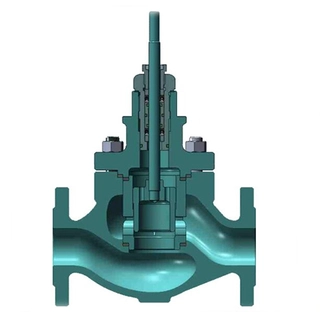

Non-Lubricating Globe Control Valve, 1-4 IN, 150-600 LB, WCB

Key Specifications / Features

Detail Information

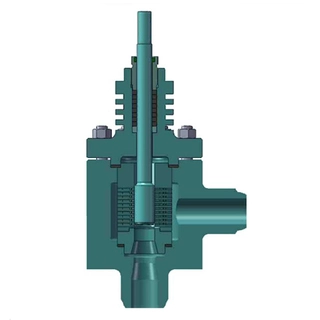

Product Name: Cage-guided Globe Control Valves

Key Features: Cage-guided, Non-lubricating, Globe Style

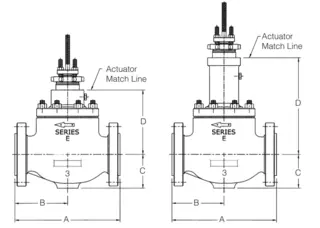

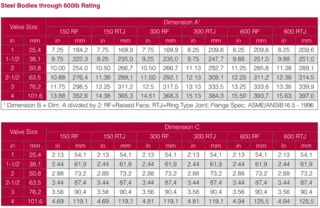

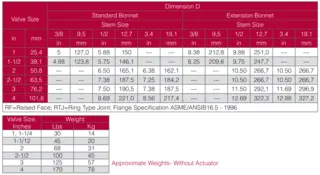

Size Range: 1 Inch - 4 Inch, DN25-DN100

Pressure: Class 150 LB - 600 LB

Body Materials: ASTM A352 LCC, ASTM A216 WCB, WCC, ASTM A217 WC9, C5, Monel, ASTM A351 CF8M SST.

Trim Materials:

Standard Material: Stainless Steel, SS 316.

Optional Material: Alloy 6, Cobalt, Tungsten Carbide.

Seats: Metal and TFE

Shutoff: Class IV & V

Flow Characteristics:

Linear

Quick Opening

Equal Percentage

Noise Abatement

Anti-Cavitation

Flow Direction: Flow Up Through the Seat Ring.

Features & Benefits

1. Offers characterized flow options such as equal percentage, linear, and quick opening.

2. Available in various body and trim materials to suit diverse applications.

3. Features quick-change trim for easy maintenance.

4. Optional NACE MRO 175 / ISO 15156-2009 for sour service capability.

5. Ensures tight shutoff for reliable operation.

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.