1. Industry Definition & Scope

The Packaging & Printing Industry is a vast and integral sector that combines the manufacturing of packaging materials, the conversion of these materials into functional packaging formats, and the application of graphics, text, and security features through various printing processes. It serves as a critical bridge between product manufacturers and consumers, fulfilling essential functions of protection, preservation, information, marketing, and logistics across virtually all sectors of the global economy.

2. Major Segments & Product Categories

-

By Packaging Material & Type:

-

Paper & Paperboard Packaging: Corrugated boxes, folding cartons, paper bags, labels, flexible paper packaging.

-

Plastic Packaging: Rigid containers (bottles, tubs, trays), flexible films & pouches, bags, blister packs, shrink sleeves.

-

Glass Packaging: Bottles and jars for beverages, food, pharmaceuticals, and cosmetics.

-

Metal Packaging: Cans (steel, aluminum) for food and beverages, aerosol cans, closures (caps, lids).

-

Composite & Other Packaging: Aseptic cartons, stand-up pouches, and packaging using biodegradable/novel materials.

-

-

By Primary Function:

-

Primary Packaging: In direct contact with the product (e.g., beverage bottle, cereal box).

-

Secondary Packaging: Groups primary packages together (e.g., a cardboard box holding 12 cans).

-

Tertiary/Transport Packaging: For bulk handling and shipping (e.g., pallets, stretch wrap, large corrugated boxes).

-

-

By Printing Process & Technology:

-

Traditional Commercial Printing: Offset lithography (for high-volume, high-quality paper/board), flexography (dominant for flexible packaging and corrugated), gravure (for very long runs, high quality on films and paper).

-

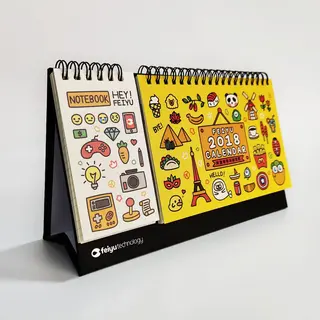

Digital Printing: Inkjet and electrophotography (toner-based). Enables short runs, customization, variable data, and rapid prototyping. Growing rapidly in labels, folding cartons, and corrugated.

-

Screen Printing: For specialty applications on uneven surfaces (e.g., bottles, electronics).

-

Other Processes: Letterpress, pad printing, and finishing techniques (embossing, foil stamping, varnishing, die-cutting).

-

3. Industry Chain Structure

Upstream:

-

Raw Material Suppliers: Pulp & paper mills, plastic resin producers, aluminum & steel mills, glass manufacturers, ink & coating chemical companies, adhesive producers.

-

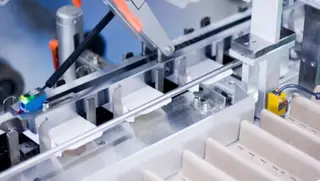

Machinery & Equipment Manufacturers: Producers of printing presses (offset, flexo, digital), die-cutters, platemakers, bag-making machines, extruders (for plastics), bottle-blowing machines.

Midstream (Converters & Printers):

-

Packaging Converters: Companies that purchase raw materials (e.g., rolls of paper, plastic film) and convert them into finished packaging (boxes, bags, pouches). They often integrate printing.

-

Integrated Giants: Companies like Amcor, WestRock, Mondi, and Sealed Air operate globally across multiple material types.

-

-

Specialty Printers: Focus on specific processes or niches (e.g., label printers, security printers, commercial sheet-fed printers).

-

Pre-Press & Design Services: Creation of digital artwork, structural design, and production of printing plates or digital files.

Downstream:

-

End-User Industries (The Customers):

-

Food & Beverage (largest segment)

-

Pharmaceutical & Healthcare

-

Personal Care & Cosmetics

-

Consumer Electronics

-

E-commerce & Logistics

-

Industrial Goods

-

-

Brand Owners & FMCG Companies: The primary specifiers and purchasers of packaging, driving demand for innovation and branding.

-

Consumers & Waste Management: The final interaction point and the start of the post-consumer lifecycle, placing sustainability pressure on the industry.

4. Key Market Dynamics & Characteristics

-

Ubiquitous & Non-Cyclical Demand: Essential for virtually all consumer and industrial goods, providing relative stability.

-

Growth Driven by Consumer Trends: E-commerce (demand for protective shipping materials), convenience/smaller households (demand for single-serve and flexible packaging), sustainability, and premiumization.

-

High Sensitivity to Raw Material Costs: Profit margins are heavily impacted by the price volatility of paper pulp, plastics, and energy.

-

Short-Run & Customization Trend: The rise of SKU proliferation, regional marketing, and DTC brands drives demand for digital printing's agility.

-

Consolidation & Scale: Large converters are acquiring smaller players to gain scale, geographic reach, and technological capabilities.

-

Intense Regulatory & Environmental Pressure: Governments worldwide are enacting laws to reduce plastic waste, increase recyclability, and enforce extended producer responsibility (EPR).

5. Development Trends

-

Sustainability & Circular Economy:

-

Design for Recycling: Mono-material structures, easier-to-separate components.

-

Use of Recycled Content: Post-consumer recycled (PCR) resins and papers.

-

Renewable & Biodegradable Materials: Growth in bio-based plastics and compostable packaging.

-

Lightweighting & Source Reduction: Using less material without compromising performance.

-

-

Digitalization & Smart Packaging:

-

Digital Printing Growth: For mass customization, versioning, and supply chain agility.

-

Smart & Active Packaging: Integrating QR codes, NFC tags, sensors for traceability, authenticity, freshness monitoring, and consumer engagement.

-

Automation & AI: AI-driven predictive maintenance on presses, automated quality inspection, and optimized production planning.

-

-

E-commerce-Driven Innovation:

-

Development of right-sized, protective, and easy-to-open shipping packaging.

-

Branded "unboxing experiences" even for shipping boxes.

-

Solutions to reduce "ship in own container" waste.

-

-

Enhanced Brand Engagement & Functionality:

-

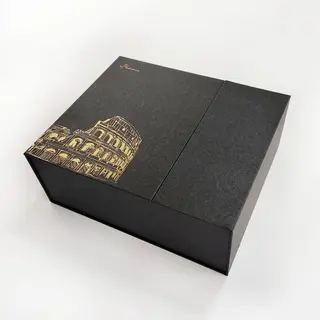

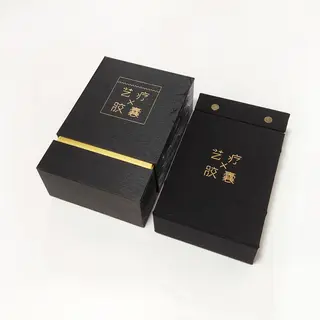

High-end finishes and tactile effects (textured coatings, embossing) to create shelf impact.

-

Functional coatings for improved barrier properties (oxygen, moisture), anti-microbial surfaces, or easy-to-clean features.

-

-

Supply Chain Resilience & Transparency:

-

Packaging as a tool for track-and-trace and combating counterfeiting.

-

Near-shoring of production to reduce logistics risk and lead times.

-

6. Major Challenges & Opportunities

Challenges:

-

Sustainability Compliance Costs: High investment required to redesign packaging, source sustainable materials, and build recycling infrastructure.

-

Plastic Scrutiny & Public Perception: Managing the reputation of plastic packaging and finding viable alternatives.

-

Talent & Skills Gap: Difficulty attracting and retaining skilled press operators and technicians in an increasingly digital/automated environment.

-

Overcapacity & Price Competition: In many traditional segments (e.g., standard corrugated), leading to margin pressure.

-

Complexity of Global Regulations: Navigating differing EPR, labeling, and material restrictions across countries.

Opportunities:

-

E-commerce as a Permanent Growth Engine: Continuous innovation in protective, sustainable, and brand-enhancing e-commerce packaging.

-

Premium & Luxury Market Growth: High-value opportunities in luxury goods, cosmetics, and premium food/beverage packaging.

-

Pharma & Healthcare Security: Demand for tamper-evident, child-resistant, and track-and-trace compliant packaging.

-

Service & Solution Model: Shifting from selling "boxes" to providing integrated packaging solutions (design, sourcing, fulfillment, sustainability reporting).

-

Digital Transformation Leaders: Companies that successfully adopt and scale digital printing and smart packaging technologies will capture high-growth, high-margin segments.