Exploring Explosion-Proof Potential of Built-in Mechanical Positioners

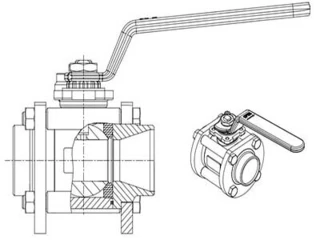

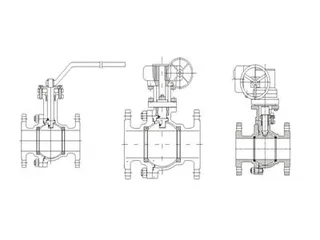

Magpie Valve Selection: Accurate Matching Ensures Reliable Control

Valve Technology Sharing

Exploring Explosion-Proof Potential of Built-in Mechanical Positioners

Can a mechanical positioner be explosion-proof when built into a system? To answer this, we must consider the structural characteristics of mechanical positioners, the principles of explosion protection, and the safety requirements of application environments. The following provides a comprehensive analysis.

Core of Explosion Protection in Mechanical Positioners: "No Electrical Spark" ≠ "Absolute Safety"

Mechanical positioners, purely mechanical devices without electrical components, coils, or wiring, offer a clear advantage in explosion-proof scenarios by eliminating sources of electrical ignition such as sparks or thermal effects. However, explosion protection is not solely defined by the absence of electricity. The following aspects must also be considered.

1. Potential Hazards from Mechanical Motion

Mechanical Sparks: Do internal metal parts (e.g., gears, linkages) generate friction or impact that could cause mechanical sparks when interacting with metal housings?

Static Discharge: If the medium is flammable or explosive, could friction between non-metallic parts (e.g., plastic or rubber) cause electrostatic buildup and discharge?

2. Applicability of Explosion-Proof Standards

Industrial explosion-proof regulations (e.g., ATEX, IECEx, GB 3836) address both electrical and non-electrical equipment, including risks from mechanical sparks and static electricity.

Purely mechanical structures can meet explosion-proof requirements if:

Proper materials are used (e.g., anti-static metals/non-metals with treated surfaces),

Structural design minimizes friction and ensures grounding.

Crucially, such claims must be backed by official explosion-proof certification specific to non-electrical devices.

Key Requirements for Explosion-Proof Built-in Mechanical Positioners

To ensure that a built-in mechanical positioner complies with explosion-proof standards, the following conditions must be met.

1. Explosion-Proof Design of the Positioner Itself

Materials: Avoid spark-prone metals like aluminum-magnesium alloys. Prefer stainless steel or other low-friction materials. Non-metal parts must be anti-static (surface resistance ≤10⁹Ω).

Structure:

Control clearances between moving parts to avoid excessive friction and heat generation.

Ensure components like springs or linkages are reliably grounded to the valve body/piping to prevent static buildup.

Certification: Is there a specific explosion-proof certification confirming the mechanical structure poses no risk of mechanical ignition?

2. Matching the Installation Environment's Explosion Risk Level

Verify the hazardous area classification of the plant:

Zone 0 (continuous presence of explosive gas): Rarely allows any non-electrical internal components; demands the highest safety level.

Zone 1/Zone 2: May permit mechanical positioners if designed and certified as described above, but must align with technical documentation from the manufacturer.

3. Comparison with Intelligent Positioners in Explosion-Proof Contexts

|

Type |

Explosion-Proof Method |

Advantages |

Risks |

|

Intelligent |

Electrical protection (intrinsic safety or flameproof) |

Mature certification, suitable for high-risk areas |

High cost, requires electrical safety design |

|

Mechanical |

Structural protection (materials/clearance control) |

No electrical risks, low cost |

Depends on design reliability, less certification availability |

Practical Recommendations: Balancing Cost and Safety

1. Prioritize Explosion-Proof Certification

Request the manufacturer to provide non-electrical explosion-proof test reports, such as compliance with GB 3836.1/3836.12 standards.

Ensure compatibility with the target gas group (e.g., IIA, IIB, IIC) and temperature class (e.g., T3, T4).

If no official certification is available, even structurally "safe-looking" designs may carry compliance risks, especially in highly regulated industries like chemicals or pharmaceuticals.

2. Optimize the Internal Design of the Mechanical Positioner

If internal installation is necessary, consider asking the manufacturer to provide an explosion-proof enclosure:

Material: Cast iron or stainless steel;

Ensure the enclosure meets strength and sealing requirements and does not interfere with the positioner's stroke or feedback accuracy.

Proper grounding of the enclosure and connected pipelines is essential to prevent static accumulation.

3. Consider Alternative Solutions

For highly hazardous areas (e.g., Zone 1), consider low-cost intelligent positioners (e.g., single-channel, non-bus types) to ensure compliance, avoiding safety incidents or costly retrofits.

In less hazardous zones (e.g., Zone 2 or well-ventilated areas), mechanical positioners may suffice, but always verify accurate zoning of the working environment.

Conclusion

In theory, mechanical positioners can achieve explosion-proof compliance through careful design. However, the key lies in certified materials and processes, and alignment with the specific explosion-risk level of the working environment.

To balance cost and safety, users are advised to:

First confirm the hazardous zone classification and gas characteristics of the site.

Request documented explosion-proof technical verification from the positioner manufacturer, do not rely solely on the assumption that "non-electrical" means "safe."

In high-risk scenarios, prefer certified intelligent positioners to avoid greater losses from safety oversights.

Ultimately, explosion-proof compliance is non-negotiable and must be based on authoritative certification and technical validation, not assumptions about mechanical structures lacking electrical components.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/media-hub/exploring-explosion-proof-potential-of-built-in-mechanical-positioners.html