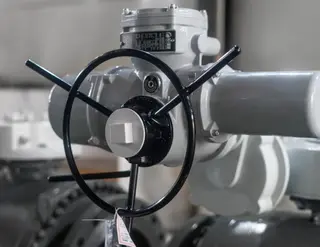

Electric Floating Ball Valve, A105N, 1 Inch, CL400, Flanged

Product Name: Electric Floating Ball Valve

Type: Floating Ball Valve

Body Material: ASTM A105N, Forged Carbon Steel

Size: 1 Inch, DN25, 25 mm

Pressure: Class 400 LB, PN64

End Connection: Flanged

Operation: Electric Actuator

Temperature Range: -46°C to 120°C

Medium: Water, Gas, Oil, etc.

Forged Floating Ball Valves feature a design in which the ball is supported by two PTFE seats, one upstream and one downstream. Upstream line pressure forces the ball against the downstream seat, creating a tight seal and ensuring reliable shutoff. All floating ball valves are produced using high-quality castings and incorporate a fire-safe design certified in accordance with BS 6755, API 607, and API 6FA. These valves comply with all applicable ASME standards. Floating Ball Valves are available in one-piece uni-body, two-piece split-body, and three-piece bolted-body configurations. They are designed and manufactured to the latest international standards, including API 6D, ASME B16.34, and BS 5351, or equivalent specifications. Standard features include fire-safe construction, anti-static design, and a blowout-proof stem.

Technical Specification

» Product: Cast Floating Ball Valve

» Size Ranges: NPS 1/2-10 Inch (DN15-DN250)

» Design Pressure: Class 150-600 LB (PN10-PN100)

» Materials: Cast Carbon Steel, Stainless Steel, Duplex, or Other Specials

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other specials

» Seat Materials: NYLON, RPTFE, PEEK

» Ends Connections: FF and RF flange, Welded

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face to Face (End to End): ASME B16.10

» Flanged Connection: ASME B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded End: ASME B16.25

» Fire Safety: API 607, API 6A

Product Features

» Low operating torque for smooth and efficient operation

» Emergency sealing device for enhanced safety

» Fireproof (fire-safe) structure design

» Anti-static design to prevent electrostatic discharge

» Reliable seat sealing structure ensuring tight shutoff

» Special structure for automatic upstream pressure relief

» Blowout-proof stem with stem flyout prevention design

» Corrosion and sulfide stress cracking resistance

» Optional locking device or stem extension

» Optional direct mounting in accordance with ISO 5211

» Full-port or reduced-bore design options

Send your message to this supplier

Related Articles from the Supplier

Electric Ball Valves: On–Off vs. Modulating Types

- Jan 20, 2026

Installation and Maintenance of Electric Ball Valves

- Dec 14, 2024

Disassembly and Maintenance of Electric Ball Valves

- Sep 03, 2025

How to Choose the Right Electric Ball Valve?

- Dec 16, 2025

Guide to Valve Electric Actuator Selection

- Nov 05, 2025

What is Explosion-Proof Electric Ball Valve

- Dec 22, 2025

Related Articles from China Manufacturers

Electric Actuator Has Advantages

- Jun 20, 2016

Electric Butterfly Valve Introduction

- May 10, 2017

Introduction to Electric PVC Ball Valves

- Dec 10, 2020

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/electric-floating-ball-valve-a105n-1-inch-cl400-flanged.html