Industry Definition & Scope

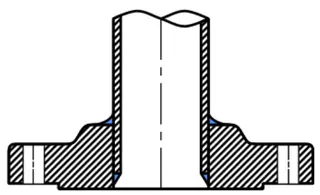

The slip-on flanges industry involves the design, manufacturing, and application of pipe flanges characterized by a bore slightly larger than the pipe's outer diameter, allowing them to "slip over" the pipe before being fillet-welded both inside and outside. As one of the most common and cost-effective flange types, they are widely used in low-to-medium pressure applications across process industries, HVAC, water systems, and general piping networks where easy alignment and installation efficiency are prioritized.

Key Product Categories

-

By Design Specifications:

-

Standard Slip-On Flanges: ANSI/ASME B16.5, B16.47 Series A & B

-

Reducing Slip-On Flanges: For connecting pipes of different diameters

-

Slip-On Blind Flanges: Solid disc design for temporary or permanent system closure

-

Threaded Slip-On Flanges: Combined slip-on and threaded connection features

-

Raised Face (RF) & Flat Face (FF) Designs: For gasket compatibility

-

-

By Pressure Class:

-

ANSI Classes: 150, 300, 600 (most common), limited use in 900+

-

PN Ratings: PN6 to PN40 (EN 1092-1, DIN 2576)

-

Special Classes: For specific industry standards (AWWA, MSS)

-

-

By Material Grades:

-

Carbon Steel: ASTM A105, A350 LF2

-

Stainless Steel: ASTM A182 F304/304L, F316/316L

-

Alloy Steel: ASTM A182 F11, F22 (limited high-temp applications)

-

Ductile Iron: ASTM A536

-

Non-Ferrous: Bronze, Brass, Aluminum

-

Coated Variants: Galvanized, epoxy-coated for corrosion protection

-

-

By Application Focus:

-

Process Piping: Chemical, pharmaceutical, food & beverage

-

HVAC Systems: Chilled water, heating, ventilation ducts

-

Water Infrastructure: Potable water, wastewater, irrigation

-

Oil & Gas (Low Pressure): Vent lines, drain systems, auxiliary piping

-

Power Generation (Auxiliary Systems): Cooling water, lubricating oil lines

-

Marine & Shipbuilding: Low-pressure seawater and ballast systems

-

Technology & Innovation Trends

-

Advanced Manufacturing Techniques:

-

Laser and plasma cutting for precise bore and face machining

-

Automated fillet welding systems with consistent weld profiles

-

CNC machining for improved flange face flatness and finish

-

Robotic drilling for accurate bolt hole alignment

-

-

Material & Coating Innovations:

-

Hybrid materials with clad surfaces for corrosion resistance

-

Powder-coated and polymer-lined flanges for chemical service

-

Bio-based coatings for environmentally sensitive applications

-

Nano-coatings for enhanced durability in humid environments

-

-

Digital Integration:

-

QR code/RFID tagging for installation and maintenance tracking

-

BIM (Building Information Modeling) compatibility in construction

-

Digital weld procedure documentation and traceability

-

IoT-enabled flange monitoring for leak detection

-

-

Sustainability & Efficiency:

-

Lightweight designs reducing material consumption

-

Optimized welding procedures minimizing heat distortion

-

Recyclable material usage and production waste reduction

-

Energy-efficient manufacturing through induction heating

-

Global Market Drivers

-

Expansion of water and wastewater treatment infrastructure

-

Growth in HVAC installations in commercial and residential construction

-

Industrial plant maintenance and retrofit projects

-

Food processing and pharmaceutical industry hygiene standards

-

Renewable energy projects (biogas, geothermal low-pressure systems)

-

Urbanization driving utility pipeline networks

-

Cost optimization in non-critical piping applications

Major Players & Value Chain

-

Global Flange Specialists: Pro-Flange, Texas Flange, Metal Udyog, Flange Guard

-

Integrated Steel & Forging Groups: Nippon Steel, JSW, China Baowu, ArcelorMittal

-

Regional Manufacturers: India (Rashmi Group), China (Zhejiang, Jiangsu clusters), Southeast Asia

-

Distributor Networks: Fastenal, Würth, MSC Industrial Supply

-

Value Chain: Steel production → forging/plate cutting → machining → welding preparation → coating → quality testing → distribution → fabrication contractors → end-users

Challenges & Opportunities

-

Challenges:

-

Limited pressure and temperature ratings compared to weld neck flanges

-

Weld quality dependency for structural integrity

-

Competition from plastic and composite piping systems

-

Price sensitivity in standardized product segments

-

Corrosion susceptibility in improper material selections

-

-

Opportunities:

-

Modular construction and prefabricated piping systems

-

Smart city infrastructure and utility network expansion

-

Digital inventory and just-in-time delivery models

-

Retrofitting programs for aging water and HVAC systems

-

Emerging market urbanization and industrial park development

-

Customized solutions for specialized low-pressure applications

-