Industry Definition & Scope

The globe valves industry encompasses the design, manufacturing, and application of linear-motion valves characterized by a spherical body shape and a movable plug (disc) that seats against a stationary ring to regulate fluid flow. Renowned for precise throttling capabilities, excellent shutoff performance, and versatility in pressure and temperature ranges, globe valves are essential components in industries requiring accurate flow control and regulation.

Key Product Categories

-

By Design Configuration:

-

Standard Pattern Globe Valves: Conventional Z-body design with horizontal seating

-

Angle Pattern Globe Valves: 90-degree turn design for directional change applications

-

Y-Pattern Globe Valves: Inclined stem design for reduced pressure drop

-

Needle Valves: Precision throttling valves with tapered plug design

-

Three-Way Globe Valves: Multi-port configurations for mixing or diverting flow

-

Bellows Seal Globe Valves: Hermetic stem sealing for hazardous or toxic fluids

-

-

By Disc & Seat Design:

-

Plug Disc Design: Tapered or parabolic for precise throttling

-

Ball Disc Design: Quick-opening characteristics

-

Composition Disc Design: Renewable soft seats for tight shutoff

-

Metal-to-Metal Seating: For high-temperature applications

-

Balanced Plug Design: Pressure-balanced for high-pressure drops

-

-

By Material Construction:

-

Body Materials: Carbon steel (A216 WCB), stainless steel (A351 CF8/CF8M), alloy steel (WC6/WC9), bronze, Monel, Inconel

-

Trim Materials: 13% Cr, Stellite 6, Tungsten Carbide, Hastelloy, Ceramic

-

Seat Rings: Removable/renewable, integral welded, hard-faced

-

Stem Materials: 316SS, 416SS, Monel K500, Inconel 718

-

Gasket Materials: Spiral-wound (SS/Graphite), RTJ, Soft cut gaskets

-

-

By Application Specifications:

-

Power Generation: Main steam, feedwater, turbine bypass valves (MSS SP-80/81)

-

Oil & Gas: Choke valves, wellhead control, manifold systems (API 602/6A)

-

Chemical Processing: Corrosive service valves with alloy trim (NACE MR0175)

-

HVAC Systems: Balancing and control valves for heating/cooling circuits

-

Marine Applications: Sea water cooling, fuel oil, lube oil systems

-

Nuclear Power: Nuclear Class 1, 2, 3 valves (ASME Section III)

-

Cryogenic Service: Extended stem designs for LNG (-196°C)

-

Technology & Innovation Trends

-

Precision Flow Control Technology:

-

Characterized plug designs for equal percentage/linear flow characteristics

-

Anti-cavitation trim designs with multiple stages pressure reduction

-

Low-noise trim for high-pressure drop applications

-

-

Digital Integration & Smart Features:

-

Smart positioners with digital protocols (HART, Foundation Fieldbus, Profibus)

-

IoT-enabled diagnostics for predictive maintenance

-

Digital twins for flow simulation and performance optimization

-

Automated calibration systems with self-diagnostics

-

-

Advanced Material Engineering:

-

Nanostructured coatings for erosion resistance in particulate-laden flows

-

Composite materials for severe service conditions

-

Additive manufactured trim components for customized flow characteristics

-

High-temperature alloys for ultra-supercritical power plants

-

-

Sealing Technology Innovations:

-

Live-loaded packing systems for fugitive emission compliance

-

Bellows seal designs for zero-emission requirements

-

Fire-safe designs per API 607/ISO 10497

-

Cryogenic sealing materials for LNG and industrial gases

-

Global Market Drivers

-

Power plant modernization and ultra-supercritical technology adoption

-

Oil and gas production optimization and digital oilfield initiatives

-

Chemical industry expansion and process intensification

-

Renewable energy integration (geothermal, concentrated solar)

-

Water and wastewater treatment infrastructure upgrades

-

Stricter environmental regulations on emissions and efficiency

-

Industrial automation and Industry 4.0 implementation

Major Players & Value Chain

-

Global Leaders: Emerson (Fisher), Flowserve, Velan, IMI Precision Engineering, Samson

-

Specialty Manufacturers: Control Components Inc. (CCI), ValvTechnologies, MOGAS, Metso

-

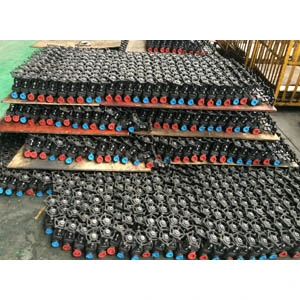

Regional Leaders: China (Zhejiang, Jiangsu manufacturers), India (Forbes Marshall, L&T)

-

European Specialists: KSB, Gestra, Spirax Sarco, SchuF Group

-

Value Chain: Material suppliers → component manufacturing → valve assembly → testing/calibration → actuation integration → system engineering → end-users

Challenges & Opportunities

-

Challenges:

-

High pressure drop compared to other valve types

-

Maintenance complexity in high-cycle applications

-

Competitive pressure from ball and butterfly valves in some applications

-

Technical skill shortage in precision valve engineering

-

Material cost volatility for special alloys

-

-

Opportunities:

-

Digital valve ecosystem integration for smart process control

-

Hydrogen economy infrastructure development

-

Carbon capture, utilization and storage (CCUS) applications

-

Nuclear power plant life extension and new construction

-

Aftermarket services: calibration, repair, digital retrofits

-

Emerging market power and industrial infrastructure development

-