1. Industry Definition & Scope

The Refrigeration & Heat Exchange Equipment industry involves the design, manufacture, sale, and maintenance of machinery and system equipment used for heat transfer, temperature control, and energy recovery. Serving as the modern industrial and commercial "temperature regulator" and "energy mover," its core function is to absorb heat from a low-temperature source and reject it to a high-temperature source through refrigeration cycles and heat exchange principles. It is widely applied in comfort air conditioning, industrial refrigeration, cold chain logistics, data center cooling, process thermal management, and energy recovery.

2. Main Product Categories

1. Core Refrigeration System Equipment

-

Compressors: The "heart" of the refrigeration cycle.

-

Types: Reciprocating, screw, scroll, centrifugal.

-

Drive: Fixed-speed, variable-speed, magnetic bearing.

-

-

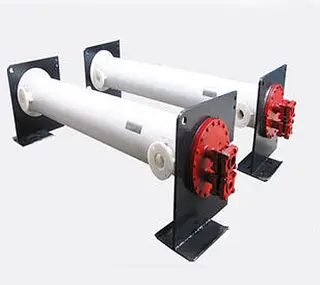

Condensers: Heat exchangers that condense refrigerant vapor into liquid.

-

Types: Water-cooled (shell & tube), air-cooled, evaporative.

-

-

Evaporators: Heat exchangers that absorb heat from the cooled medium.

-

Types: Dry-expansion, flooded, falling film, air cooling units.

-

-

Expansion Devices: Control refrigerant flow, creating a pressure drop.

-

Types: Thermostatic expansion valves (TXV), electronic expansion valves (EEV), capillary tubes, orifice plates.

-

-

Chillers/Refrigeration Units: Integrated packages combining the above components.

-

Chillers: Centrifugal, screw, scroll chillers.

-

Heat Pump Units: Capable of both cooling and heating.

-

2. Heat Exchange Equipment

-

By Heat Transfer Principle:

-

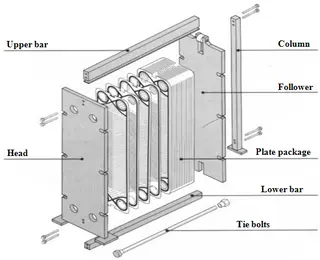

Recuperative (Indirect): Fluids separated by a solid wall, e.g., shell & tube, plate, plate-fin, double-pipe.

-

Direct-Contact: Fluids mix directly, e.g., cooling towers, spray chambers.

-

Regenerative: Hot and cold fluids alternately flow through a heat storage matrix, e.g., rotary air preheaters.

-

-

By Application:

-

Process Heat Exchangers: For heating/cooling process streams in petrochemical, pharmaceutical industries.

-

HVAC Heat Exchangers: Cooling/heating coils in fan coil units and air handling units.

-

Waste Heat Recovery Exchangers: Economizers, flue gas condensers, heat pipe exchangers.

-

3. End-Use Equipment & Systems

-

Comfort Air Conditioning: Variable Refrigerant Flow (VRF) systems, packaged units, rooftop units, residential split systems.

-

Commercial Refrigeration: Supermarket display cases, beverage coolers, ice cream cabinets.

-

Industrial Refrigeration: Cold storage warehouses, blast freezers, ice makers, industrial chillers.

-

Specialty Cooling Systems: Data center precision air conditioning, server liquid cooling, medical refrigeration, chip testing chillers.

-

Cooling Towers & Fluid Handling: Open/closed circuit cooling towers, pumps, water treatment systems.

4. Control Systems & Key Components

-

Control Systems: PLC/DDC controllers, BAS integration, IoT remote monitoring platforms.

-

Key Components: Four-way reversing valves, refrigerants, lubricants, filter-driers, pressure sensors, variable frequency drives (VFD).

3. Industry Chain Structure

Upstream:

-

Raw Materials: Copper tubes, aluminum fins, steel (plates, tubes), refrigerants (R32, R134a, R410A, CO₂, ammonia, etc.), compressor motors, control chips.

-

Core Component Suppliers: Compressors (e.g., Danfoss, Bitzer, Gree, Midea), enhanced heat transfer tubes (micro-fin, inner-grooved), micro-channel flat tubes, electronic expansion valves, controllers.

Midstream:

-

Equipment Manufacturers:

-

Vertically Integrated Giants: Companies covering compressors, heat exchangers, to complete units (e.g., Carrier, Trane, Johnson Controls, Daikin, Gree, Midea).

-

Specialized Component Makers: Focused on high-efficiency heat exchangers, specialty valves, etc.

-

System Integrators & Engineers: Design and integrate customized systems for specific projects (e.g., data centers, pharmaceutical plants).

-

-

Distributors & Dealers: Handle regional sales and logistics.

Downstream:

-

End-User Industries:

-

Building & Construction: Commercial complexes, hotels, hospitals, schools, residences.

-

Industrial Manufacturing: Chemicals, pharmaceuticals, food & beverage, electronics, automotive.

-

Cold Chain Logistics: Cold storage warehouses, refrigerated transport, retail.

-

Data Centers & Telecom: IT room cooling, base station thermal management.

-

Transportation: Automotive AC, rail & ship refrigeration.

-

-

Service Market: Installation, commissioning, maintenance, repair, retrofit, Energy Performance Contracting (EPC).

4. Core Industry Characteristics & Barriers

1. Energy Efficiency as Core Competitiveness

-

Stringent Efficiency Standards: Strict MEPS and energy labeling schemes globally.

-

Full-Load & Part-Load Efficiency: IPLV (Integrated Part Load Value) is increasingly important alongside full-load COP.

-

System Optimization: High efficiency stems from协同 optimization of compressors, heat exchangers, fans, and controls.

2. High Reliance on Technological Innovation

-

New Refrigerant Adoption: Acceleration of natural (CO₂, ammonia, hydrocarbons) and low-GWP refrigerant applications due to environmental regulations (HCFC phase-out, HFC controls).

-

Efficiency Enhancement Technologies: e.g., magnetic bearing compressors, falling film evaporation, micro-channel heat exchange, variable speed and capacity control.

-

Intelligent Control: AI-based load forecasting, optimized operation, fault diagnosis.

3. High Degree of Customization

-

Non-Standard Designs: Industrial and large commercial projects require customized design and integration based on site conditions and process needs.

-

Complex System Engineering: Involves matching heat source/sink, distribution systems, terminal units, and control systems.

4. Strong Safety & Environmental Regulation Drive

-

Pressure Equipment Codes: Some equipment falls under pressure vessel regulations.

-

Environmental Regulations: Driven by the Montreal Protocol and its Kigali Amendment, forcing refrigerant transition.

-

Building Energy Codes: Mandate the use of high-efficiency equipment and systems in design.

5. Development Trends

-

High Efficiency & Decarbonization

-

Continuous Efficiency Gains: Record-breaking COP/IPLV values approaching theoretical limits.

-

Natural Refrigerant Revival: CO₂ transcritical cycles in heat pump water heating and supermarkets; ammonia/hydrocarbons in industrial refrigeration.

-

Waste Heat Recovery & Energy Integration: Heat pumps for industrial waste heat upgrade, enabling combined cooling, heating, and power (CCHP).

-

-

Intelligentization & Digitalization

-

Smart Units: Embedded with intelligent control logic for adaptive adjustment and group optimization.

-

Digital Twin & Predictive Maintenance: Virtual models based on IoT data to predict faults and optimize maintenance schedules.

-

Cloud Platform Services: Providing remote monitoring, energy analytics, and asset management services.

-

-

Modularization & Integration

-

Integrated Plant Rooms: Prefabricated skids integrating chillers, pumps, valves, and controls to reduce on-site installation time.

-

Multi-Function Integrated Units: Combining cooling, heating, hot water, ventilation in one package.

-

-

Application Segmentation & Expansion

-

Data Center Liquid Cooling: Liquid cooling (cold plate, immersion) becoming critical as chip power density soars.

-

New Energy Vehicle Thermal Management: Surging demand for integrated thermal management systems for EV batteries, e-drive, and cabins.

-

Energy Storage Station Cooling: Growing need for precision temperature control in lithium battery energy storage systems.

-

6. Key Challenges & Opportunities

Challenges:

-

Rapid Technological Iteration: Requires continuous high R&D investment for new refrigerants and technologies.

-

Significant Cost Pressure: Volatile raw material (e.g., copper) prices, high cost of high-efficiency components, and intense market competition.

-

Professional Talent Shortage: Shortage of system design, commissioning, and service engineers/technicians.

-

Competition in Mature Markets: Slowing new demand in mature markets shifts competition to retrofit and service.

Opportunities:

-

Global Energy Transition & "Dual Carbon" Goals: The strongest driver for high-efficiency equipment and heat pump adoption.

-

Growth in New Markets & Segments: Emerging industries like data centers, EVs, biopharma creating new growth vectors.

-

Retrofit & Energy Service Market: Huge potential in replacing aging, inefficient equipment and system retrofits.

-

Intelligent & Service-Led Transformation: Creating recurring revenue and enhancing stickiness through digital value-added services (e.g., energy performance contracting).

-

Import Substitution & Globalization: The combined advantages in technology, cost, and supply chain enable Chinese brands to replace foreign brands in mid-to-high-end markets and accelerate global expansion.