Industry Definition & Scope

The welded neck flanges industry comprises the design, manufacturing, and application of flanges characterized by a long tapered hub that is butt-welded to piping systems, providing superior strength, leak integrity, and stress distribution in high-pressure, high-temperature, and critical service applications. As premium connection components, they are essential in industries where safety, reliability, and long-term performance are paramount.

Key Product Categories

-

By Design Specifications:

-

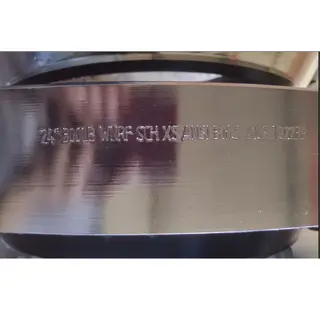

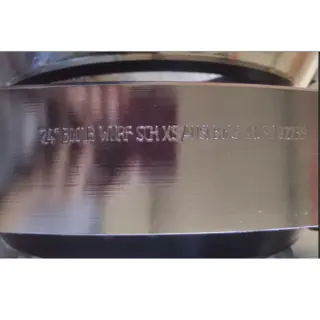

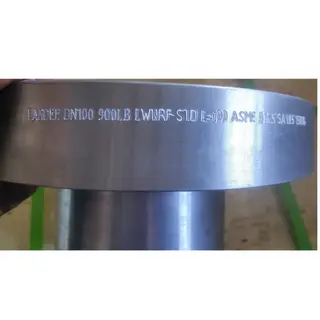

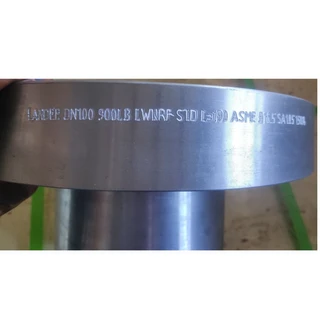

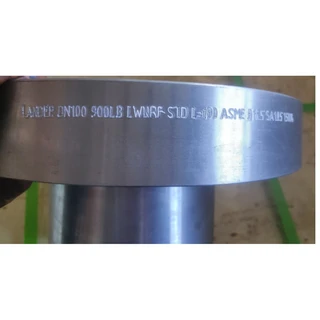

Standard Welded Neck Flanges: ANSI/ASME B16.5, B16.47 Series A & B

-

Long Welding Neck (LWN) Flanges: Extended hub for vessel nozzles and heat exchangers

-

Special Hub Designs: Heavy barrel, extra heavy, and custom tapered geometries

-

Integral Flanges: Forged as one piece with piping or equipment nozzles

-

-

By Pressure Class:

-

ANSI Classes: 150, 300, 600, 900, 1500, 2500

-

PN Ratings: PN6 to PN400 (EN 1092-1, DIN standards)

-

High-Pressure Specials: For hydraulic, thermal, and nuclear applications

-

-

By Material Grades:

-

Carbon Steel: ASTM A105, A350 LF2, A694 F52/F60/F65

-

Stainless Steel: ASTM A182 F304/304L, F316/316L, F321, F347

-

Alloy Steel: ASTM A182 F11, F22, F91, F92

-

Nickel Alloys: Monel, Inconel, Hastelloy, Incoloy

-

Duplex/Super Duplex: UNS S31803, S32750, S32760

-

-

By End-Facing Types:

-

Raised Face (RF): Standard for gasket seating

-

Flat Face (FF): Full-face gasket applications

-

Ring-Type Joint (RTJ): High-pressure metal seal

-

Tongue & Groove (T&G): Precision alignment applications

-

Male & Female (M&F): Recessed seal applications

-

-

By Application Focus:

-

Oil & Gas: Pipeline, refinery, offshore platforms (API 6A, NACE MR0175)

-

Power Generation: Boiler connections, steam lines, turbine piping

-

Chemical & Petrochemical: Reactor nozzles, high-pressure process lines

-

Nuclear Industry: RCC-M, ASME Section III Class 1, 2, 3

-

Water & Wastewater: High-pressure pumping and transmission systems

-

Technology & Innovation Trends

-

Advanced Manufacturing:

-

Closed-die forging with precision CNC machining

-

Robotic welding preparation and weld overlay automation

-

Non-destructive testing (RT, UT, PT, MT) integration in production lines

-

Heat treatment tracking with IoT-enabled furnace controls

-

-

Material & Coating Technology:

-

Corrosion-resistant alloy (CRA) weld overlays (Inconel 625, Stellite)

-

Internal lining systems for corrosive service

-

High-temperature oxidation-resistant coatings

-

Cryogenic material treatments for LNG applications

-

-

Digital Integration:

-

QR code/RFID traceability from forging to installation

-

Digital twin integration for stress analysis and fatigue life prediction

-

Automated weld procedure qualification and documentation

-

Cloud-based flange management systems

-

-

Sustainability & Efficiency:

-

Lightweight optimized designs reducing material usage

-

Energy-efficient forging and heat treatment processes

-

Recycling programs for flange reconditioning and reuse

-

Low-emission manufacturing technologies

-

Global Market Drivers

-

Expansion of high-pressure oil & gas pipelines and LNG terminals

-

Power plant upgrades and new nuclear/thermal plant construction

-

Petrochemical industry capacity additions in Asia and Middle East

-

Renewable energy projects (hydrogen pipelines, geothermal, CCUS)

-

Stringent safety and emission regulations (ISO 15848, API 6A)

-

Infrastructure replacement in aging industrial plants

-

Offshore wind farm installation and subsea applications

Major Players & Value Chain

-

Global Forging Specialists: FLOWSERVE, IMI Critical Engineering, Pro-Flange, Texas Flange

-

Integrated Steel & Forging Groups: Nippon Steel, JSW, Bharat Forge, China Baowu

-

Regional Leaders: India (Rashmi Group, Metal Forgings), China (Jiangsu Sheye, Zhongke)

-

Specialty Alloy Suppliers: Carpenter Technology, VDMA, Special Metals

-

Value Chain: Steel alloy production → forging → machining → heat treatment → testing/certification → distribution → fabrication/welding → end-user

Challenges & Opportunities

-

Challenges:

-

High capital intensity and long production lead times

-

Skilled labor shortage in forging and welding trades

-

Raw material price volatility (alloying elements)

-

Competition from alternative connection methods

-

Complex certification requirements for nuclear/aerospace

-

-

Opportunities:

-

Hydrogen economy infrastructure development

-

Digital flange lifecycle management services

-

Additive manufacturing for complex geometries

-

Offshore and subsea market expansion

-

Aftermarket services: re-machining, weld repair, re-certification

-

Emerging market energy infrastructure growth

-