Industry Definition & Scope

The gaskets industry encompasses the design, manufacturing, and supply of sealing components placed between mating surfaces in mechanical assemblies to prevent leakage of fluids or gases. As critical sealing solutions, gaskets ensure system integrity, safety, and efficiency across industrial, automotive, aerospace, and infrastructure applications by creating reliable static seals under compression.

Key Product Categories

-

By Material Type:

-

Non-Metallic Gaskets: Rubber (NBR, EPDM, Viton), PTFE, graphite, fiber, compressed non-asbestos (CNAF)

-

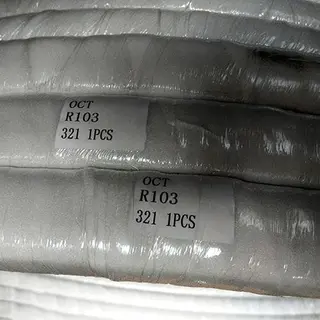

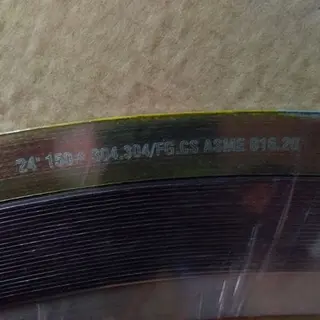

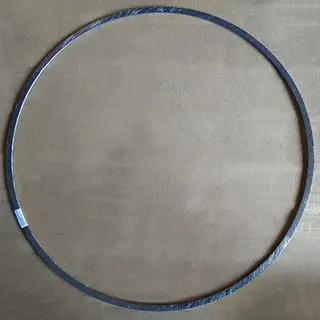

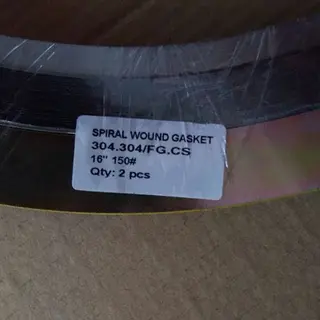

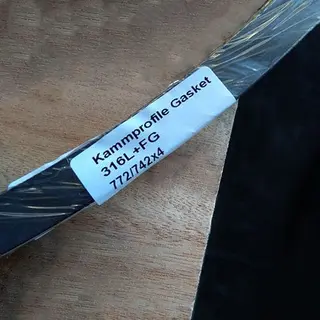

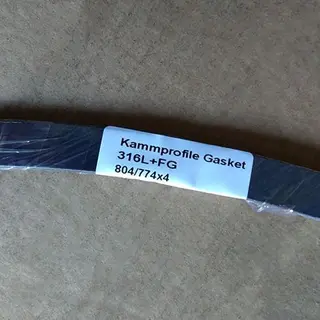

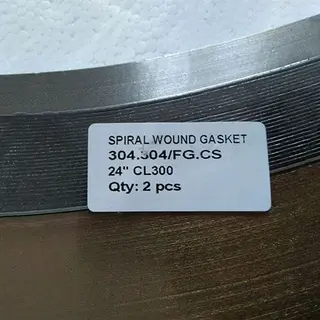

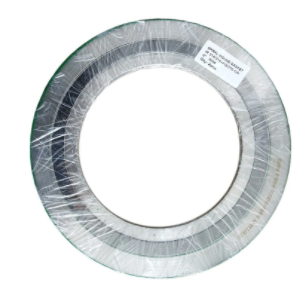

Semi-Metallic Gaskets: Spiral-wound (SS/graphite, SS/PTFE), metal-jacketed, camprofile (grooved metal)

-

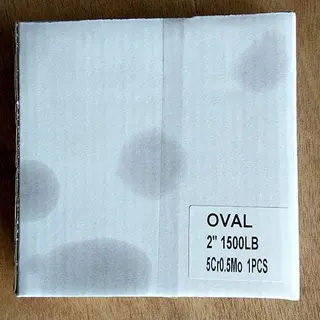

Metallic Gaskets: Ring-type joints (RTJ), oval/octagonal rings, flat metal, lens rings

-

Composite Gaskets: Rubber-metal bonded, expanded PTFE (ePTFE), graphite foil with metal inserts

-

-

By Application Design:

-

Flange Gaskets: For pipe, valve, and vessel flange connections

-

Heat Exchanger Gaskets: Plate, shell & tube, and spiral heat exchanger seals

-

Engine/Vehicle Gaskets: Cylinder head, exhaust, fuel system, and transmission seals

-

Pump & Compressor Gaskets: Mechanical seals, housing covers, and connection seals

-

Sanitary/Hygienic Gaskets: Tri-clamp, DIN, SMS standards for food/pharma

-

Electrical Enclosure Gaskets: EMI/RFI shielding and environmental sealing

-

-

By Industry Standards:

-

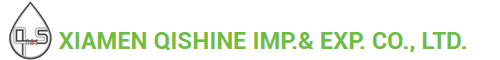

ASME Standards: B16.20 (Ring gaskets), B16.21 (Flat gaskets)

-

API Standards: API 6A (Wellhead), API 601 (Metallic gaskets)

-

DIN/EN Standards: EN 1514, DIN 2690 series

-

ISO Standards: ISO 7483, ISO 27509 (Petroleum industry)

-

Automotive Standards: ASTM, SAE, OEM specifications

-

Technology & Innovation Trends

-

Advanced Material Development:

-

Nanocomposite gasket materials with enhanced sealing properties

-

Graphene-enhanced graphite for higher temperature/pressure resistance

-

Bio-based elastomers for sustainable sealing solutions

-

High-performance ePTFE with improved creep resistance

-

-

Digital Manufacturing Integration:

-

Laser cutting and waterjet cutting for precision shape production

-

3D scanning for custom gasket reverse engineering

-

AI-based material selection algorithms for optimal performance

-

Digital inventory and on-demand manufacturing platforms

-

-

Smart Gasket Technology:

-

Embedded sensors for real-time pressure and temperature monitoring

-

RFID tags for traceability and maintenance history

-

Leak detection integrated gaskets with wireless alerts

-

Phase-change materials for self-adjusting compression

-

-

Environmental & Safety Focus:

-

Fugitive emission control gaskets meeting ISO 15848 standards

-

Low VOC and formaldehyde-free materials

-

Fire-safe gaskets (API 607/BS 6755 Part 2)

-

Recyclable and reusable gasket designs

-

Global Market Drivers

-

Stringent environmental regulations on emission control (EPA, TA-Luft)

-

Oil & gas industry expansion and pipeline integrity requirements

-

Automotive industry electrification and lightweight design trends

-

Pharmaceutical and food industry hygiene standards tightening

-

Power generation plant maintenance and upgrades

-

Aerospace industry demand for high-reliability sealing

-

Water and wastewater infrastructure development

-

Industrial automation driving precision sealing needs

Major Players & Value Chain

-

Global Leaders: Flexitallic, Garlock, Lamons, Teadit, James Walker, Frenzelit

-

Specialized Manufacturers: W. L. Gore (ePTFE), Parker Hannifin, SKF, John Crane

-

Regional Leaders: China (Zhejiang, Shandong manufacturers), India (Udhana, Mumbai clusters)

-

Automotive Specialists: Dana, Federal-Mogul, ElringKlinger, Trelleborg

-

Value Chain: Raw material suppliers → compound/formulation → cutting/molding → testing/certification → distributors → OEMs/MRO → end-users

Challenges & Opportunities

-

Challenges:

-

Raw material price volatility (graphite, PTFE, specialty elastomers)

-

Counterfeit and substandard products in price-sensitive markets

-

Technical complexity in extreme condition applications (hydrogen, cryogenics)

-

Competition from alternative sealing technologies (welding, sealing tapes)

-

Skills gap in proper gasket selection and installation

-

-

Opportunities:

-

Hydrogen economy infrastructure development

-

Electric vehicle battery and motor sealing solutions

-

Digital twin integration for predictive maintenance

-

Circular economy models for gasket recycling/reuse

-

Emerging market industrial growth

-

Aftermarket services and technical consulting

-