What are Double Block and Bleed Ball Valves?

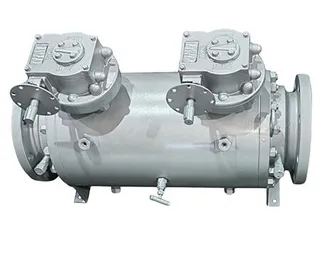

A Double Block and Bleed (DBB) ball valve is a type of valve device made up of two standard ball valves integrated into a single unit. These two ball valves share a common inlet, allowing them to meet the control needs of two separate outlets at the same location. Each outlet can be independently controlled, providing more efficient fluid control. The DBB ball valve is widely used in various pipeline systems, especially in natural gas pipelines, due to its simple structure and ease of operation. Compared to traditional valve systems, the DBB ball valve offers significant advantages in sealing performance, operational convenience, and system safety.

Working Principle of DBB Ball Valves

The design of the DBB ball valve integrates two standard ball valves into a single unit, replacing the complex connections between multiple valves. The DBB ball valve uses the Double Block and Bleed (DBB) function, which effectively prevents leaks and quickly shuts off and discharges the pipeline. The working principle is as follows.

Shut-off and Bleed: One of the ball valves rotates to cut off the flow of fluid in the pipeline. The other ball valve acts as a seal, which only fails in the event of a malfunction. This design provides dual protection and shut-off effects, extending the valve's lifespan by alternating the use of both ball valves.

Easy Installation: During installation, the DBB ball valve does not require adjustment of the fluid centerline. The two high-pressure ball valves can be directly installed in series. This avoids connection points and reduces the risk of leakage, simplifying the installation process and reducing system complexity.

Sealing Design and Performance of DBB Ball Valves

One of the key features of the DBB ball valve is its excellent sealing performance. The sealing system is well-designed to maintain a long-term seal, even under high pressure and high flow conditions. The specific design features are as follows.

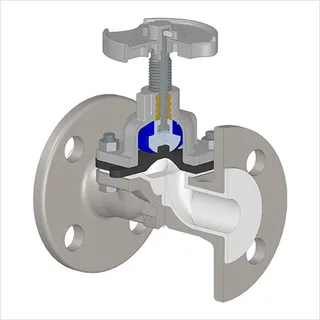

Reverse Sealing Structure: The valve stem is equipped with a sealing gasket and uses a reverse sealing design. This structure enhances sealing as the internal pressure of the valve increases, ensuring better sealing performance. It effectively prevents the valve stem from being pushed out by pressure, improving operational safety.

V-shaped Packing: The packing uses a V-shaped structure, which converts the internal pressure and the locking force of the external gland into sealing force on the valve stem. This further improves the sealing performance.

Working Principle and Advantages of DBB Ball Valves

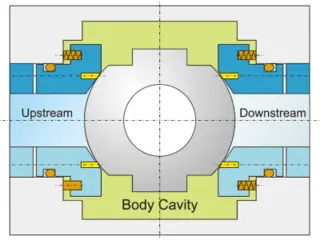

A DBB ball valve typically consists of three ball valves. The middle valve is known as the "bleed" valve, and the two outer valves are the "seal" valves. This design allows maintenance or seal replacement to be performed online without shutting down the entire pipeline system. The working principle is as follows.

Fluid Control: The DBB ball valve controls the flow of fluid by rotating the ball valve. When the ball valve aligns with the pipeline axis, the fluid can flow. When the ball valve rotates to a perpendicular position, the flow is completely cut off, achieving fluid control.

Dual Isolation: The DBB ball valve uses a dual isolation design, which effectively isolates two different media in the pipeline, preventing cross-contamination. This ensures the safety and reliability of the system.

Design Advantages of DBB Ball Valves

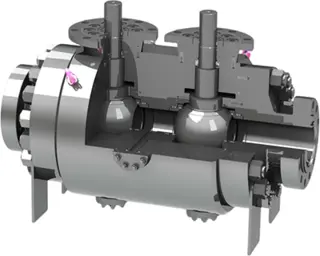

DBB (Double Block and Bleed) ball valves are widely used in industries requiring high safety and reliability, such as oil, gas, chemical, and energy sectors. The design advantages of DBB ball valves are as follows.

Low Fluid Resistance: DBB ball valves have low fluid resistance, reducing energy consumption and operational costs. Compared to traditional valves, DBB ball valves significantly improve fluid flow efficiency.

Excellent Sealing Performance: DBB ball valves use advanced sealing technology to effectively prevent leakage, ensuring the long-term safe and stable operation of pipeline systems.

Corrosion Resistance: DBB ball valves are highly resistant to corrosion, making them suitable for fluid control in corrosive environments. They are particularly useful in industries such as chemical and petroleum.

Simplified Maintenance and Operation: The design of the DBB ball valve makes maintenance easier. Users can perform repairs or replace seals without shutting down the pipeline system. This significantly reduces downtime and improves equipment utilization.

High Safety: The reverse sealing structure and V-shaped packing enhance the safety of the valve under high-pressure conditions. Additionally, the dual isolation feature effectively reduces the risk of leaks, further improving system safety.

Additional Functions and Design Options

In addition to basic fluid control functions, DBB ball valves can be customized to include other features for more complex operating conditions:

Fire-Safe Design: DBB ball valves can be designed with a fire-safe structure to ensure that in the event of a fire, the sealing area forms a metal-to-metal seal even if the seal ring is damaged. This prevents leakage and controls the spread of fire.

Anti-Operation Design: For installations in outdoor or vulnerable locations, DBB ball valves can be equipped with a locking mechanism to prevent safety issues caused by incorrect operation.

Anti-Static Design: DBB ball valves can be designed with anti-static features to prevent static buildup and sparks. This ensures safety when handling flammable media.

Conclusion

The DBB double ball valve plays a crucial role in fluid control systems due to its unique working principle and excellent sealing performance. It not only controls fluid flow effectively but also enhances system safety and reliability. By reducing energy consumption and operational costs, it provides users with significant economic benefits. As technology continues to advance, the use of DBB ball valves in industrial applications will expand, making them an essential component in various pipeline systems.

Send your message to this supplier

Related Articles from the Supplier

What are Double Block and Bleed Ball Valves?

- Dec 27, 2024

What are Eccentric Segmented Ball Valves?

- Aug 27, 2025

What are Diaphragm Valves?

- Dec 30, 2024

What Kinds Of Common Globe Valves Are There

- Dec 14, 2024

What are Inverted Bucket Steam Traps?

- Aug 29, 2025

What Are The Related Notices For The Check Valve?

- Dec 14, 2024

Related Articles from China Manufacturers

What is Double Block and Bleed Valves ?

- May 08, 2019

The Differences Between Ball Valves and Globe Valves

- May 10, 2019

What is difference between DBB and DIB ball valves?

- Feb 28, 2023

Monoflange, Double Block & Bleed Valves

- Nov 25, 2021

Double Block & Bleed Valves

- Feb 27, 2023

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Address: Dongou Industrial Zone, Oubei, Wenzhou, Zhejiang, China

- Phone: 86 577 5798 7171

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/what-are-double-block-and-bleed-ball-valves.html