Complete Guide to Double Eccentric Wafer Butterfly Valves in Industrial Systems

Introduction

In today's fast-evolving industrial landscape, process control technologies continue to play a pivotal role in ensuring efficiency, safety, and sustainability. Among key components influencing fluid control systems, the double eccentric wafer butterfly valve has emerged as a preferred choice for critical applications across oil & gas, petrochemical, power generation, water treatment, HVAC, and chemical processing sectors. This news report explores the design principles, performance benefits, industry trends, market dynamics, and future outlook for double eccentric wafer butterfly valves — underscoring their growing significance in modern infrastructure.

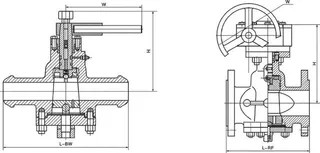

What Is a Double Eccentric Wafer Butterfly Valve?

A double eccentric wafer butterfly valve is a specialized quarter-turn valve designed to regulate flow by rotating a disc inside the valve body. Unlike traditional concentric butterfly valves where the disc shaft aligns centrally, the double eccentric design offsets the shaft twice — first, away from the centerline of the bore and second, off the sealing surface. This engineering innovation dramatically reduces friction and ensures tight shut-off performance.

The “wafer” designation refers to the valve's body style, which is sandwiched between two pipe flanges using bolts that pass through aligned holes in the flanges and valve body. This wafer style makes the valve compact, lightweight, and ideal for installations with restricted space.

Engineering Benefits & Operational Advantages

Double eccentric wafer butterfly valves offer several key benefits that set them apart from other flow control solutions:

Reduced Friction & Enhanced Seal Life

The double offset geometry ensures the disc moves away from the seat upon opening, minimizing contact during operation. This significantly reduces seat wear and prolongs service life — a major advantage in high-cycle applications.

Tight Shut-Off (Bubble-Tight Sealing)

Advanced seat materials (such as PTFE, U-PVC, RPTFE, or metal seats) and the eccentric design deliver superior sealing performance, often achieving Class VI shut-off per industry standards. This makes them suitable for applications requiring minimal leakage.

Lower Operating Torque

Because the disc doesn't rub against the seat during much of its travel, double eccentric valves require lower torque to operate — enabling easier actuation, reduced actuation cost, and greater suitability for automated control.

Compact & Lightweight

Compared with gate or globe valves, double eccentric wafer butterfly valves occupy less space and weigh significantly less — reducing structural loading and installation challenges in pipeline systems.

Versatile Flow Control

While some valves are optimized primarily for on/off service, double eccentric designs can handle throttling and modulation with greater stability and repeatability — expanding their utility in process control.

Core Industry Applications

Oil & Gas

In upstream, midstream, and downstream operations, reliable isolation and flow control are mission-critical. Double eccentric wafer butterfly valves are widely used for pipeline isolation, tank farm operations, and gas processing — offering quick response and tight sealing even under high pressure and temperature conditions.

Petrochemical & Chemical Processing

Chemical plants demand valves that withstand corrosive media, extreme temperatures, and frequent cycling. With appropriate body and seat materials, double eccentric butterfly valves provide dependable performance, especially in solvent handling, sulfuric acid processing, and polymer production lines.

Power Generation

In power plants (including fossil fuel, nuclear, and renewable facilities), these valves regulate cooling water, steam extraction, and feedwater systems. Their ability to perform under high temperature and fluctuating pressures makes them a valuable asset in turbine and boiler auxiliary systems.

Water & Wastewater Treatment

Municipal waterworks and wastewater treatment plants rely on butterfly valves to manage flow in treatment basins, filters, and distribution networks. The wafer style's simplicity and cost-effectiveness make it a frequent choice for large-diameter services in these sectors.

HVAC & Building Services

In heating, ventilation, and air conditioning systems, double eccentric wafer butterfly valves control chilled water, hot water, and air handling units — contributing to energy efficiency and precise climate control.

Materials & Construction Variants

The performance and suitability of a double eccentric wafer butterfly valve depend heavily on material selection. Common combinations include:

Valve Body Materials

Carbon Steel – Cost-effective and suitable for general industrial use.

- Stainless Steel (304/316) – Good corrosion resistance for chemical and food industries.

- Ductile Iron – Excellent strength and durability for waterworks and HVAC.

- Alloy Steels – High strength and temperature resistance for demanding applications.

Disc & Seat Materials

Disc and seat materials are selected based on media compatibility:

- PTFE & RPTFE – High corrosion resistance, excellent sealing.

- Nylon & Reinforced Polymers – Wear resistance and reduced friction.

- Metals (Stellite, Hard-faced Alloys) – Suitable for high temperature and abrasive media.

- Elastomers (EPDM, NBR) – Good flexibility and sealing for water and gas services.

Standards, Ratings & Compliance

To ensure safety, reliability, and interoperability, double eccentric wafer butterfly valves are manufactured and tested to meet multiple international standards:

- API 609 – Butterfly valves for the petroleum and natural gas industries.

- BS EN 593 – European standard for triple-offset and double-offset butterfly valves.

- ANSI/ASME B16.34 – Valve design, materials, and pressure-temperature ratings.

- ISO 5752 – Valve face-to-face dimensions.

- API 598 – Valve inspection and testing protocols.

These standards ensure valves can withstand specified pressure classes (e.g., PN10, PN16, PN25, PN40, PN100) and temperature ranges while delivering predictable performance.

Actuation & Control Technologies

While manual lever and gear operated configurations remain common, industry trends increasingly favor automated actuation for advanced control and integration:

Electric Actuators

Electric actuators provide precise positioning and are essential in systems requiring remote operation, sequencing, or integration with distributed control systems (DCS).

Pneumatic Actuators

Pneumatic actuators offer fast response and reliable performance in hazardous environments where electric actuation may not be suitable.

Smart Actuation & IoT Integration

Modern butterfly valves equipped with smart positioners and IoT sensors enable real-time performance monitoring — feeding data into predictive maintenance platforms to minimize unplanned downtime.

Market Trends & Demand Drivers

Industrial Expansion in Asia Pacific

Rapid industrialization, particularly across China, India, and Southeast Asia, has propelled demand for high-performance valves, including double eccentric wafer butterfly designs, in sectors such as oil & gas, petrochemical, and water infrastructure.

Focus on Energy Efficiency

As industries adopt energy-efficient processes and smart automation, valves that offer lower operating torque, minimal leakage, and integration with control systems are increasingly preferred.

Rise of Renewable Power

Renewable energy installations (solar, biomass, geothermal) use fluid control solutions for heat transfer, cooling, and steam generation. The adaptability of double eccentric butterfly valves makes them suitable for many renewable power contexts.

Aging Infrastructure Upgrades

In mature markets, the replacement of aging valves in utilities and industrial plants is driving retrofit demand. Double eccentric wafer butterfly valves are often selected for upgrade projects due to improved sealing, lower maintenance, and cost advantages over older valve types.

Innovation & Technological Advances

Manufacturers continue to innovate in ways that enhance performance, reliability, and user convenience:

Advanced Coatings & Surface Engineering

Coating technologies such as epoxy, PTFE fluoropolymer, and hard chrome plating extend valve life in corrosive, abrasive, or high-temperature environments.

Optimized Seal Geometry

Enhanced seat contours and precision machining techniques improve sealing performance while reducing wear — enabling bubble-tight shut-off even after millions of cycles.

Lightweight Composite Materials

Emerging use of composite materials in seat and body components reduces weight without compromising strength, ideal for large-diameter installations.

Digital Twins and Predictive Analytics

As digital transformation accelerates, manufacturers are incorporating digital twin models to simulate valve behavior under various scenarios — enabling better design optimization and maintenance forecasting.

Case Studies: Real-World Implementations

To illustrate their practical value, consider these representative deployments:

Refinery Fluid Control

In a major refinery expansion project, double eccentric wafer butterfly valves were installed in feedstock transfer lines. Their robust sealing and low friction operation led to fewer maintenance shutdowns and improved uptime during high-temperature cycles.

Water Treatment Plant Retrofit

A municipal water treatment facility replaced aging gate valves with double eccentric wafer butterfly valves. The retrofit reduced operating torque requirements, simplified control logic integration, and improved flow regulation for distribution networks.

Power Plant Cooling System

In a thermoelectric power plant, these valves were deployed in cooling water circuits. Their compact design and reliable throttling helped optimize heat transfer efficiency while reducing lifecycle costs compared with conventional ball valves.

Selection & Specification Best Practices

Choosing the right double eccentric wafer butterfly valve requires careful evaluation of key parameters:

- Media Properties – Viscosity, corrosivity, temperature, and particulate presence.

- Pressure & Temperature Ratings – Matching valve class to system requirements (PN10 to PN100 or higher).

- Material Compatibility – Ensuring body, disc, and seat materials resist corrosion and wear.

- Actuation Requirements – Manual vs automated (electric/pneumatic) based on control needs.

- Standards Conformance – Ensuring compliance with applicable regional and industry standards.

Experienced valve engineers and suppliers collaborate early in project design to align specifications with performance expectations and regulatory requirements.

Challenges & Solutions

While double eccentric wafer butterfly valves offer numerous advantages, certain challenges must be addressed:

Cavitation & Noise

In high-velocity applications, cavitation can erode seats and produce noise. Solution: Use anti-cavitation trims, staged throttling, and flow conditioning.

Abrasion from Particulates

Slurries or unfiltered media can abrade sealing surfaces. Solution: Hardened trim materials and frequent inspection cycles improve durability.

Installation Alignment

Improper flange alignment can impair sealing. Solution: Precise installation practices and alignment guides ensure optimum performance.

Sustainability & Environmental Impact

As global industries emphasize environmental stewardship, double eccentric wafer butterfly valves contribute to sustainability through:

- Leak-tight Sealing – Minimizes fugitive emissions.

- Reduced Material Footprint – Lighter weight and smaller size reduce resource usage.

- Extended Service Life – Lower replacement frequency minimizes waste.

- Automation Integration – Enables energy-efficient process control.

These attributes align with corporate ESG (Environmental, Social, Governance) goals, particularly in sectors committed to emissions reduction and resource optimization.

Supplier Landscape & Competitive Dynamics

The valve market features a mix of global valve manufacturers, regional specialists, and contract fabricators. Key competitive factors include:

- Product Quality & Standards Compliance

- Custom Engineering & Material Options

- After-Sales Support & Spare Parts Availability

- Delivery Lead Times

- Price & Total Cost of Ownership

In China, a growing number of manufacturers are investing in quality systems (ISO 9001, API Q1) and advanced production technologies to meet international demand while maintaining cost competitiveness.

Regulatory & Safety Considerations

Industrial applications often require valves to meet safety and performance certifications:

- CE Marking & PED Compliance (Europe)

- API Certification (Oil & Gas)

- TA-Luft & ISO 15848 (Emissions Control)

- Fire-Safe Certification (API 607 / ISO 10497)

Manufacturers perform rigorous testing, including pressure testing, seat leakage tests, and cycle life validation, to ensure compliance and safe operation.

Future Outlook: What's Next?

Looking ahead, the double eccentric wafer butterfly valve market is poised for continued growth driven by:

Digitalization & Smart Infrastructure

Expect more valves with embedded sensors and diagnostics, feeding data into plantwide asset management systems.

Custom Materials & Coatings

Emerging material science innovations will enable valves to handle ever-tougher media and extreme conditions.

Sustainable Manufacturing Practices

Manufacturers will emphasize eco-friendly production, waste reduction, and recycling programs.

Global Infrastructure Investment

Large-scale projects in energy, water, and manufacturing sectors will sustain long-term demand for high-performance flow control solutions.

Conclusion

From refining crude oil to distributing potable water, from cooling power turbines to processing chemicals, the double eccentric wafer butterfly valve has proven itself a versatile, cost-effective, and reliable choice for modern fluid control systems. Its engineered design reduces wear, enhances sealing performance, and enables efficient flow management across diverse industries. With continued innovation, global market expansion, and increasing integration with smart technologies, double eccentric wafer butterfly valves are set to remain a cornerstone of industrial valve solutions for years to come.

Send your message to this supplier

Related Articles from the Supplier

Complete Guide to Lubricated Plug Valves

- Jul 31, 2024

Complete Guide to Cryogenic Ball Valve Maintenance

- Aug 14, 2024

A Complete Guide to High Pressure Control Valve

- Jul 16, 2024

A Complete Guide to Ball Valve Maintenance

- Aug 30, 2024

The Complete Guide to Ductile Iron Gate Valves

- Sep 16, 2025

Related Articles from China Manufacturers

Complete Guide to Infrared Sensors

- Aug 21, 2024

Complete Guide to Low Fugitive Emission Valves

- Oct 16, 2025

Complete Guide to Floating Head Heat Exchanger

- Mar 24, 2025

Complete Guide to Heat Exchanger Installation

- Oct 28, 2025

Complete Guide to Diesel Generator Wiring

- Sep 12, 2025

Complete Guide to Diesel Generator Testing

- Oct 15, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.weldonvalves.com/news/complete-guide-to-double-eccentric-wafer-butterfly-valves-in-industrial-systems.html