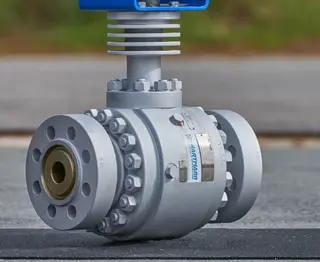

High Pressure Trunnion Ball Valve, A105N, 2-48 IN, CL150-2500

Product Name: High Pressure Trunnion Ball Valve

Type: Trunnion Mounted Ball Valve

Body Material: ASTM A105N, Carbon Steel

Size Range: NPS 2-48 Inch, DN50-DN1200

Design Pressure: Class 150-2500 LB, PN10-PN420

Ends Connections: RTJ Flanged

Operation: Gear Operated

Medium: Water, Gas, Oil, etc

Temperature Range: -46°C to 120°C

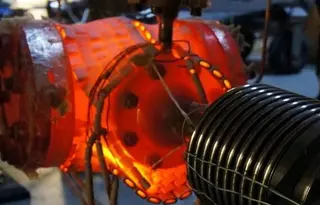

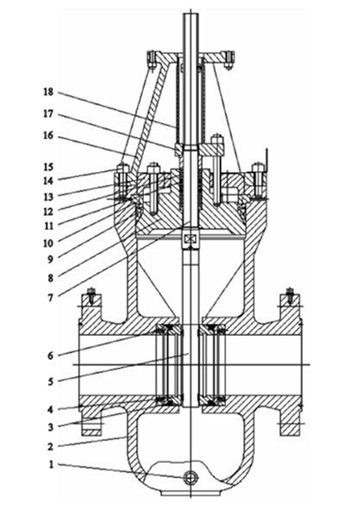

Trunnion-Mounted Ball Valves provide smooth and reliable operation even under high line pressure. Precisely aligned bearings enable low-torque operation, while the trunnion-supported ball remains fixed yet free to rotate, ensuring stability and optimal sealing. All cast trunnion ball valves feature high-quality castings and a fire-safe design, certified according to BS 6755, API 607, and API 6FA, and comply with all relevant ASME standards. Cast steel trunnion ball valves are available in two-piece split body and three-piece bolted body configurations. They are designed and manufactured according to the latest international standards, including API 6D, ASME B16.34, BS 5351, or equivalent specifications. Standard features include fire-safe construction, anti-static design, and blowout-proof stem for enhanced safety, reliability, and durability.

Technical Specification

» Product: Trunnion Mounted Ball Valve

» Size Ranges: NPS 2–48 Inch (DN50–DN1200)

» Temperature Range: -46°C to 120°C

» Design Pressure: Class 150–2500 LB (PN10–PN420)

» Materials: Cast Carbon Steel, Stainless Steel, Duplex, or Other Specials

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other specials

» Seat Materials: RPTFE, DEVLON, PEEK

» End Connections: Flanged RF, RTJ, Welded

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face to Face (End to End): ASME B16.10

» Flanged Connection: ASME B16.5, ASME B16.47

» Test and Inspection: API 598, API 6D

» Butt Welded End: ASME B16.25

» Fire Safety: API 607, API 6A

Product Features

» Double Block and Bleed (DBB): Provides secure isolation for maintenance and safety

» Low Operating Torque: Ensures smooth and easy operation

» Emergency Sealing Device: Offers additional protection in critical situations

» Fireproof Structural Design: Complies with fire safety requirements

» Anti-Static Construction: Prevents static discharge

» Reliable Seat Sealing: Ensures leak-tight performance

» Single Sealing: Automatic pressure relief in the middle cavity of the valve

» Double Sealing: Double-piston configuration for enhanced safety

» Safety Relief Device: Protects against overpressure conditions

» Special Structure for Automatic Pressure Relief Towards Upstream: Optimized for process safety

» Blowout-Proof Stem: Prevents stem ejection under pressure

» Corrosion and Sulfide Stress Resistance: Suitable for harsh chemical environments

» Optional Locking Device or Stem Extension: For added security and operational flexibility

» Optional Direct Mounting to ISO 5211: Compatible with actuators

» Full Port or Reduced Bore: Available to match flow requirements

Send your message to this supplier

Related Articles from the Supplier

How Does a High Performance Butterfly Valve Work

- Dec 14, 2024

High-Temperature Ball Valves Material Selection

- Dec 17, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/high-pressure-trunnion-ball-valve-a105n-2-48-in-cl150-2500.html