Rising Stem Knife Gate Valve, A351 CF8M, DN100, PN10, 4 Inch

Key Specifications / Features

Detail Information

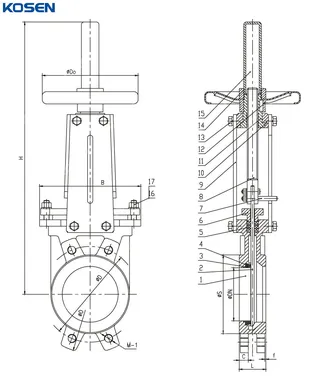

Product Name: Rising Stem Knife Gate Valve

Features: Rising Stem, Unidirectional

Body Material: ASTM A351 CF8M

Size: DN100, 4 Inch

Pressure: PN10, Class 150 LB

End Connection: Wafer

Operation: Handwheel

The manual knife gate valve is a unidirectional wafer knife edge gate valve designed for on-off operations in industrial pipelines. Its body and seat structure prevents clogging, ensuring reliable shutoff even with fine particles in the flow. The beveled knife edge allows the gate to easily cut through thick media. To meet various working conditions, the following types of knife gate valves are available:

» Non-rising stem knife gate valve

» Wafer knife gate valve

» Lugged knife gate valve

» Pneumatic knife gate valve

» Electric knife gate valve

» Manual knife gate valve

» Bevel gear knife gate valve

Technical Specification

» Structure: Unidirectional Wafer Knife Wedge Gate Valve

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: PN10, PN16, Class 150 LB

» Max Working Pressure:

DN50 to DN250: 10 bar

DN300 to DN450: 7 bar

DN500 to DN600: 4 bar

» Body Material: Ductile Iron, Carbon Steel, Stainless Steel, Special Alloys, etc.

» Disc Material: Stainless Steel Chrome Plated, Special Alloys, etc.

» Seat Material: Stainless Steel + STL, EPDM (120°C), Viton (200°C), PTFE (200°C), NBR (80°C)

» Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN 1092-1

» Face to Face: MSS SP-81

» Applications: Pulp & Paper, Water Treatment, Beverage & Food, Fine Chemicals, Power Plants, Steel Industry, etc.

» Temperature Range: -29°C to +538°C

Product Features

» High Flow Capacity: Achieves low load loss. The gate's rounded edges prolong the working life of the rings and packing.

» Correct Mounting Indicator: A directional arrow on the body indicates the correct mounting position.

» Versatile Drive Options: Equipped with a protector tube, the valves offer interchangeable drives between handwheel and pneumatic actuator.

» Corrosion Protection: Coated with epoxy paint to protect against corrosion. Suitable for water with up to 5% concentration of solid particles.

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.