Industry Definition & Scope

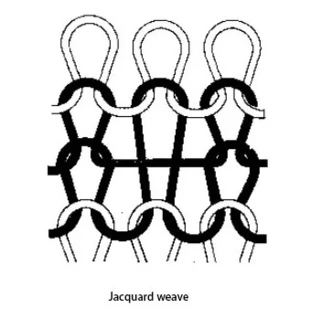

The knitting machine industry encompasses the design, manufacturing, and distribution of mechanical and electronic devices that automate the process of creating knitted fabrics or garments by interlocking loops of yarn. This specialized industrial sector serves both large-scale commercial production and small-scale craft or entrepreneurial applications, bridging advanced manufacturing technology with textile artistry.

Key Product Categories

By Technology & Automation Level:

-

Mechanical Knitting Machines: Operated manually via hand cranks or punch cards, including flatbed and circular machines for hobbyists and small producers.

-

Electronic Knitting Machines: Computer-controlled machines with motorized carriage movement, pattern memory, and automated functions for complex designs.

-

Computerized Knitting Systems: Industrial-grade systems with CAD/CAM integration, capable of full garment knitting and 3D shaping with minimal manual intervention.

-

Sock Knitting Machines: Specialized circular machines designed specifically for producing seamless hosiery and socks.

-

Sweater Knitting Machines: Flatbed machines optimized for knitting garment panels and assembling complete sweaters.

By Machine Type & Construction:

-

Flat Knitting Machines: Machines with needles arranged in a straight line on a flat bed, primarily used for producing shaped panels and complete garments.

-

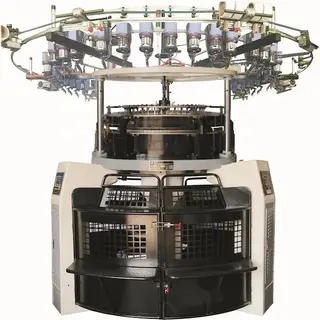

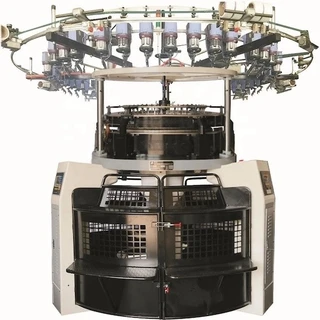

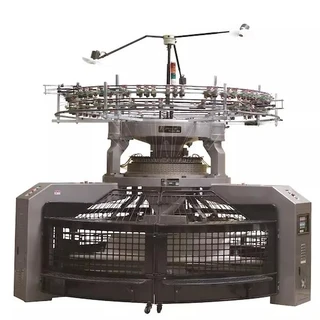

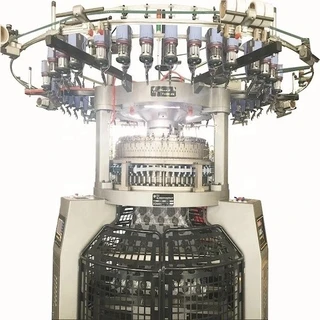

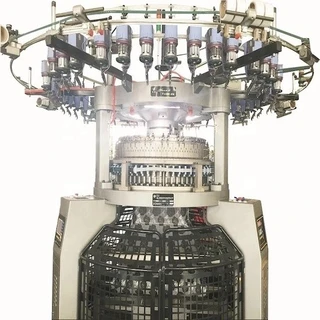

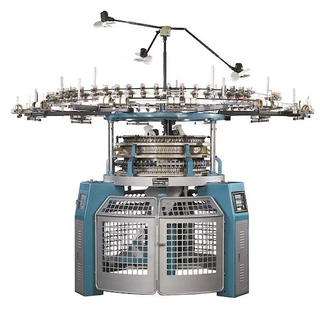

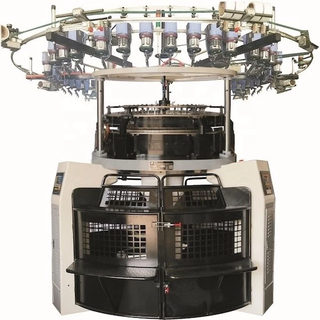

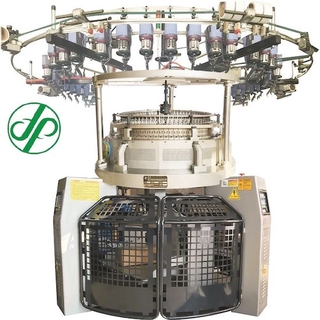

Circular Knitting Machines: Machines with needles arranged in a circle, used primarily for producing tubular fabrics for T-shirts, underwear, and seamless garments.

-

Warp Knitting Machines: Industrial machines that produce fabrics with vertical chain stitches, used for technical textiles, lingerie, and netting.

-

Domestic/Semi-Industrial Machines: Smaller machines designed for home use, small businesses, or educational purposes.

By Market Segment:

-

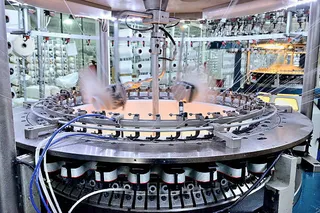

Industrial Textile Manufacturing: High-speed, multi-feed machines for mass production of knitted fabrics and garments.

-

Small-Batch Production: Versatile machines suitable for fashion designers, startup brands, and custom manufacturers.

-

Craft & Hobbyist Market: User-friendly machines for home crafters and knitting enthusiasts.

-

Technical Textile Production: Specialized machines for medical textiles, automotive interiors, and industrial fabrics.

Technology & Innovation Trends

-

Digital Integration & IoT Connectivity: Machines with cloud connectivity for remote monitoring, predictive maintenance, and software updates.

-

3D Knitting Technology: Advanced flat knitting machines capable of producing complete seamless garments with integrated shaping and reduced waste.

-

Smart Yarn Feeding Systems: Automated tension control and multiple yarn carrier systems for complex colorwork and pattern accuracy.

-

Energy-Efficient Designs: Reduced power consumption through optimized motor systems and standby modes.

-

User-Friendly Software Interfaces: Intuitive touchscreen controls and simplified programming for complex patterns.

-

Modular & Upgradeable Systems: Machines designed with interchangeable components to extend functionality and lifespan.

-

Sustainable Manufacturing Features: Reduced yarn waste through precise calculation and efficient needle bed utilization.

Global Market Drivers

-

Demand for Automated Textile Production: Need for efficiency and consistency in apparel manufacturing.

-

Growth of Customization & Small-Batch Fashion: Rise of on-demand production and personalized garments.

-

Technical Textile Expansion: Increasing applications in medical, sports, and industrial sectors.

-

Craft Technology Adoption: Hobbyists upgrading from hand knitting to machine-assisted production.

-

Reshoring & Localized Manufacturing: Revival of small-scale textile production in developed markets.

-

Fashion Industry Speed Requirements: Need for rapid prototyping and short production runs.

Industry Value Chain

-

Raw Material Suppliers: Providers of metals, electronics, motors, and specialized components.

-

Machine Manufacturers: Companies designing and assembling complete knitting systems.

-

Software Developers: Creators of pattern design and machine control software.

-

Distributors & Dealers: Sales channels serving industrial clients and retail customers.

-

Training & Support Providers: Technical education and maintenance services.

-

End Users: Textile mills, fashion companies, small businesses, and individual crafters.

Key Industry Challenges

-

High Capital Investment Requirements: Significant upfront costs for industrial-grade equipment.

-

Technical Skill Gap: Shortage of trained operators and technicians.

-

Competition from Low-Cost Manufacturing Regions: Pressure from used equipment markets and Asian manufacturers.

-

Rapid Technological Obsolescence: Fast pace of innovation requiring frequent upgrades.

-

Supply Chain Complexity: Dependence on specialized electronic and mechanical components.

-

Market Education Needs: Overcoming perception of knitting machines as difficult to operate.

Future Outlook

-

Democratization of Knitting Technology: More affordable and accessible machines for small producers and individuals.

-

Integration with AI & Machine Learning: Automated pattern generation and optimization algorithms.

-

Circular Production Systems: Machines designed for recycling and upcycling yarn materials.

-

Hybrid Manufacturing Approaches: Combining knitting with other technologies like 3D printing or embroidery.

-

Smart Factory Integration: Fully automated knitting cells within Industry 4.0 manufacturing environments.

-

Educational & Maker Space Adoption: Increased use in schools, universities, and community workshops.