Industry Definition & Scope

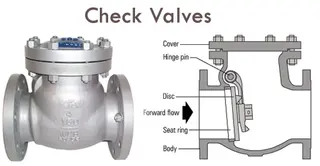

The check valves industry encompasses the design, manufacturing, and application of one-directional valves that automatically prevent fluid backflow in piping systems. As critical safety and system protection components, check valves ensure operational integrity and prevent equipment damage in diverse industrial, commercial, and residential applications.

Key Product Categories

-

By Design Configuration:

-

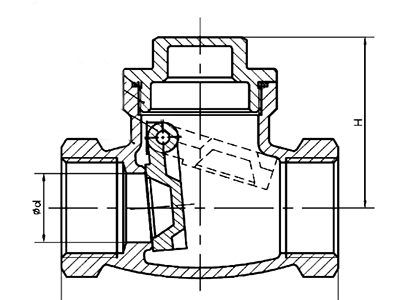

Swing Check Valves: Hinged disc design for horizontal and vertical flow (top-hinge, tilt-disc)

-

Lift Check Valves: Piston/poppet design for high-pressure applications

-

Ball Check Valves: Spherical closure element for viscous fluids

-

Dual-Plate/Wafer Check Valves: Compact spring-assisted twin-disc design

-

Nozzle Check Valves: Streamlined design for pump protection (API 6D compliant)

-

Foot Valves: Strainer-equipped inlet valves for pump suction lines

-

Silent/Spring Check Valves: Spring-loaded for rapid closure and water hammer prevention

-

-

By Material Construction:

-

Body Materials: Cast iron, ductile iron, carbon steel, stainless steel (304/316), bronze, brass, PVC, CPVC

-

Closure Elements: Stainless steel disc/ball, Nylon-coated, rubber-coated, composite materials

-

Seat Materials: Metal-to-metal, resilient seats (Buna-N, EPDM, Viton), PTFE inserts

-

Spring Materials: Inconel, Hastelloy, 316SS for corrosive environments

-

-

By Application Specifications:

-

Water & Wastewater: Resilient-seated valves (AWWA C508/C509 standards)

-

Oil & Gas: API 6D/6A check valves for pipeline and wellhead applications

-

Chemical Processing: Lined check valves (PTFE, PFA, rubber-lined)

-

Power Generation: High-temperature/pressure check valves for steam systems

-

HVAC Systems: Spring check valves for chilled/heating water circuits

-

Marine Applications: Bronze and naval brass valves for seawater systems

-

Pharmaceutical: Sanitary check valves with CIP/SIP capabilities

-

-

By Performance Characteristics:

-

Cracking Pressure: Range from 0.5 psi to 50+ psi depending on application

-

Closing Speed: Fast-closing for water hammer prevention, slow-close for surge control

-

Installation Orientation: Horizontal, vertical upflow, vertical downflow designs

-

Pressure Classes: ANSI 125-2500, PN10-PN400

-

Technology & Innovation Trends

-

Advanced Flow Dynamics:

-

Computational Fluid Dynamics (CFD) optimized disc designs for minimal pressure drop

-

Anti-water hammer designs with dashpot or damping mechanisms

-

Low-cracking pressure valves for precise system control

-

-

Material Engineering:

-

Composite discs with carbon fiber reinforcement for high-cycle applications

-

Nanocoatings for erosion/corrosion resistance in abrasive services

-

Cryogenic materials for LNG and industrial gas applications (-196°C and below)

-

-

Smart Monitoring Integration:

-

Acoustic sensors for disc movement monitoring and predictive maintenance

-

Position indicators with wireless transmission capabilities

-

IoT-enabled check valves for real-time backflow detection

-

-

Manufacturing Excellence:

-

Precision casting with robotic finishing for consistent sealing surfaces

-

Laser welding for critical nuclear and aerospace applications

-

Additive manufacturing for complex internal flow passages

-

Global Market Drivers

-

Water infrastructure modernization and non-revenue water reduction initiatives

-

Oil & gas pipeline expansion and integrity management requirements

-

Power plant maintenance and upgrade programs (conventional and renewable)

-

Industrial process automation and safety system enhancements

-

Stringent backflow prevention regulations in municipal water systems

-

Growth in chemical processing and pharmaceutical manufacturing

-

Marine industry development and offshore energy projects

Major Players & Value Chain

-

Global Leaders: Emerson, Flowserve, Velan, Crane, KITZ, IMI Critical Engineering

-

Specialized Manufacturers: Check-All Valve, DFT Inc., Val-Matic, CLA-VAL

-

Regional Leaders: China (Zhejiang, Jiangsu manufacturers), India (L&T, Audco), European specialists

-

Value Chain: Raw material suppliers → component manufacturing → valve assembly → testing/calibration → distribution network → system integrators → end-users

Challenges & Opportunities

-

Challenges:

-

Disc flutter and premature wear in pulsating flow applications

-

Water hammer damage in improperly specified installations

-

Material compatibility in extreme chemical and temperature conditions

-

Price competition from commoditized standard products

-

Counterfeit products in developing markets

-

-

Opportunities:

-

Smart water network integration for backflow monitoring

-

Renewable energy applications (geothermal, concentrated solar power)

-

Hydrogen economy infrastructure development

-

Nuclear power plant life extension programs

-

Aftermarket services: testing, maintenance, and retrofit solutions

-

Emerging market infrastructure development in Asia and Africa

-