DIN Safety Relief Valve, ASTM A216 WCB, DN50, PN16, 2 IN, RF

Key Specifications / Features

The DIN Safety Relief Valve Plant in China features an ASTM A216 WCB carbon steel body, ensuring durability and reliability. With a DN50 (2-inch) size and a pressure rating of PN16 (Class 150 LB), it is designed for high-performance applications. The valve has RF flanged ends, making it easy to integrate into existing systems. Suitable for use in steam, air, and other media, this valve offers robust safety and efficiency for industrial processes.

Detail Information

Product Name: DIN Safety Relief Valve

Design Standard: DIN Standard

Body Material: ASTM A216 WCB

Size: DN50, 2 Inch

Pressure: PN16, Class 150 LB

End Connection: RF Flanged

Medium: Steam, Air

The 900 series DIN standard spring-loaded safety valves are primarily utilized in industries such as petroleum and natural gas, chemistry, electricity, metallurgy, and combustion gas. These valves serve as overpressure protection devices, offering high precision in operation, excellent reseating capabilities, and rapid opening and closing actions. They are designed for ease of operation and maintenance.

Technical Specification

» Normal Size Range: DN20-DN300

» Nominal Pressure Range: PN16-PN40

» Design and Testing: according to DIN standards

» Flange Standards: EN 1092

» Material Selection: Carbon Steel, Stainless Steel, Alloy Steel, and other special materials

» End Connections: RF flanged and groove flange options

» Throat Diameter: Large discharge capacity

» Seat Design: Half-seat structure

» Modular Design: Components are designed with a modular board system

» Seal Options: Available with soft seals, corrugated seals, and radiating frame structures as per user requirements

» Working Medium: steam and air

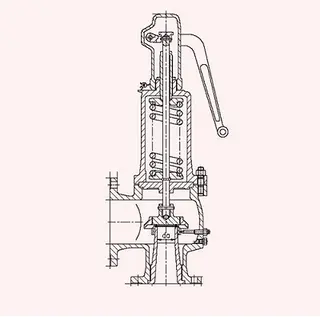

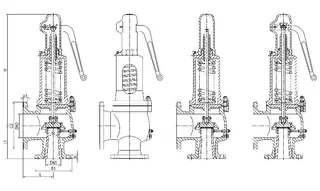

Structural Diagram

Product features

A full-lift safety valve is designed so that the disc lifts sufficiently to ensure that the curtain area no longer affects the discharge area. The discharge area, and consequently the valve's capacity, is determined by the bore area. This configuration is achieved when the disc lifts a distance of at least a quarter of the bore diameter. For general steam applications, a full-lift conventional safety valve is often the optimal choice. The opening height of a full-lift safety valve is more than one-fourth of the flow diameter, which significantly enhances its discharge capacity. This feature provides a substantial advantage in terms of efficient and rapid release of pressure.