Impact of Disc Springs on Ball Valve Performance

Abstract

When designing ball valves—especially trunnion-mounted ball valves—disc springs play a critical role in determining overall performance. Disc springs primarily provide sealing and preload. Inadequate sealing performance can compromise the quality and service life of a ball valve, making it difficult to meet design and operational requirements. Therefore, designers must carefully verify disc spring materials and design parameters to ensure they meet the intended service life. This article analyzes the key impact of disc spring performance on ball valve operation and explores their fatigue and lifespan characteristics, offering practical insights and guidance for professionals in the field.

Introduction

Although small in size, disc springs play a crucial role in ball valve performance. They directly influence both sealing effectiveness and operating torque during opening and closing. Sealing is a critical factor in ball valve selection: effective sealing not only enhances reliability but also strengthens market competitiveness, while opening and closing torque has a direct impact on valve actuation. Consequently, when designing a ball valve, engineers should select disc spring materials suited to the intended operating conditions and optimize the design to minimize the risk of leakage.

1. The Main Impact of Disc Spring Performance on Ball Valves

1.1 Preload Force Calculation

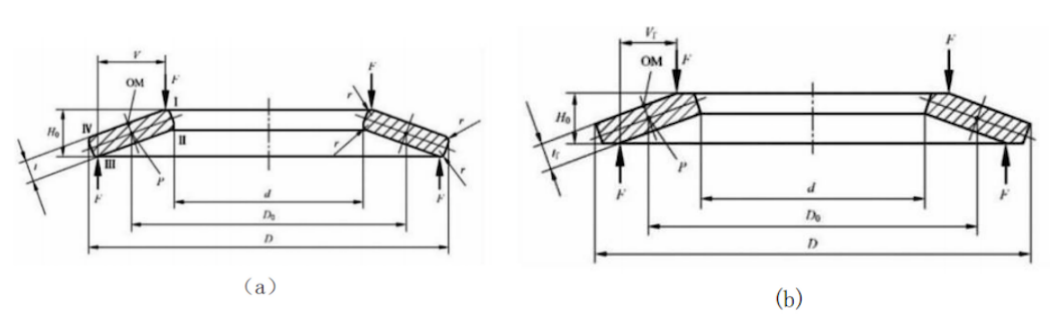

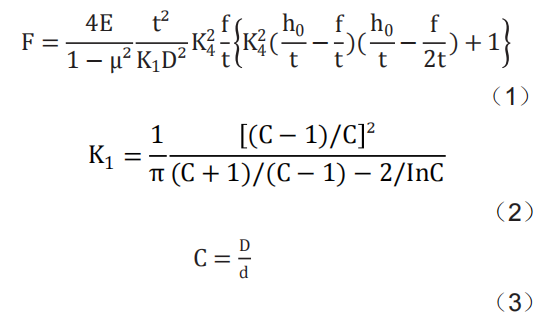

Calculating preload force is a critical step in disc spring design and a fundamental parameter in ball valve engineering, as it ensures reliable valve performance under a wide range of operating conditions. Designers should carefully calculate the disc spring preload force based on the ball valve’s design parameters, since the preload directly governs overall sealing performance. The preload generates the contact force between the ball and the valve seat, ensures stable operation of both components, and prevents leakage or abnormal flow of the medium. The calculation of disc spring preload should consider the material thickness and is generally carried out using two design methods, as illustrated in Figure 1. For disc springs without a support surface, the thickness should be ≤6 mm, while for disc springs with a support surface, the thickness should exceed 6 mm. When designing the overall ball valve structure, internal components should be optimized based on the disc spring’s required preload, calculated using formulas (1), (2), and (3).

Figure 1. Schematic of disc springs: (a) without a support surface, (b) with a support surface

In the above formulas:

F represents the load of a single disc spring;

E is the elastic modulus;

H is Poisson’s ratio;

t is the disc spring thickness;

K is the calculation coefficient;

D and d are the outer and inner diameters of the disc spring, respectively.

f is the deformation of a single disc spring;

h is the flattening deformation of the disc spring;

C is the diameter ratio.

Observations of the ball valve disc spring reveal that, although its overall shape is relatively simple, it embodies a unique design concept—specifically, providing a large preload force with minimal deformation, a function that conventional coil springs cannot achieve.

2. Applicability of Material Selection

As noted above, disc springs are critical components that significantly influence the performance of ball valve designs. Designers should account for the behavior of disc springs under various operating conditions, especially in high- or low-temperature environments. Common materials include nickel-based alloys, cobalt-based alloys, stainless steel, and titanium alloys, each chosen according to the ball valve’s specific operating environment.

(1) Nickel-Based Alloys

When selecting disc spring materials, designers must carefully consider the elastic modulus and material strength requirements. Suitable options include nickel-chromium alloys and nickel-copper alloys. Both alloys provide excellent high-temperature resistance, ensuring the stability of disc springs under elevated operating conditions. Additionally, nickel-chromium alloys are well-suited for ball valves handling corrosive media, especially oxidizing acidic environments, whereas nickel-copper alloys are primarily used in high-salinity media and also offer excellent high-temperature resistance.

(2) Stainless Steel

Considering the demanding operating conditions of ball valves, disc springs must exhibit excellent corrosion resistance, which stainless steel reliably provides. Designers typically choose 304 or 316 stainless steel for disc springs. However, in high-temperature applications, alternative materials should be considered, as the strength and elasticity of stainless steel can vary significantly under elevated temperatures.

(3) Cobalt-Based Alloys

Cobalt-based alloys are primarily used in applications involving high-temperature media or media that cause significant wear. These alloys remain stable at high temperatures, with hardness and strength sufficient to meet operational requirements. A commonly used cobalt-based alloy is Stellite, although its high cost limits its use in disc spring design.

(4) Titanium Alloys

Titanium alloys offer high strength, excellent corrosion resistance, and reduced weight for disc springs. They are primarily used for transporting highly corrosive media, with Ti-6Al-4V being the main grade. Analysis of these materials indicates that designers must carefully consider the specific application of the ball valve, balancing design requirements, operating conditions, and manufacturing costs. After selecting the material, professional testing should be conducted to simulate real operating conditions. Additionally, cost is an important factor to consider when choosing disc spring materials. For ball valves not intended for specialized applications, nickel-based and titanium alloys are generally avoided because of their high material costs and the requirement for specialized processing equipment. Therefore, designers should carefully select disc spring materials to minimize material and processing costs while ensuring product quality and performance are not compromised.

1.3 Performance Research

High-temperature resistance is a critical factor in evaluating the design quality of ball valves. As critical components exposed to high-temperature environments, disc springs require designers to integrate comprehensive data and apply precise, scientific design methods. As noted earlier, nickel-based alloys provide excellent high-temperature and corrosion resistance, although their production costs are relatively high. The primary reason high temperatures impact disc spring performance is the reduction in the material’s elastic modulus, which lowers the spring’s elasticity and undermines the ball valve’s sealing performance. This can lead to the need for valve replacement, directly affecting operational reliability. Studies on nickel-based alloys have demonstrated that these materials maintain excellent elasticity at temperatures ranging from 200 °C to 1000 °C, even surpassing the performance of Inconel 625. The material’s elastic modulus remains stable under high-temperature conditions, with experiments showing values up to 190 GPa, confirming its suitability for most disc spring applications in high-temperature ball valves. Thermal expansion also directly influences disc spring performance, as different materials undergo significant dimensional changes at elevated temperatures. Due to their relatively low thermal expansion, nickel-based alloys are therefore the preferred choice for disc springs in high-temperature ball valves. Accordingly, when selecting disc spring materials, designers should give priority to nickel-based or cobalt-based alloys. These materials can effectively extend the service life of ball valves, but processing techniques must be optimized to ensure that the disc spring meets the demands of high-temperature environments.

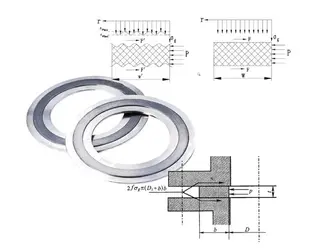

1.4 Advantages of a Combination Design

In some ball valve applications, a single-disc spring design may be insufficient to meet specific environmental requirements. Designers must choose suitable materials and configurations according to the intended operating environment. A combined disc spring design can significantly improve ball valve performance. By arranging multiple disc springs in series, designers can take advantage of the unique characteristics of each spring. This approach satisfies the requirements of ball valves in diverse operating environments, preventing situations where a single disc spring would be insufficient. The combined disc spring design enhances sealing performance and extends the operational life of the ball valve, reducing the need for frequent replacements and lowering design and manufacturing costs, thereby improving product competitiveness. Because ball valves often open and close to meet media flow requirements, a single disc spring may experience excessive wear, resulting in reduced sealing and potential leakage. Using multiple disc springs in combination reduces the load on each individual spring, ensuring that the ball valve continues to operate normally even if one spring experiences wear. Designers should also take high-temperature operating conditions into account and optimize the internal valve structure based on the disc springs’ high-temperature resistance.

1.5 Other Functional Research

Disc springs primarily serve a sealing function in ball valve design. They are primarily positioned in the valve seat area, providing the necessary preload for proper operation. In conjunction with other components, they help extend the valve’s service life and improve overall performance. During life testing of the ball valve, incorporating disc springs into the stem packing enabled the valve to complete approximately 15,000 cycles. Under similar conditions without disc springs in the stem packing, the valve achieved only around 3,000 cycles. These results demonstrate that disc springs have a substantial impact on ball valve lifespan. Furthermore, this experiment did not consider sealing performance under high-temperature conditions; including such conditions would likely have produced even more pronounced differences.

2. Research on Disc Spring Fatigue and Life Characteristics

2.1 Factors Affecting Disc Spring Fatigue Life

The primary factors influencing the fatigue life of disc springs are material properties, manufacturing processes, operating conditions, and applied loads. These factors have a significant impact on the fatigue behavior of disc springs, and designers must perform targeted testing based on the ball valve’s specific operating conditions. Material selection is critical; the chosen material must possess high strength, toughness, and hardness. Designers should also evaluate the material’s microstructure and consider the performance characteristics of different materials, prioritizing those with high fatigue strength to maximize the disc spring’s service life. Manufacturing technology is another critical factor. Surface roughness, residual stress, and the presence of notches or grooves can significantly influence fatigue performance. Excessive surface roughness, for example, can accelerate fatigue failure. Therefore, designers should optimize manufacturing processes to enhance surface smoothness and minimize stress concentrations. Operating conditions, including temperature and media characteristics, also impact fatigue life. Prolonged exposure to high temperatures can cause the same disc spring material to exhibit varying degrees of fatigue. High operating loads accelerate fatigue, and harsh conditions can cause damage that compromises normal valve performance. Designers should also take into account the operating pressure and the frequency of start-stop cycles. Larger-diameter valves demand higher disc spring strength, and frequent start-stop cycles within short intervals should be carefully controlled to avoid premature fatigue.

2.2 Disc Spring Life Calculation Methods

Failure of the disc spring can reduce the sealing performance of the ball valve and, in severe cases, cause the valve to lose functionality, potentially disrupting media transportation. Disc spring failure can reduce the sealing performance of a ball valve and, in severe cases, lead to complete loss of functionality, potentially disrupting media transport. Three common methods are used to calculate disc spring life: the S–N curve method, crack propagation theory, and finite element analysis (FEA) prediction.”

(1)S-N Curve Method

The S–N curve, also referred to as the stress–life curve, is derived from stress data of different disc spring materials under varying operating conditions. By testing under these conditions, the fatigue life of the disc spring can be determined. Since stress and strain levels are directly related to fatigue life, S–N and strain–life curves provide effective means of predicting fatigue performance under different loads.

(2) Crack Propagation Theory

The crack propagation method estimates fatigue life using the Paris law, taking into account crack growth under different loading conditions. This approach incorporates the fatigue resistance characteristics of the disc spring material. Targeted calculations under varying load conditions can yield accurate fatigue life data for the spring. The specific calculation formula is as follows:

In this formula:

ΔK represents the stress intensity factor range at the crack tip;

C and m are material-specific parameters of the disc spring.

(3) Finite Element Prediction Method

With advances in information technology, designers can now use finite element analysis (FEA) to predict the fatigue life of disc springs. A finite element model is constructed to simulate the spring’s behavior under various loading conditions, enabling analysis of stress and damage. Large-scale data collection enhances both the efficiency and accuracy of fatigue life predictions. However, processing methods and material defects must also be taken into account. By considering these factors comprehensively, designers can effectively optimize the service life of the ball valve.

2.3 Effective Measures to Improve Disc Spring Fatigue Life

Extending the fatigue life of disc springs can significantly improve the performance of ball valves. Designers should select disc spring materials carefully, based on the valve’s specific operating conditions. Processing techniques should be optimized to minimize defects, and surface treatments should be applied according to the properties of the selected materials. Additionally, the overall design of the ball valve should be optimized to eliminate stress concentrations, thereby enhancing performance and durability.

3. Conclusion

In summary, disc springs are a critical component of ball valve design, and operating conditions significantly influence their service life. Designers should adopt a systematic design strategy, selecting disc spring materials that offer high-temperature resistance, corrosion resistance, and adequate strength. Applying targeted processing techniques and accurately calculating disc spring fatigue life provides a solid foundation for designing high-quality, reliable ball valves.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.baltic-valve.com/impact-of-disc-springs-on-ball-valve-performance.html

.png)