Manufacturing Process of Cylindrical Forgings

In modern industrial production, cylindrical forgings play an indispensable role, especially in high-pressure vessels such as hydrogenation reactors and nuclear steam generators. These devices operate under long-term high-temperature and high-pressure conditions, placing extremely high demands on the strength and reliability of the vessels. The quality of cylindrical forgings directly determines whether pressure vessels can meet design standards. Therefore, it is particularly important to study their production process in depth and improve product quality.

Overview of Cylindrical Forging Processes

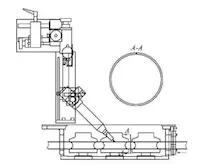

The forging process of cylindrical forgings mainly includes the following steps: cutting, upsetting, piercing, mandrel stretching, mandrel expansion, leveling, and final product machining. Each step is closely related, and the completion quality of the previous heat directly affects the progress and quality of the next heat. Therefore, in quality control, strict inspection must be conducted at every stage of forging to ensure the final product's quality.

1. Cutting

Cutting is the first step in the forging process, and its quality directly affects subsequent processes. When cutting, it is essential to ensure that the billet surface is smooth to prevent folding or damage during the subsequent upsetting process. For steel ingots directly cut by gas, the cut surface should be flat. In addition, the material requirement should be reasonably calculated according to the final size and shape of the forging to improve material utilization and reduce waste.

2. Upsetting

Before upsetting, the billet should be straightened to ensure it is flat in two perpendicular directions. This step is crucial for ensuring billet uniformity and the quality of subsequent processes. During upsetting, deformation force and heating temperature must be strictly controlled to prevent cracks or other defects in the billet.

3. Piercing

Piercing is one of the key steps in cylindrical forging. Due to the large tonnage of billets, the size of the punch is also large, making alignment difficult. Whether the punch is aligned during piercing directly affects the quality of the mandrel stretching in the next heat. If the hole is misaligned, the wall thickness of the billet will be uneven, resulting in long and short sides in the next heat, which affects the quality of the final product. Therefore, during piercing, the position and force of the punch must be precisely controlled to ensure the symmetry and uniformity of the hole.

4. Mandrel Stretching

During mandrel stretching, the billet is axially elongated. After stretching, both ends must be flush, with no unformed areas, and the surface should be smooth, meeting process dimension requirements. Common problems include serious uneven length, end cracks and burrs extending into the inner hole, transverse cracks in the inner hole, and uneven wall thickness. Based on production experience, the following measures are taken: for forgings longer than 4000 mm, pre-stretching steps are generally required to prevent serious long and short sides and inner hole cracks due to excessive stretching. During pre-stretching, reduction must be strictly controlled to ensure efficiency, and burrs and cracks at the ends must be cleaned after pre-stretching. Before mandrel stretching, the distance from the billet to the mandrel flange root should be determined based on the reduction amount, and it should not be too large or too small. If the distance is too small, a flash may remain at the end. During stretching, the billet feed should also be monitored, and the reduction adjusted flexibly according to production experience.

5. Mandrel Expansion

Expansion is the key step to increase the billet's diameter. When expanding, the appropriate mandrel should be selected according to the inner hole size, and the mandrel spacing should be appropriate. During expansion, the reduction should be uniform, the rotation angle proper, and both ends should feed as synchronously as possible. When approaching final dimensions, small reductions should be used to ensure expansion efficiency, with reasonable hammer overlap and no unformed areas, resulting in a smooth surface. During mandrel expansion, each pass has a relatively small reduction, making it difficult for oxide scale to fall off, especially for hydrogenation cylinder sections with highly adherent scale. If not removed in time, the oxide can be pressed into the billet and affect forging quality. Therefore, before forging, measures should be taken to remove oxide from the billet surface, such as timely replacement of heating furnace supports, controlling billet heating time, using hammer head rotation under the press to remove surface oxide, and using the mandrel to remove oxide from the inner hole.

6. Leveling

Leveling to process dimensions is an important step to ensure the final quality of the forging. During leveling, it is necessary to observe the billet feed at both ends. For billets with large leveling amounts (>600 mm), leveling on both sides is required; otherwise, the billet will flare, severely affecting subsequent expansion. During leveling, the equipment parameters should be reasonably adjusted according to the specific requirements and dimensions of the forging to ensure flatness and dimensional accuracy.

7. Final Product Machining

During final product machining, the shrinkage of the forging diameter should be considered. If the product undergoes subsequent heat treatment such as quenching and tempering, the effect on forging dimensions must also be taken into account. After comprehensive consideration, determine the dimensions of the forging in the hot state. During final machining, surface treatment and quality inspection must also be conducted to ensure that the final product meets design requirements and quality standards.

Key Considerations for Cylindrical Forging Quality Control

Every stage of cylindrical forging is crucial, and any problem may affect the final product quality. Therefore, quality control runs throughout the entire forging process, from raw material selection to final product inspection, with strict control at every step. Key points include:

1. Raw Material Selection

The quality of raw materials directly affects the final product. Forging materials include various steel grades, high-temperature alloys, and non-ferrous metals such as aluminum, magnesium, titanium, and copper. Most selected materials comply with national standards, while some are new materials under research, trial, or promotion. When selecting raw materials, the most suitable materials must be chosen according to process requirements and product usage conditions, ensuring that raw material quality meets relevant standards and specifications to prevent product nonconformity.

2. Heating Control

Heating reduces forging deformation force and improves metal plasticity but can cause oxidation, decarburization, overheating, and burning. Accurate control of start and finish forging temperatures significantly affects the product's structure and performance. Flame furnace heating is cost-effective and widely applicable but has long heating times, high oxidation, and decarburization, and labor conditions need continuous improvement. Induction heating is rapid and has less oxidation but has poor adaptability to shape, dimension, and material changes. Therefore, heating methods and process parameters should be reasonably chosen according to production conditions and product requirements to ensure heating quality.

3. Deformation Force Calculation and Equipment Selection

Forging shaping occurs under external forces; therefore, accurate calculation of deformation force is an important basis for selecting equipment and die verification. Stress-strain analysis within the deforming body is also indispensable for optimizing the process and controlling the microstructure and performance of cylindrical forgings. Analysis methods include principal stress, slip-line, upper-bound, and finite element methods. The principal stress method is simple and intuitive but not very rigorous; it can calculate total load and stress distribution at the workpiece-tool interface. The slip-line method is rigorous for plane strain problems and intuitively solves local deformation stress distribution but has limited applicability. The upper-bound method gives overestimated loads, and upper-bound finite elements can also predict shape changes during deformation. Finite element methods can provide external load, workpiece shape changes, and internal stress-strain distribution but require significant computing time, especially for elastic-plastic solutions. Recently, combined methods are increasingly used, such as rough calculation with the upper-bound method and detailed finite element analysis at critical points. Reasonable selection of deformation force calculation methods and equipment can effectively improve forging efficiency and product quality.

4. Lubrication and Friction Control

Reducing friction not only saves energy but also improves die life. Uniform deformation helps improve the microstructure, so lubrication is an important measure to reduce friction. Lubricants vary according to forging methods and working temperatures. Glass lubricants are commonly used for high-temperature and titanium alloy forgings. Water-based graphite is widely used for hot steel forging. Cold forging often requires phosphate or oxalate treatment due to high pressure. In production, appropriate lubricants and methods should be selected according to forging processes and working conditions to reduce friction and improve forging quality and efficiency.

Post-Forging Treatment and Precautions

- Heat Treatment: Post-forging heat treatment is crucial for ensuring forging performance. Heat treatment improves microstructure, mechanical, and physical properties to meet service requirements. Processes include annealing, normalizing, quenching, and tempering, chosen according to material, shape, size, and usage. Heating temperature, holding time, and cooling rate must be strictly controlled to ensure quality.

- Forging Placement and Storage: After forging, billets should ideally be placed vertically to prevent deformation under gravity. For large forgings, storage environment and conditions must be considered to prevent rust or damage. Regular inspections should be conducted to ensure stable quality during storage.

Conclusion

Cylindrical forgings are widely used in high-pressure vessels such as hydrogenation reactors and nuclear steam generators, and their quality directly affects equipment safety and reliability. Through in-depth study and optimization of the forging process, the quality and performance of cylindrical forgings can be effectively improved. In production, strict control of every forging step is required, from raw material selection, heating control, deformation force calculation, lubrication and friction control, to billet forming method selection. Additionally, post-forging heat treatment and storage conditions must be considered to ensure the final product quality.

Send your message to this supplier

Related Articles from the Supplier

Manufacturing Process of Cylindrical Forgings

- Jan 21, 2026

Lost-Wax Casting: The Art of Precision Manufacturing

- Aug 19, 2025

Related Articles from China Manufacturers

Manufacturing Process of Forged Valve Bodies

- Oct 17, 2024

Manufacturing Process of Reducing Flange Mold

- Aug 08, 2015

Manufacturing Process of Thick-wall Welded Pipe

- May 06, 2020

The Manufacturing Process of Industrial Valves

- Aug 13, 2017

The Manufacturing Process of FBE Anti-corrosion Pipe

- Jul 18, 2016

The Process Route of Valve Manufacturing

- Jul 05, 2016

Related Products Mentioned in the Article

Supplier Website

Source: http://www.forging-casting-stamping.com/manufacturing-process-of-cylindrical-forgings.html