Rising Stem Gate Valve, API 602, ASTM A105N, 1 IN, CL600, RF

Key Specifications / Features

Detail Information

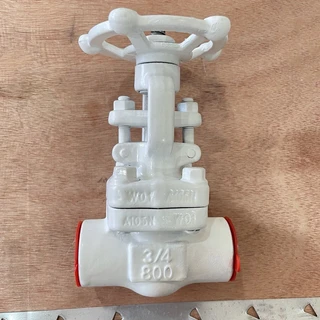

Product Name: Rising Stem Gate Valve

Design Standard: API 602

Body Material: ASTM A105N

Size: 1 Inch, DN25

Pressure: Class 600 LB, PN100

End Connection: RF Flanged

Operation: Handwheel

Forged Steel Gate Valves are meticulously designed and manufactured to meet international standards, including API 602, ASME B16.34, and DIN 3202, or their equivalents. Featuring a compact yet exceptionally sturdy design, these valves are ideal for high-pressure, high-temperature applications. The optional solid CoCr alloy wedge ensures low friction and extends the valve's service life.

The packing rings are precompressed to 4000 psi to provide a reliable, high-integrity seal. For welded bonnet valves, the bonnet is threaded and torqued to an engineered value, with the body-bonnet joint strength-welded to offer double protection against leakage. Additionally, the fully guided wedge reduces wear on the seating surfaces, enhancing performance. Optional designs include double packing, leak-off connections, live-loading, and packing blowout for easy packing removal, providing flexibility and ease of maintenance.

Technical Specification

» Size Range: 1/2-2 Inch (DN15-DN50) (for Forged Items)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials:

Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, etc

ASTM A105N, A350 LF2, A182 F11, F22, F304, F304L, F316, F316L

» Trim Materials: 13%Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, and other specials

» End Connections: SW, FNPT, BW, RF, RTJ, Grooved

» Design and Manufacture: ASME B16.34, API 602

» Face to Face (End to End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded Ends: ANSI B16.5

» Threaded Ends: ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

» Temperature Range: -29°C to 595°C

» Medium: Water, Gas, Oil, etc.

Product Features

- OS&Y (Outside Stem and Yoke) design

- Metal-sealed (API Trim #1, #5, #8, #10, etc.)

- Optional locking device or stem extension

- Available with bolted bonnet, welded bonnet, or pressure-sealed bonnet

- Optional direct mounting to ISO 5211

- Full bore or reduced port options

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.