Classification of Non-Metallic Gaskets Based on Material & Properties

Magpie Sealing Technology Insights

Flanges and Gaskets – Forms of Non-Metallic Gaskets (Part 3): Classification of Non-Metallic Gaskets Based on Material and Properties

In today's industrial applications, various types of non-metallic gaskets (sheets) are widely used due to their excellent adaptability and cost-effectiveness. Based on material composition and performance characteristics, non-metallic gaskets can be broadly classified into the following main categories:

Common Types of Non-Metallic Gaskets

To better understand the role of non-metallic gaskets in industrial sealing, let's explore the most commonly used types and their distinctive characteristics.

1. Rubber Gaskets (Elastomer Sheets)

Made primarily from elastomeric materials known for their flexibility and sealing ability, rubber gaskets are extensively used across many industrial sectors due to their unique physical and chemical properties.

2. Asbestos Rubber Gaskets

Now banned due to health and environmental concerns.

3. Non-Asbestos Rubber Gaskets

Developed as an eco-friendly alternative to asbestos-based products, these gaskets offer reliable sealing performance while ensuring safety and environmental compliance.

4. PTFE Gaskets

Composed of pure PTFE, filled PTFE, or expanded PTFE, these gaskets exhibit excellent chemical resistance and stability. They are widely utilized in the chemical, pharmaceutical, and food industries.

5. Graphite Gaskets

Made from graphite, these gaskets possess outstanding thermal conductivity and chemical resistance. They are especially well-suited for applications involving high temperatures and corrosive environments.

These are the primary types of non-metallic gaskets commonly used in industrial settings. Each offers distinct advantages, giving engineers and operators a wide range of solutions to meet various operational requirements.

Composite Non-Metallic Gaskets

A special category within non-metallic gaskets is the composite or jacketed non-metallic gasket, designed to resist aggressive media while maintaining excellent compressibility and recovery. This type of gasket aims to deliver high sealing performance with cost-effectiveness.

Typically, a layer of PTFE is laminated onto a base made of non-asbestos rubber composite board or standard rubber sheet. This composite structure leverages the strengths of both materials, chemical resistance from PTFE and elasticity from rubber, for enhanced sealing efficiency.

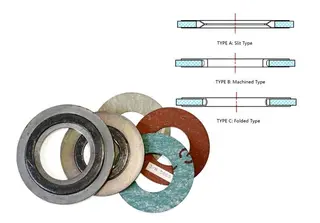

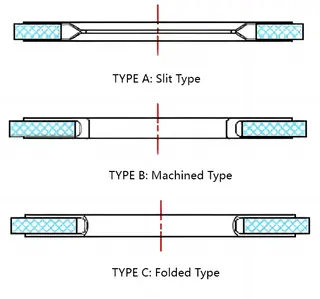

The main types of jacketed structures include:

- Slit Type

- Machined Type

- Folded Type

These structural variations cater to different industrial needs, making this gasket type highly adaptable and suitable for a wide range of applications.

For sealing issues, Magpie Sealing has the solution.

If you have questions or need technical guidance in the field of sealing technology, feel free to follow Magpie Sealing, leave comments, or contact us directly. Thank you for your attention, and stay tuned for the next part of our series on gasket forms. See you next time!

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Classification of Steel Castings

- Aug 30, 2014

Classification of Cam Lock Based on Structure

- Jul 21, 2016

Classification of Pressure Vessels in China

- Jul 15, 2017

Classification of Several Common Cam Locks

- Sep 05, 2020

Classification of Shot Blasting Machine

- Aug 08, 2016

Classification of Safety Valves

- Jul 18, 2016

Classification of Steel Castings

- Aug 30, 2014

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/classification-of-non-metallic-gaskets-based-on-material-and-properties.html