Impact Sampling Methods for Thin-Walled Austenitic Stainless Steel Seamless Pipes

Abstract: ASTM A370-2022 requires surface removal for impact specimens, which conflicts with ASME B31.3-2022, where undercooling must be considered if the notch width is less than 80% of the material thickness. Based on this, the present study examines sampling methods for impact specimens of thin-walled austenitic stainless steel seamless pipes. Impact tests were performed on specimens in both the as-received (solution-annealed) and flattened conditions. The results showed that the impact energy absorbed by the flattened specimens was significantly higher than that of the as-received specimens. Hardness tests were conducted at three positions along the same flattened specimen: the end, one-quarter width (1/4 W), and one-half width (1/2 W). The results showed that hardness at the 1/4 W position was the lowest. The ferrite number of specimens in both the as-received and flattened conditions was also measured, showing that the ferrite number in the flattened specimens was significantly higher. Further hardness tests were conducted at the 1/4 W position for both the as-received and flattened specimens at room temperature and −196 °C. The results showed that the flattened specimens exhibited higher hardness than the as-received specimens at both temperatures. Analysis indicates that strain hardening during the flattening process is the dominant factor at −196 °C and is the primary cause of this behavior. For thin-walled austenitic stainless steel seamless pipes, impact test results obtained directly from as-received specimens—without the surface removal specified in ASTM A370—are more representative and also meet the undercooling requirements of ASME B31.3-2022. Austenitic stainless steel, owing to its face-centered cubic austenite phase, retains excellent low-temperature toughness even at extremely low temperatures, exhibiting only a slight ductile-to-brittle transition. This makes it an ideal structural material for cryogenic applications, with service temperatures reaching as low as liquid helium. Low-temperature impact testing is typically conducted to verify that the material retains adequate impact toughness under these conditions. According to GB 150-2011, “impact testing is not required for austenitic steels operating at temperatures above −196 °C. For the temperature range from −196 °C to −253 °C, impact testing requirements should be specified in the design documents. Additionally, carbon steel pipes with a wall thickness of less than 6.5 mm are exempt from impact testing due to sampling difficulties. Despite this, designers or purchasers often require low-temperature impact testing at −196 °C (liquid nitrogen temperature) for certain thin-walled (less than 5 mm) austenitic stainless steel seamless pipes, based on their specific operating conditions. However, no current standards or specifications offer clear guidance on sampling thin-walled seamless pipes. ASTM A370-2022, Section 23.2.2.3, states that if it is not possible to prepare a full-size standard specimen, a small specimen as large as possible should be used. The impact specimen must be machined, removing at least 0.5 mm of material from the surface. Meanwhile, ASME B31.3-2022, Section 323.4(b), specifies that for materials with a Charpy V-notch thickness of less than 10 mm, if the notch width is at least 80% of the material thickness, the impact test should be conducted at a temperature no higher than the design minimum; otherwise, undercooling must be considered. When these requirements are combined, low-temperature impact testing of thin-walled pipes must take undercooling into account. For example, for seamless pipes with a 4 mm wall thickness, impact specimens prepared according to ASTM A370 can only be machined to a thickness of 2.5 mm to satisfy the surface removal requirement. This is less than 80% of the original material thickness, so undercooling must be considered in accordance with ASME B31.3-2022. The combination of these two standards creates a conflict. Furthermore, for materials with a design temperature of −196 °C, such as those used in liquid ammonia service, conventional liquid nitrogen cooling methods cannot fully account for undercooling.

Given the curved geometry of seamless pipes, the effect of curvature on material removal at each location must be taken into account. This makes it difficult to meet the surface removal requirements specified in ASTM A370-2022 during specimen preparation. Therefore, the proposed approach is to disregard surface removal and perform the impact test directly on the as-received material (solution-annealed, unflattened, and without any surface removal). Two sampling schemes were employed: impact specimens obtained directly from seamless pipes and specimens prepared from flattened pipes. It was initially assumed that plastic deformation during flattening would transform the austenite structure into deformed martensite. Since martensite is brittle at low temperatures (−196 °C), it was expected to reduce the impact energy absorbed during testing, thereby decreasing impact toughness and yielding conservative results. However, the test results showed that the flattened specimens absorbed significantly more impact energy than the as-received specimens, contradicting this assumption. Consequently, a comparative study was conducted to investigate the reasons for the differences between the two sampling methods and to address the challenges of impact testing thin-walled pipes, particularly in meeting the undercooling requirements of ASTM A370-2022 and ASME B31.3-2022.

1. Test Section

1.1 Test Equipment and Instruments

PBM2000 Pendulum Impact Tester

HRS-50 Rockwell Hardness Tester

FERITSCOPE FMP30 Ferrite Meter (HELMUT FISCHER GMBH)

WZPK3365P100 Cryogenic Impact Test Apparatus

1.2 Test Method

TP316L stainless steel seamless pipes (60.3 mm × 3.91 mm) and TP304L stainless steel seamless pipes (88.9 mm × 3.05 mm) were selected for this study. Specimens were cut from both the as-received and flattened pipes using wire cutting. Impact tests were conducted at −196 °C (liquid ammonia temperature) at one-quarter of the specimen width (1/4 W) of the seamless pipe. The differences in impact energy absorption between specimens in different conditions were analyzed. Surface removal was not applied to the as-received specimens, while it was minimized for the flattened specimens. To investigate the reasons for the differences in impact energy absorption between the two conditions, the following test plan was implemented. A total of eight seamless pipes of TP304L and TP316L were selected for comparative testing in the as-received and flattened states. The main test items included:

Hardness Tests at Different Positions

Hardness was measured at multiple positions on the flattened specimens to observe positional variations and determine the strain-hardening trend.

Ferrite Measurement

Considering that austenite is paramagnetic and martensite is ferromagnetic, a ferrite meter was used to estimate the proportion of deformation-induced martensite in austenitic stainless steel by measuring ferrite content based on magnetic permeability.

Cryogenic Hardness Tests

Hardness was measured at a fixed position on the specimen to determine the strain-hardening trend at room temperature.

The specimen was then held at −196 °C for at least 10 minutes, and hardness was measured immediately to assess changes under low-temperature conditions, which were subsequently compared with the room-temperature results.

2. Test Results and Analysis

2.1 Comparison of Impact Absorption Energy for Samples in Different States

Impact tests were conducted on TP316L and TP304L stainless steel seamless pipes in both the as-received and flattened conditions, following the described test method. The results are summarized in Table 1. As shown, for both types of stainless steel seamless pipes, the flattened specimens exhibited greater impact absorption energy than the as-received specimens.

Table 1. Impact Test Results of Seamless Steel Pipes in As-Received and Flattened States

|

Material Grade |

Impact Specimen Dimensions (mm) |

Impact Absorbed Energy in As-Received State (J) |

Impact Absorbed Energy in Flattened State (J) |

|

Measured Value |

Average Value |

||

|

TP316L |

3.3 × 10 × 55 |

46.0, 47.2, 44.8 |

46 |

|

TP304L |

2.5 × 10 × 55 |

40.3, 41.5, 41.1 |

41 |

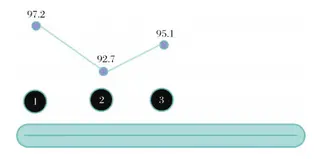

2.2 Comparison of Hardness at Different Positions of Flattened Specimens

Hardness tests were conducted at three positions along the same flattened specimen: the end (position 1 in Figure 1), one-quarter width (1/4 W, position 2), and one-half width (1/2 W, position 3). The results are shown in Figure 1. As illustrated, the hardness at the 1/4 W position is the lowest, indicating that strain hardening is less pronounced at this location than at the end and 1/2 W positions. Therefore, the 1/4 W position, where strain hardening is minimal, was selected for the flattened impact tests.

Figure 1 Schematic diagram of hardness test results at different positions of a flattened specimen (HRB)

2.3 Comparison of Ferrite Counts in Samples under Different Conditions

Ferrite counts of TP316L and TP304L stainless steel seamless pipes were measured in both the as-received and flattened states using a ferrite analyzer. The results are presented in Table 2. The ferrite counts of the flattened specimens are higher than those of the as-received specimens, although the difference is minimal. This indicates that during flattening, only a small portion of austenite transforms into magnetic martensite, and the content of deformation-induced martensite remains extremely low. Consequently, at −196 °C, the presence of phases affecting low-temperature impact toughness is negligible.

Table 2 Ferrite Number Determination Results of Seamless Steel Pipes in As-Received and Flattened States

|

Material Grade |

Specification (mm) |

Ferrite Number (FN) As-Received |

Ferrite Number (FN) Flattened |

|

TP304L |

26.7 × 2.77 |

0 |

0.8 |

|

TP304L |

26.7 × 2.77 |

0 |

0.5 |

|

TP304L |

26.7 × 2.11 |

0.1 |

0.1 |

|

TP304L |

33.4 × 3.91 |

0.1 |

0.6 |

|

TP316L |

26.7 × 2.77 |

0.1 |

2.2 |

|

TP316L |

21.3 × 2.77 |

0.1 |

0.1 |

|

TP316L |

21.3 × 2.77 |

0 |

0.1 |

|

TP316L |

26.7 × 3.91 |

0 |

0.1 |

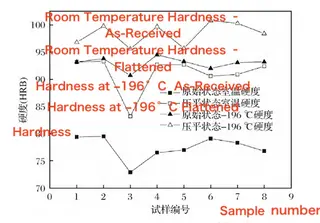

2.4 Comparison of Hardness of Specimens under Two Conditions at Different Temperatures

Hardness tests were conducted on the as-received and flattened specimens described in Section 2.3 at the 1/4 W position, both at room temperature and at −196 °C, to evaluate the degree of strain hardening in the two states. The results are presented in Figure 2. At room temperature, the flattened specimens exhibited significantly higher hardness values than the as-received specimens, averaging approximately 20% greater, indicating substantial strain hardening. At −196 °C, the hardness values of all specimens increased compared with those at room temperature. The flattened specimens remained harder than the as-received specimens, averaging approximately 5% greater. This increase is smaller than that observed at room temperature, suggesting a reduced relative contribution of strain hardening at cryogenic temperatures.

Figure 2 Comparison of hardness for as-received and flattened specimens at different temperatures (HRB)

2.5 Analysis and Discussion

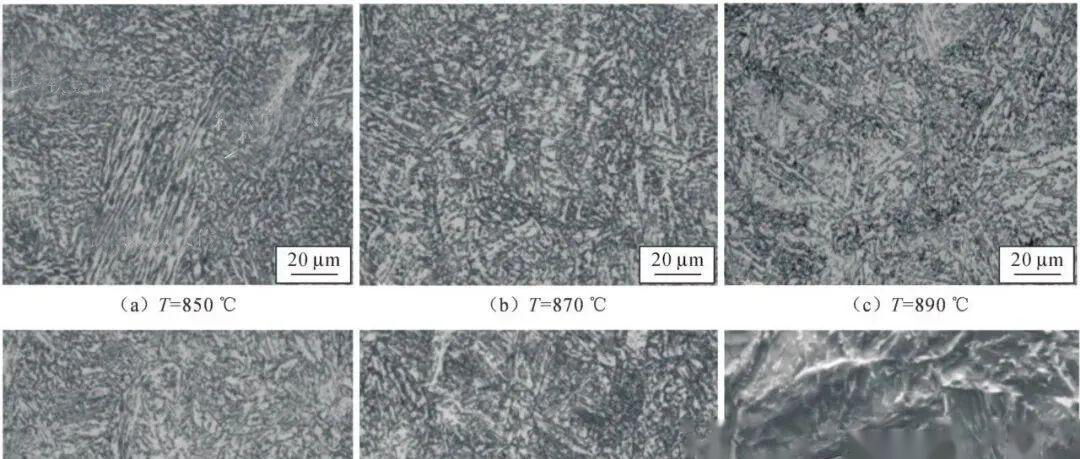

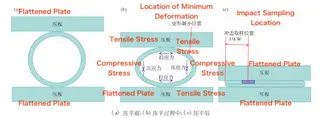

Some scholars have observed that once the prestrain reaches a certain level, S30408 stainless steel undergoes a deformation-induced martensitic transformation. During the flattening of seamless pipes, the total cross-sectional area changes minimally, making it impossible to calculate the prestrain using the area-conservation method. Moreover, plastic deformation is uneven across the pipe, with tensile and compressive stresses partially canceling each other, as illustrated in Figure 3. Consequently, direct calculation of local deformation is not possible. During flattening, deformation is greatest at the ends and the middle of the pipe, and smallest at the 1/4 W position. This observation is supported by the hardness test results at different locations (Figure 1). Therefore, the impact specimens were positioned as close to the 1/4 W location as possible, minimizing the influence of localized deformation on the impact test results. After flattening, ferrite meter readings showed only a slight increase, indicating that the amount of deformation-induced martensite remained extremely low. This suggests that at −196 °C, the microstructural components capable of affecting low-temperature impact toughness are negligible. However, the significant strain hardening induced during the flattening process still dominates even at cryogenic temperatures, consistent with observations of strain-hardening effects on the low-temperature impact properties of 06Gr19Ni10 stainless steel welded joints. Some researchers have suggested that temperature-induced stresses and volume changes during rapid cooling can induce a small amount of deformation-induced martensitic transformation. This may explain why the hardness measured in the −196 °C impact tests was higher than that at room temperature. However, the magnetic microstructure of the specimens at −196 °C could not be measured using a ferrite meter, and thus the influence of low-temperature deformation martensite could not be directly verified. Therefore, for thin-walled austenitic stainless steel seamless pipes, regardless of ASTM A370 requirements, the effect of low-temperature deformation-induced martensite cannot be conclusively determined. Impact tests performed on as-received specimens avoid the influence of strain hardening induced by flattening. In other words, sampling in the as-received state provides a more accurate representation of the material’s intrinsic toughness.

3. Conclusion

Based on the experimental results and analysis, the following conclusions can be drawn:

- The impact absorption energy of flattened specimens is higher than that of as-received specimens of the same austenitic stainless steel seamless pipe. Analysis suggests that this increase is primarily due to strain hardening.

- By comparing the impact test results of as-received and flattened specimens, it can be concluded that for thin-walled austenitic stainless steel seamless pipes, sampling directly in the as-received state—without applying the surface removal specified in ASTM A370—provides a more representative measure of the material’s intrinsic toughness.

- Additionally, this approach satisfies the undercooling requirements of ASME B31.3-2022.

Figure 3 Schematic diagram of the flattening process of a seamless pipe

(a) before flattening (b) during flattening (c) after flattening

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.steel-pipes.com/news/impact-sampling-methods-for-thin-walled-austenitic-stainless-steel-seamless-pipes.html