Industry Definition & Scope

The industrial pipes industry involves the design, manufacturing, supply, and installation of tubular products used to convey fluids, gases, slurries, and solids across industrial applications. As critical infrastructure components, industrial pipes ensure safe, efficient, and reliable transport of materials in energy, chemical, water, and manufacturing sectors.

Key Product Categories

-

By Material Type:

-

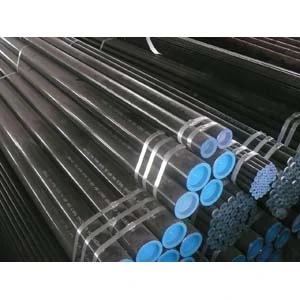

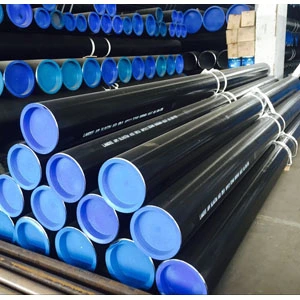

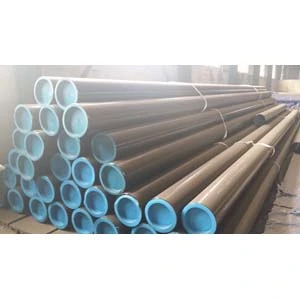

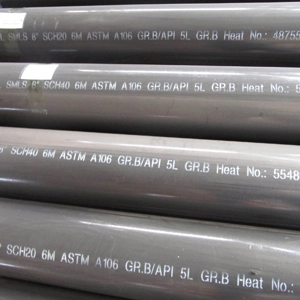

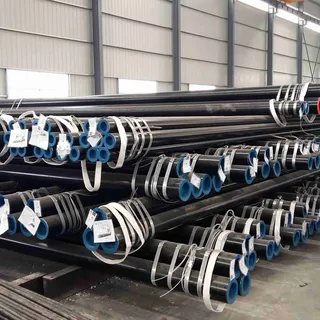

Carbon Steel Pipes: ASTM A106, API 5L for general industrial applications

-

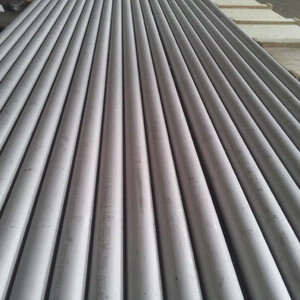

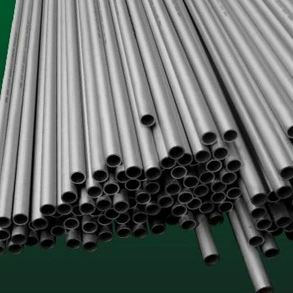

Stainless Steel Pipes: ASTM A312 (304/316) for corrosive environments

-

Alloy Steel Pipes: ASTM A335 (P11/P22/P91) for high-temperature service

-

Non-Metallic Pipes: HDPE, PVC, FRP, GRP for corrosion resistance

-

Duplex & Super Duplex: For offshore and chemical processing

-

Specialty Alloys: Inconel, Monel, Titanium for extreme conditions

-

-

By Manufacturing Process:

-

Seamless Pipes: Hot-finished or cold-drawn for high-pressure applications

-

Welded Pipes: ERW (Electric Resistance Welded), SAW (Submerged Arc Welded), LSAW (Longitudinal SAW)

-

Spiral Welded Pipes: Large diameter water and slurry transportation

-

Extruded Pipes: For plastics and composite materials

-

-

By Application:

-

Oil & Gas: Line pipe, OCTG (casing/tubing), flow lines, risers

-

Power Generation: Boiler tubes, steam lines, condenser tubes

-

Chemical Processing: Process piping, reactor coils, heat exchangers

-

Water Infrastructure: Transmission mains, distribution pipes, sewer systems

-

Mining & Minerals: Slurry pipelines, tailings disposal systems

-

Pharmaceutical & Food: Sanitary tubing, CIP systems

-

-

By Coating & Lining:

-

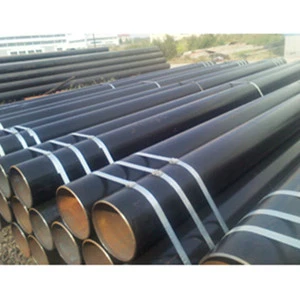

External Coatings: FBE, 3LPE, coal tar enamel for corrosion protection

-

Internal Linings: Cement mortar, epoxy, polyethylene for flow efficiency

-

Clad Pipes: Metallurgically bonded bimetallic pipes

-

Technology & Innovation Trends

-

Digital Pipeline Management: IoT sensors for real-time monitoring of pressure, flow, and corrosion

-

Advanced Materials: Nano-coated pipes for enhanced corrosion resistance, composite materials for weight reduction

-

Smart Manufacturing: Automated welding, AI-based defect detection, robotic inspection

-

Sustainability Solutions: Leak detection systems, energy-efficient transport designs

-

Modular Prefabrication: Pre-engineered pipe spools for faster installation

Global Market Drivers

-

Global energy transition investments (hydrogen pipelines, CO₂ transport, LNG infrastructure)

-

Replacement of aging pipeline networks in developed economies

-

Urbanization driving water and wastewater infrastructure projects

-

Growth in chemical manufacturing and processing industries

-

Stringent environmental and safety regulations (API, ASME, ISO standards)

-

Expansion of mining and mineral processing operations

Major Players & Value Chain

-

Steel Pipe Manufacturers: Vallourec, Tenaris, TMK, Nippon Steel, Jindal SAW

-

Specialty Pipe Producers: Georg Fischer (GF), Uponor, Aliaxis, Chevron Phillips

-

Chinese Manufacturers: Baosteel, Tianjin Pipe, Hengyang Steel Tube

-

Value Chain: Raw material suppliers → pipe manufacturers → coating/lining services → distributors/stockists → EPC contractors → end-users

Challenges & Opportunities

-

Challenges: Volatile raw material prices, overcapacity in certain segments, environmental compliance costs, technical skill shortages

-

Opportunities: Digital twin technology integration, hydrogen-ready pipeline systems, water scarcity solutions (desalination pipes), emerging market infrastructure development, circular economy initiatives (pipe recycling)