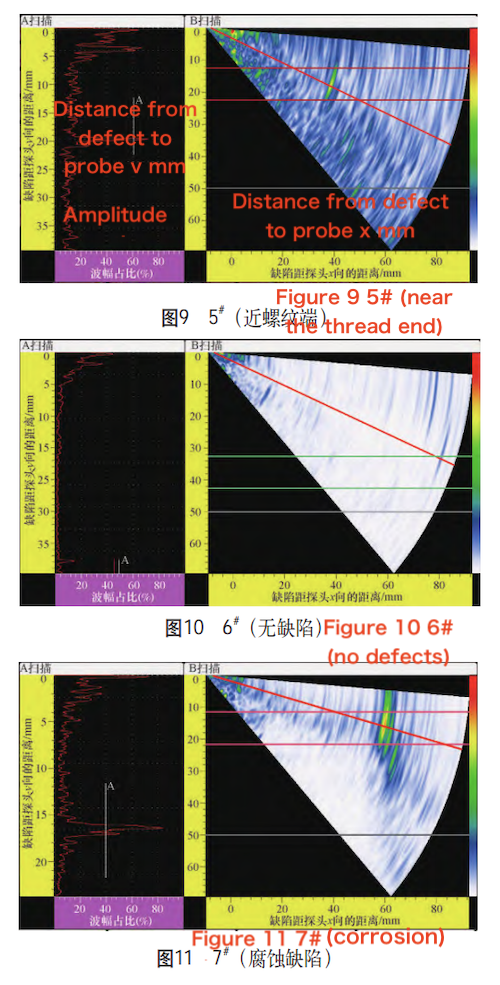

Additionally, aging detection was performed on other valve stem samples, with defect detection results summarized in Table 2.

Table 2. Aging Detection Results for All Valve Stem Samples

|

Sample & Location |

Result (See Figure) |

Evaluation Summary |

|

3' (near thread end) |

Figure 6 |

Clear signal, and accurately detects actual defects |

|

3' (far thread end) |

Figure 7 |

Detection energy sufficient, and iron sink clearly visible |

|

4' (far thread end) |

Figure 8 |

High detection clarity, and defect easily identified |

|

5' (near thread end) |

Figure 9 |

Clear signal, aligns with real defect conditions |

|

6' (no defects) |

Figure 10 |

Clean detection interface; no false signals |

|

7' (corrosion defect) |

Figure 11 |

Iron sink clearly displayed, but crack and corrosion are not distinguishable. |

Figures 6–8: Ultrasonic Scans of Valve Stem Samples

Figure 6: Sample 3' (near thread end) – Defect clearly detected

Figure 7: Sample 3' (far thread end)

Figure 8: Sample 4' (far thread end)

Figures 9–11: Ultrasonic Scans of Valve Stem Samples

Figure 9: Sample 5' (near thread end)

Figure 10: Sample 6' (defect-free) – No abnormalities detected

Figure 11: Sample 7' (corrosion defect) – Iron deposits visible; defect type unclear

Key Findings

Reliable Detection Performance:

The aging detection results accurately correspond to the known conditions of each valve stem, effectively identifying microcrack defects with clear and stable ultrasonic signals.

Detection Efficiency by Location:

Defect detection sensitivity is higher near the thread end compared to the far end, indicating that shorter stem lengths or closer proximity to the probe improve detection accuracy.

Defect Identification Limitation:

While this method reliably detects the presence of defects, it cannot differentiate between defect types such as microcracks and corrosion pits, necessitating additional diagnostic techniques for precise classification.

4. Conclusion

Considering the practical challenges of globe valve stem maintenance and replacement in field service environments, a specialized aging detection technology for microcracks in globe valve stems has been developed to improve inspection efficiency and reliability. This technology effectively detects microcracks in critical fracture-prone areas of the valve stem, significantly reducing maintenance workload. It enables online, non-disassembly inspection of internal defects throughout the entire valve stem, improving safety and operational efficiency. This study provides a preliminary feasibility analysis of valve stem aging detection technology. Future research will develop specialized detection procedures for different defect types and establish precise criteria to ensure accurate detection across various valve stem models. With continuous advancements in precision manufacturing and chip processing technologies, valve stem microcrack aging detection will advance further, enabling large-scale, high-accuracy detection of microcracks in globe valve stems used in nuclear power plants.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

The Composition of Spring Micro Open Safety Valve

- Jul 07, 2015

Flexible Micro Robot Arm

- Jul 14, 2020

Related Products Mentioned in the Article

Supplier Website

Source: https://www.baltic-valve.com/micro-crack-aging-detection-technology-for-globe-valve-stems-in-nuclear-power-applications.html