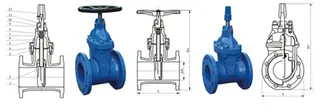

Non Rising Stem Resilient Seated Gate Valves, Cast iron, Ductile iron

Key Specifications / Features

Detail Information

The valves disc is rubber-packed to get excellent sealing effect by the rubber's resilient deformation. Non-rising resilient seated gate valves solve the problem in general gate valves such as leakage, rusting etc. and saves installation space. It is used widely in tap water industry, sewage treatment, shipping construction, petroleum, chemicals, food, pharmacy, textile, electric power, metallurgy and energy system's pipeline to adjust and shut off fluids.

Technical Parameters

Nominal pressure: 1.0-2.5MPa

Working temp.:0-120°C

Flanged end: GB/T17241.6 GB9113

Nominal diameter: 50-400mm

Service: water, Sewage, oils, gas etc.

Inspection and test: API 598

Materials

| Serial no. | part | material |

| 1 | Body | Grey cast iron, ductile cast iron, cast steel |

| 2 | Disc | Ductile cast iron packed with rubber or EDPM outside |

| 3 | Bolt | Carbonized treatment |

| 4 | Gasket | Buna-N rubber or EDPM |

| 5 | Cover | Grey cast iron, ductile cast iron, cast steel |

| 6 | Stem | stainless steel |

| 7 | O-ring | Buna-N rubber or EPDM |

| 8 | Thrust bearing | Gun metals |

| 9 | Bolt | Stainless steel |

| 10 | Gland | ductile cast iron, cast steel |

| 11 | Dust proof gasket | Buna-N rubber |

| 12 | Hand wheel(transmission cap) | Cast iron |

Dimensions

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 |

| H (min)(full close) | 313 | 332 | 372 | 424 | 497 | 562 | 680 | 837 | 948 | 1010 | 1220 | 1280 | 1480 | 1665 |

| H (max)(full open) | 355 | 375 | 415 | 476 | 540 | 600 | 720 | 875 | 990 | 1050 | 1245 | 1310 | 1560 | 1750 |

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.